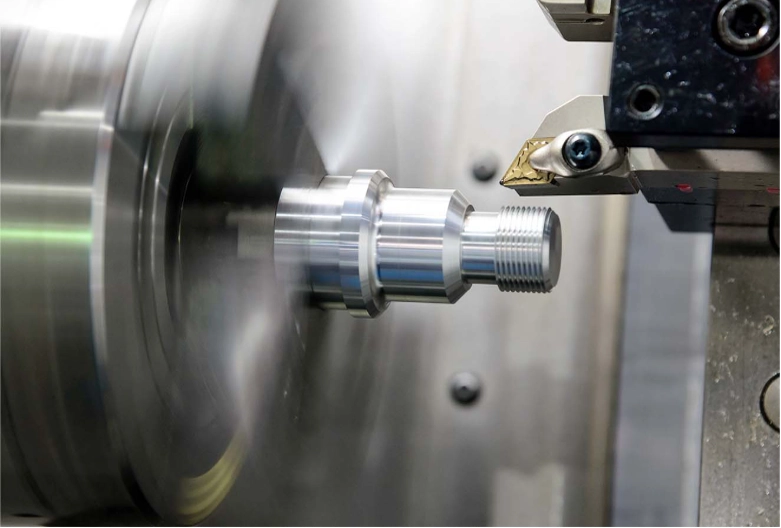

CNC thread machining is widely used in industries such as aerospace ,hydraulic and automotive manufacturing, where components like elbow hose connector ,hydrauclic adapter fitting ,screws, bolts, and nuts demand high precision and consistency. Achieving ideal accuracy in CNC threading requires careful planning, optimized tool selection, standardized programming, and rigorous quality control.

Online cnc turning services

Understanding CNC Thread Machining

CNC thread machining involves cutting helical grooves into a workpiece to create internal or external threads. CNC machines use specialized threading tools and precise programming to achieve exact dimensions, including pitch, depth, and lead angle. It belong to cnc turning process and produce by cnc lathe machine then could achieve the accurate and steady cnc progress.

Precision is crucial: even minor deviations can result in functional failures, such as threads that do not fit, components loosening over time, or thread disengagement under stress.

Challenges in Achieving CNC Threading Accuracy

| Challenge | Description | Impact on Accuracy |

|---|---|---|

| Tool wear | Threading tools wear over time | Can cause inconsistent thread depth and profile |

| Tool setup & alignment | Misalignment or improper centering | May result in uneven or skewed threads |

| Incorrect tool selection | Using tools incompatible with material or thread type | Leads to poor thread quality and inaccurate profiles |

| Feed rate & cutting speed errors | Improper cutting speed or feed rate | Can generate heat or vibration, causing thread distortion |

| Material hardness | different type material different thread cutter machine | Leads to tool wear, chatter, and difficulty maintaining tolerance |

| Thermal expansion | Heat generated during cutting | Causes deviations in thread depth and pitch |

| Chatter & vibration | Excessive vibration during cutting | Leads to poor surface finish and inconsistent thread geometry |

| Programming errors | CNC program mistakes in pitch, diameter, or depth | Threads may be undersized, oversized, or misaligned |

| Insufficient coolant | Inadequate or improper application of cutting fluid | Can cause overheating, tool wear, and poor surface finish |

| Complex geometries | Hard-to-reach or irregular areas | Harder to maintain consistent thread profiles |

Strategies and Best Practices to Ensure Precise CNC Threading

1. Select the Right Threading Tool

Choosing the correct threading tool greatly influences thread accuracy. Consider material type, thread size, and thread form (internal or external). Common tools include:

-

Thread turning inserts: Used for external threads, available in multiple profiles (ISO, UN, UNF ,NPT ,NPTF ,BSP,BSPT,ACME, etc.), precision-ground for consistent tooth form.

-

Thread milling cutters: Suitable for both internal and external threads, versatile and highly accurate.

-

Taps and dies: Taps for internal threads, dies for external threads. CNC tapping requires geometrically precise tools to maintain thread accuracy.

Tool material matters: For stainless steel, carbon steel , titanium, or hardened alloys, carbide tools are preferred due to wear resistance and durability.

2. Tool Setup and Calibration

Even the best CNC tools cannot guarantee accuracy if not properly set up. Key steps include:

-

Tool alignment: Misalignment causes uneven thread profiles. Use precision holders, collets, and alignment gauges.

-

Tool length compensation: Accurate compensation prevents overcutting or undercutting. Advanced CNC systems can dynamically adjust for tool length changes.

-

Tool wear monitoring: Continuous cutting wears tools and affects tolerances. Monitor and replace or regrind tools before performance degrades.

Online cnc turning services

3. Optimize CNC Threading Programs

Threading accuracy heavily depends on program quality. Consider:

a. Correct Thread Parameters

Include precise values for pitch, major/minor diameter, thread depth, and lead angle. Minor deviations can render threads unusable.

-

Pitch: Follow thread standards strictly.

-

Major/Minor diameter: Control within tolerance for proper mating.

-

Lead angle: Correct lead angle ensures smooth engagement.

b. Cutting Speed and Feed Rate

Control cutting speed and feed precisely. High speeds can generate heat and deflect tools; low feed rates may damage surface finish and accelerate tool wear.

Typically, threading uses slower speeds than other operations. CNC machines with synchronized spindle and feed control provide higher accuracy.

c. Thread Cutting Cycles

CNC machines offer preconfigured threading cycles such as G76, G32, or G92. Selecting the appropriate cycle improves accuracy and reduces programming complexity.

4. Coolant and Lubrication

Adequate cooling and lubrication are essential for tool life and thread accuracy. Coolant reduces heat, prevents tool wear, and limits thermal expansion. Lubrication lowers friction between tool and workpiece, ensuring smoother cutting and better surface finish.

High-pressure or mist coolant systems are recommended for materials prone to heat generation, like stainless steel or aluminum alloys.

5. Quality Control and Inspection

Even with optimal setup, strict inspection ensures threads meet specifications. Common methods:

-

Thread gauges: Go/no-go gauges for internal and external threads.

-

Optical measurement: Non-contact systems for precise pitch, angle, and profile measurement.

-

Coordinate measuring machines (CMMs): For complex parts requiring exact thread geometry.

Regular in-process checks help detect deviations early and reduce scrap.

6. Solving Common Threading Issues

-

Vibration: Causes poor finish and dimensional errors. Reduce cutting speed, increase tool rigidity, or adjust tool paths.

-

Inconsistent thread depth: Often due to tool wear, setup errors, or feed issues. Regular monitoring and program adjustments solve this.

-

Incorrect thread profile: Typically from wrong tools or program errors. Ensure tool profile matches thread standard and program is correct.

Conclusion

Achieving precise CNC threading requires a comprehensive approach: choosing the right tools, optimizing programming, maintaining proper cooling, and implementing strict quality control. By following these best practices, manufacturers can produce high-precision threads that meet stringent industry requirements.

Related topic :