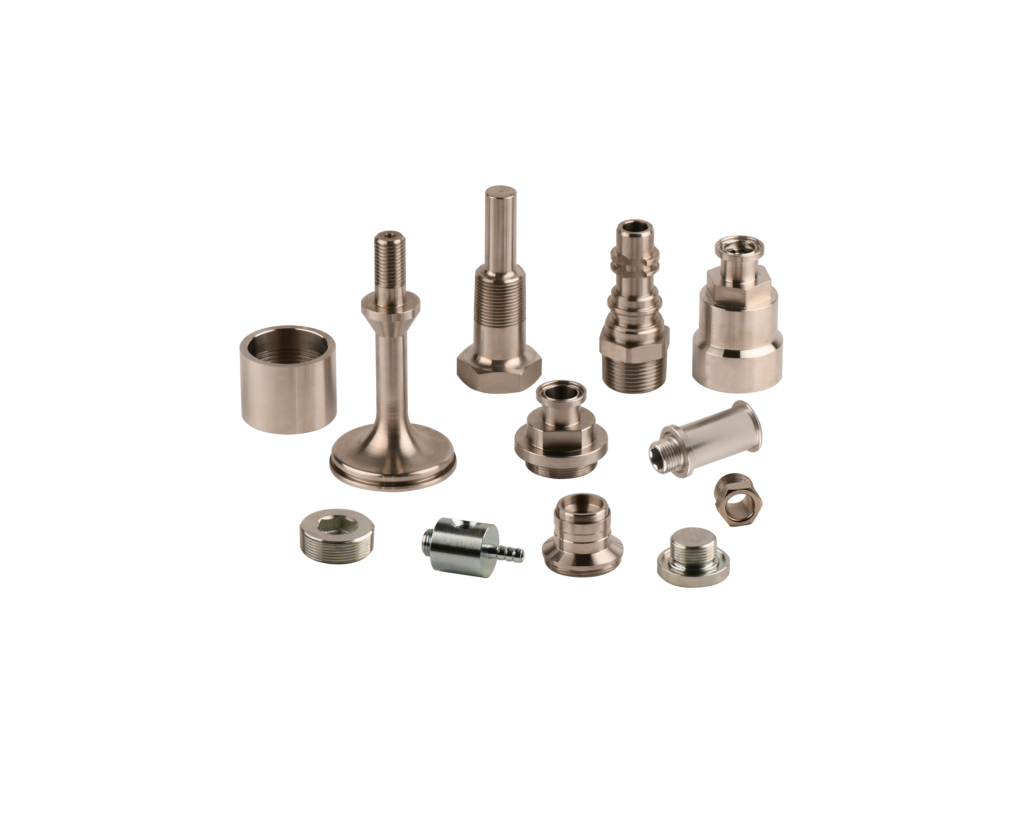

As a professional pipe fittings manufacturer with 8+ years of CNC experience, we are often asked: “Is 316 worth the extra cost over 304?” While they look identical to the naked eye, choosing the wrong grade for your hex nuts, nipples, or hydraulic adapters can lead to catastrophic failure in the field.

Today, we analyze the 4 key differences from a manufacturing and engineering perspective to help you make the right choice.

1. Chemical Composition: The “Molybdenum” Factor

The most significant difference lies in the elements you can’t see.

-

304 Stainless Steel: Contains 18% chromium and 8% nickel. It is the industry standard for general-purpose fittings.

-

316 Stainless Steel: Includes 2%-3% Molybdenum (Mo). This single addition is the secret to its superior performance in harsh environments.

2. Corrosion Resistance: Pitting & Chlorides

For pipe fittings, corrosion resistance is the top priority.

-

304: Offers excellent resistance in most atmospheric conditions and freshwater applications.

-

316: Specifically designed to resist chloride-induced pitting. If your fittings are for marine environments, chemical processing, or salt-heavy coastal areas, 316 is non-negotiable.

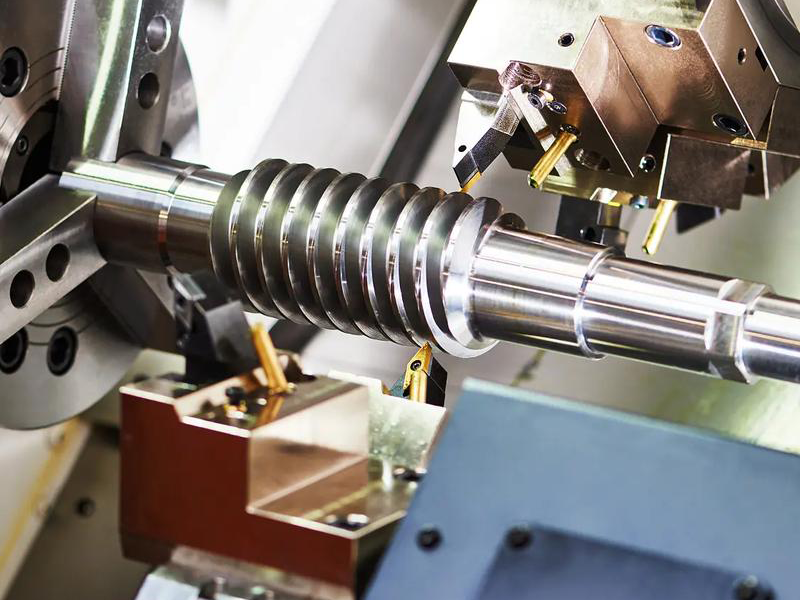

3. Machinability & Tooling Costs

From our CNC workshop’s perspective, stainless steel is notoriously “tougher” than carbon steel.

-

The 2-3x Rule: As we discussed previously, the tooling cost for machining stainless steel is 2 to 3 times higher than carbon steel.

-

316 vs. 304: 316 is slightly harder to machine than 304 due to its higher nickel content and work-hardening characteristics. This often reflects in a slightly higher labor cost for high-precision CNC turned parts.

Hardness Scale 304 Stainless Steel 316 Stainless Steel Brinell (HB) ≤ 187 – 201 ≤ 200 – 217 Rockwell (HRB) ≤ 90 – 92 ≤ 95 Vickers (HV) ≤ 200 – 210 ≤ 220

4. Cost vs. Performance Strategy

| Feature | 304 Stainless Steel | 316 Stainless Steel |

| Corrosion Resistance | Moderate (Excellent for general use) | High (Superior in saline/acidic areas) |

| Material Cost | Economical | Higher (Approx. 30-50% more) |

| Primary Use | Household, Food Tech, Standard Pipe | Marine, Medical, Chemical, Oil & Gas |

| CNC Difficulty | High (Compared to Carbon Steel) | Very High (Requires specialized tools) |

Conclusion: Stop Paying for Over-Engineered Parts

If your project involves food processing or indoor plumbing, 304 stainless steel pipe fittings offer the best ROI. However, for offshore oil rigs or medical-grade fluid systems, 316 is the only safe choice.

At Yuhuan Hongqian Machinery Co., Ltd, we specialize in custom CNC turning for both 304 and 316 stainless steel. Whether you need a high-precision hex nut or a complex hydraulic fitting, we ensure every thread meets your exact tolerance.