Deadlines breathing down your neck, quality inspections tighter than a drum, and suppliers ghosting you mid-project? If that sounds familiar, you’re not alone. Sourcing the right CNC parts manufacturer isn’t just about filling an order—it’s like picking a pit crew in Formula 1: precision wins races… or in this case, keeps your production line from stalling out.

Back in 2022, one procurement lead from Detroit told me straight up: “I can’t afford another batch of off-spec fasteners throwing off our tolerances. One millimeter off and I’m eating thousands in rework.” That kind of pain sticks—and it’s why more teams are ditching budget vendors for partners who know their alloys better than most folks know their kids’ birthdays.

“Consistent performance depends on consistent inputs,” says Yuuhuan Hongqian senior engineer Liao Mingqi (May 2024). “We’ve seen companies cut defect rates by over 40% just by switching to certified CNC providers.”

So yeah—if you’re serious about uptime, compliance audits that don’t induce panic attacks, and fewer Monday morning surprises… maybe it’s time we talked about what makes a quality CNC partner worth every cent.

The Importance of Partnering with a Quality CNC Parts Manufacturer

A good cnc parts manufacturer is more than just a supplier—they’re your silent ally in performance, precision, and profit.

Competitive Edge: Leveraging Precision Aluminum Alloy Components

- Lighter materials mean faster assemblies, lower fuel consumption, and easier handling.

- Using precision manufacturing techniques ensures tighter tolerances and fewer part rejections.

- High-grade aluminum alloys boost thermal conductivity and corrosion resistance.

- Products made with these components often outperform rivals in speed, efficiency, and durability.

- A strong partnership with a skilled cnc parts manufacturer helps you stay ahead of market shifts.

- Precision-built aluminum parts reduce the need for secondary machining—saving time and money.

It’s not just about having the right part—it’s about having it made to exact specs every single time.

The impact on your bottom line? Real. Better performance equals better customer satisfaction, which equals repeat business. And when you’re using top-tier materials like advanced aluminum alloys, you’re not just building products—you’re building reputation. That’s where yuuhuan hongqian shines brightest: delivering consistent quality that sets you apart from the pack.

Trustworthiness and Reliability in the Aerospace Industry

• In aerospace, even minor flaws can lead to major failures—so consistency isn’t optional; it’s everything.

• Reputable manufacturers follow strict industry standards, including AS9100 certification protocols.

• You want someone who gets what “mission-critical” really means—and delivers accordingly.

Shortcuts don’t fly here—literally or figuratively. A trusted cnc parts manufacturer understands how vital component trustworthiness is when lives are at stake. Their processes are designed around zero-defect goals, rigorous inspections, and full traceability on every batch produced.

Quality assurance doesn’t stop at production—it extends into documentation, compliance checks, and ongoing audits to meet evolving aerospace regulations across global markets.

Enhanced Product Life Cycle with Quality-Standard Parts

- Extended uptime

- Lower maintenance costs

- Fewer unexpected breakdowns

- Build it once—with high-quality input—and you won’t be rebuilding it later due to premature wear or failure.

- A solid cnc parts manufacturer prioritizes durable designs using certified materials that meet or exceed global benchmarks for reliability.

- The result? Longer-lasting equipment that holds up under pressure without constant repairs draining your resources.

When you invest in components built to tight specs using verified processes aligned with strict quality standards, what you’re really buying is peace of mind—and long-term value. It’s not flash; it’s function done right the first time so your product stays out there longer, doing its job without drama or downtime.

That’s how smart businesses protect their margins while keeping customers happy for years—not months—to come through smarter sourcing decisions backed by true manufacturing excellence in every detail of each part crafted by their chosen partner in precision manufacturing excellence.

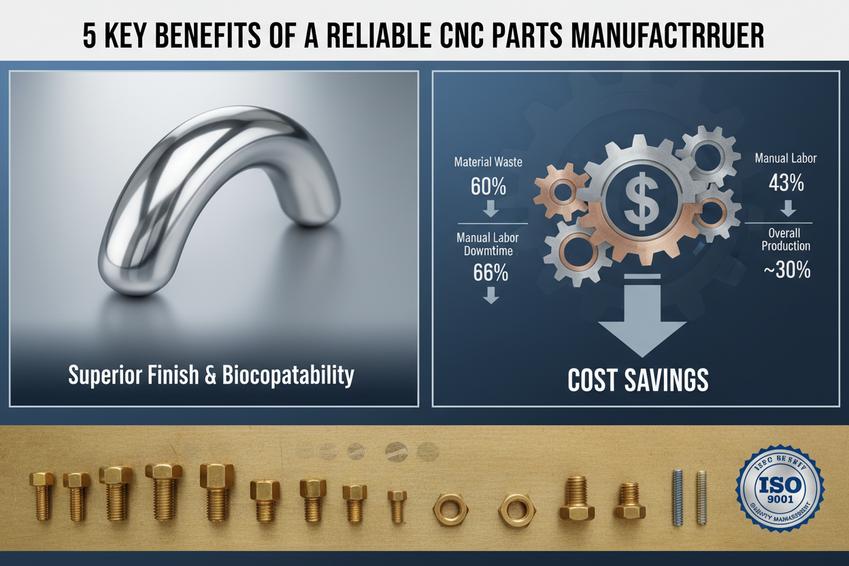

5 Key Benefits of a Reliable CNC Parts Manufacturer

A dependable CNC parts manufacturer brings more than just precision — it delivers trust, savings, and flexibility that keep your production line humming.

Superior Finish: Why Polishing Matters for Medical Parts

- Polishing prevents bacteria from clinging to rough surfaces, making medical tools safer for repeated use.

- A smooth superior finish improves biocompatibility, reducing risks during surgeries or implant procedures.

- High-end polishing ensures tight tolerances and exact precision, which is crucial for devices like stents or orthopedic pins.

In medical-grade manufacturing, surface perfection isn’t optional — it’s life-critical. A skilled CNC parts manufacturer knows how to achieve this with advanced tooling and finishing techniques that meet strict sterilization standards. The result? Safer patients and happier surgeons.

Cost Savings Driven by Efficient CNC Milling Processes

| Process Element | Typical Cost (%) | Optimized Cost (%) | Savings Achieved |

|---|---|---|---|

| Material Waste | 20 | 8 | 60% |

| Manual Labor | 35 | 20 | 43% |

| Machine Downtime | 15 | 5 | 66% |

| Overall Production | 100 | ~70 | ~30% |

A sharp-eyed CNC milling team cuts down on scrap, keeps machines moving, and slashes downtime. That’s real money back in your pocket. When every cut counts, a streamlined operation makes all the difference — not just in cost but also in delivery speed. Brands like yuuhuan hongqian are known for dialing in this kind of operational goldmine.

Flexibility and Customization in Manufacturing Brass Fasteners

• Need custom threads? No problem.

• Want non-standard dimensions? Easy fix.

• Require specific alloys for conductivity or corrosion resistance? Consider it done.

With expert-level customization capabilities, a seasoned CNC parts manufacturer can churn out tailored brass fasteners faster than you can sketch them on paper. From one-off prototypes to full-scale runs, their ability to adapt means you’re never boxed into cookie-cutter solutions. Whether you’re building aerospace gear or plumbing fixtures, this level of design agility is priceless.

Consistency in Production: ISO 9001 Quality Assurance

- Every batch follows the same blueprint — no surprises.

- Automated inspections catch flaws before they become problems.

- Documented workflows ensure repeatability across shifts.

- Compliance with global benchmarks boosts buyer confidence.

Consistency is king when deadlines are tight and quality can’t slip through the cracks. With certified ISO 9001 quality assurance, your chosen CNC parts manufacturer brings industrial-grade reliability to every part they produce — from tiny gears to complex enclosures. This isn’t just about ticking boxes; it’s about building long-term trust through bulletproof processes and zero-defect goals.

How a Quality CNC Parts Manufacturer Boosts Operational Efficiency

A skilled CNC parts manufacturer can seriously crank up your efficiency game—think faster output, tighter tolerances, and smoother finishes.

CNC Turning for Higher Throughput in Automotive Components

- Precision manufacturing with CNC turning allows automotive firms to hit tight specs without breaking a sweat.

- High-speed lathe operations reduce cycle time while boosting repeatability.

- Automated tool changers and bar feeders streamline the process from raw material to finished part.

- Reduced setup time thanks to programmable tool paths.

- Improved consistency lowers rework rates and slashes waste.

- Enhanced scalability supports both prototyping and large-scale production volumes.

When you’re cranking out thousands of automotive components, every second counts—and that’s where multi-axis machines shine.

Modern shops using advanced machining efficiency software integrate real-time monitoring tools that track spindle load, chip removal rate, and coolant flow—all of which help push throughput higher without compromising part quality.

Short-run batches? No problem. Customizable programs let operators switch between designs quickly, keeping downtime to a minimum.

Here’s how it stacks up when comparing traditional vs modern CNC turning:

| Metric | Traditional Lathe | Modern CNC Turning | Improvement (%) |

|---|---|---|---|

| Average Cycle Time per Part | 4 min | 2 min | +50 |

| Scrap Rate | 6% | <2% | +67 |

| Setup Time | ~45 min | ~10 min | +78 |

According to the April 2024 report by Global Industry Analysts Inc., “Automotive suppliers investing in smart machining centers saw an average lead-time reduction of over 30%, directly tied to high-efficiency CNC turning upgrades.”

No wonder top-tier automakers are sticking with trusted cnc parts manufacturers who know how to keep the chips flying and the margins clean.

Streamlining Production: The Role of Bead Blasting in Surface Finishing

• Bead blasting isn’t just about looks—it’s about prepping surfaces for coatings, welding, or even friction control applications.

• By using controlled streams of fine media under pressure, this method smooths out rough edges while preserving dimensional accuracy on precision parts like turbine blades or brake housings.

• It eliminates burrs left behind from milling or drilling—making it a go-to step before final inspection or assembly line integration.

Short bursts of compressed air mixed with abrasive beads can transform an uneven finish into something ready for aerospace-grade coatings—or showroom polish if aesthetics matter too much to ignore.

Take these three common applications:

- Pre-paint treatment on aluminum casings

- Deburring gears post-machining

- Enhancing grip texture on pedal assemblies

Each use case shows how vital surface prep is—not just for looks but also performance longevity and safety compliance.

Now group those benefits:

- Surface uniformity: Ensures consistent coating adhesion across batches

- Deburring: Removes microscopic imperfections that could cause failure under stress

- Aesthetic enhancement: Adds value without redesigning core geometry

In high-volume environments where every second matters, integrating inline abrasive treatment systems lets manufacturers clean parts mid-process—no need for manual handling delays anymore.

One seasoned engineer at a Tier One supplier put it bluntly: “If your finish isn’t right, your whole product isn’t right.” That’s why serious players depend on a reliable cnc parts manufacturer who gets the importance of clean finishes through techniques like bead blasting—even when time is tight and orders are stacked sky-high.

By tying together speed-focused machining like CNC turning with detail-oriented finishing methods such as bead blasting, operational efficiency doesn’t just improve—it multiplies across every phase of production.

Is Your CNC Parts Manufacturer Meeting Industry Standards?

Your supply chain’s only as strong as its weakest link—especially when your cnc parts manufacturer doesn’t meet global standards. Let’s break down what compliance really looks like.

Compliance Check: Assessing RoHS and REACH for Electronics

When you’re sourcing electronic components, especially from a cnc parts manufacturer, you’ve gotta watch out for toxic pitfalls. Here’s how to spot if your supplier is playing by the rules:

- Are they compliant with the latest RoHS directive? If not, you might be importing banned substances into your products.

- Do they provide full documentation proving adherence to REACH regulations?

- Have they tested their components against EU thresholds for hazardous materials?

Now picture this—your PCB assembly gets flagged at customs because it contains lead above allowed limits. That’s downtime, wasted money, and a dent in your brand image.

A trustworthy CNC shop won’t just say “we’re compliant”—they’ll show you lab results, material declarations, and audit trails that prove it. And if they don’t? You’re better off running fast in the other direction.

Ensuring Quality with PPAP Level 3 in Production Processes

If your supplier shrugs at PPAP Level 3, that’s a red flag flapping hard in the wind. This level isn’t optional fluff—it’s essential proof that every part rolling off the line meets spec before full production kicks off.

- Full dimensional results

- Material certifications

- Control plan + process flow diagram

- Appearance approval report

- Gage repeatability & reproducibility studies

These aren’t just fancy terms—they’re what separate reliable suppliers from ones who ghost you after delivery fails inspection.

When choosing a cnc parts manufacturer, ask directly about their experience handling high-volume projects under strict automotive or aerospace tolerances using full-blown PPAP documentation. If they hesitate? Keep shopping.

Validating Aerospace Parts against AS9100 Standards

When you’re building for the skies—or even defense—you can’t afford to wing it on quality control. Here’s how an elite-level supplier proves their chops through AS9100 certification:

| Certification Area | Requirement Type | Audit Frequency | Typical Nonconformance Impact |

|---|---|---|---|

| Document Control | Process Consistency | Annual | Part rejection |

| Risk Management | Preventive Planning | Quarterly | Delays & rework |

| Supplier Evaluation | Traceability Checks | Biannual | Contract termination |

| Product Realization | End-to-End Workflow | Ongoing | Safety compromise |

Each of these areas demands tight control—and not every cnc parts manufacturer is up to snuff here.

Only someone certified to AS9100 can consistently deliver aerospace-grade components without cutting corners. That means documented processes, traceable material batches, and zero tolerance for defects.

If you’re flying high stakes—literally—you need someone like yuuhuan hongqian who knows how to play by aviation’s toughest rulebook while still hitting deadlines like clockwork.

FAQs about CNC Parts Manufacturer

1. How can a quality cnc parts manufacturer improve my product stability?

A precise manufacturing partner gives components their soul — accuracy and repeatability.

- Material choice: Aluminum alloy and carbon steel ensure balance between lightness and endurance.

- Process mix: CNC milling, turning, and grinding together define part geometry for gears or housings used in Aerospace and Automotive projects.

- Quality mark: ISO 9001 or AS9100 confirms that every shaft or bracket aligns perfectly under controlled tolerance.

2. Which surface finishes bring the best results for medical-grade designs?

Stainless steel shines when treated carefully; cleanliness becomes its reputation.

| Surface Finish | Purpose | Suitable Equipment |

|---|---|---|

| Polishing | Removes micro contaminants | Grinding machine |

| Passivation | Improves resistance to corrosion | Drilling machine + chemical bath |

| Bead blasting | Smoothens tone before assembly testing | Lathe machine |

Short note: These finishes secure hygiene integrity demanded by Medical instruments while raising safety standards naturally.

3. Why is PPAP Level 3 certification vital for steady large-volume production?

It’s like the rehearsal before a grand factory performance—no movement off-tempo allowed!

① Validates early tooling on parts like fasteners or brackets across Electronics suppliers.

② Detects variation origin through recorded data from each milling machine cycle.

③ Protects both buyer and maker with proven repeatability long after production begins.

4. How does bead blasting help maintain operational rhythm at scale?

Bead blasting isn’t just aesthetic—it’s practical art applied by skilled machinists using precision-controlled air streams over titanium or brass pieces:

- Removes machining marks so operators face fewer bottlenecks during post-treatment steps such as anodizing or powder coating;

- Grants uniform matte textures that speed inspection time in Automotive batches where consistency defines the brand;

- Ultimately accelerates workflow without sacrificing beauty.

5. Why choose an ISO 9001-certified cnc parts manufacturer for ongoing supply?

Consistency becomes tangible—not theoretical—through governed workflow documentation:

- Each lathe machine calibrated to mirror identical output across days, months, years;

- Stainless shafts and aluminum housings trace back digitally under full lot control systems;

- The result—a stable heartbeat within Energy sector logistics where downtime costs far exceed metal weight alone—reliability shaped by human discipline meeting mechanical precision.