CNC turning is one of the most widely used machining processes in modern manufacturing. From simple cylindrical components to complex precision fittings, CNC turned parts play a critical role across industries such as automotive, hydraulics, aerospace, electronics, and industrial equipment.

Understanding what CNC turning processes are, how they work, and why each operation matters helps engineers, buyers, and product designers make better decisions when sourcing CNC parts. This article explains the core CNC turning operations—from facing to threading—and shows how advanced turn-mill capabilities expand what a CNC machine can achieve.

What Is CNC Turning and Why It Is Essential for CNC Turned Parts

CNC turning is a machining process where a rotating workpiece is shaped by a stationary cutting tool. Unlike milling, where the tool rotates, CNC turning relies on controlled rotation of the material to produce precise round, cylindrical, or symmetrical features.

This process is especially suitable for producing high-precision CNC turned parts with tight tolerances, excellent surface finishes, and repeatable accuracy. Modern CNC machines allow multiple turning operations to be completed in a single setup, reducing errors and improving efficiency.

Facing Operation in CNC Turning

What Is Facing in CNC Turning?

Facing is one of the most fundamental operations in CNC turning and is typically the first machining step performed on a CNC lathe. The purpose of facing is to create a flat, smooth surface that is perpendicular to the rotational axis of the workpiece, ensuring accurate part length and dimensional consistency.

During a facing operation, the workpiece is clamped in a chuck and rotated at a controlled spindle speed. A single-point cutting tool moves radially from the outer diameter toward the center, removing excess material from the end face. This process eliminates saw marks, uneven stock, and surface deformation commonly found on raw bar stock or cut blanks.

In professional CNC turning services, a properly faced surface is critical because it serves as the Z-axis datum reference for subsequent operations such as OD turning, drilling, boring, threading, and grooving. Any error at this stage can directly affect hole depth, thread position, and overall part length.

Why Facing Is Critical for CNC Turning Accuracy

In high-precision CNC turning, facing is not just a surface-finishing step—it defines the reference point for the entire machining process. Once the end face is established, all axial dimensions are measured from this surface, making facing essential for tight tolerances and repeatable results.

Industries such as automotive, hydraulics, industrial equipment, and precision hardware manufacturing rely on accurate facing to maintain consistency across high-volume production runs. When facing is performed correctly, it improves dimensional control, enhances surface finish, and reduces the risk of downstream machining errors.

For CNC turning manufacturers serving global markets, consistent facing quality also ensures compatibility with international standards and customer specifications.

Common Facing Problems in CNC Turning and How to Prevent Them

Center Pip Formation During Facing

One common issue in CNC turning facing operations is the formation of a small raised point at the center of the workpiece, often referred to as a center pip. This defect occurs when the cutting tool does not fully cross the spindle centerline. At the center of the rotating part, cutting speed approaches zero, causing material to deform rather than be cleanly removed.

To prevent center pip formation, the cutting tool should slightly pass beyond the centerline during the facing cycle. In precision CNC turning, fine adjustments to tool offsets or nose radius compensation can also be applied. Proper centerline control results in a smooth, flat end face and improved surface quality.

Tool Height and Surface Finish Issues

Incorrect tool height is another frequent cause of poor facing results. If the tool is set above or below the true center, it can lead to uneven surfaces, excessive tool wear, or visible machining marks. Optimizing feed rates, tool geometry, and cutting parameters is essential for achieving a clean, professional finish in CNC turning applications.

Facing as the Foundation of High-Quality CNC Turning

Facing establishes the foundation for all subsequent CNC turning operations. A flat, accurate end face ensures stable machining, precise measurements, and consistent quality across production batches. For manufacturers providing CNC turning services to international customers, mastering facing operations is a key indicator of machining capability and process control.

Typical Applications

Facing is commonly used for:

-

Shafts and pins

-

CNC turned fittings

-

Bushings and spacers

-

Hydraulic and pneumatic components

Proper facing directly affects the dimensional consistency of finished CNC parts.

OD Turning in CNC Turning: Shaping the External Diameter

After the facing operation establishes a precise Z-axis reference surface, OD (Outer Diameter) turning is performed to shape the external geometry of the part. OD turning defines the final outside diameter, roundness, straightness, and surface finish, making it one of the most critical operations in CNC turning.

During OD turning, the cutting tool moves parallel to the spindle axis while the workpiece rotates at a controlled speed. This operation may involve multiple passes, including rough turning to remove bulk material and finish turning to achieve tight dimensional tolerances and smooth surface quality.

Typical CNC OD turning applications include shafts, cylindrical housings, threaded connectors, and precision sleeves. In high-precision CNC turning, OD accuracy directly affects part fit, bearing performance, sealing efficiency, and overall mechanical reliability.

Proper tool selection, stable tool engagement, and optimized cutting parameters are essential to prevent chatter, taper, or surface defects during OD turning.

ID Turning (Internal Turning): Precision Inside the Bore

ID turning, also known as internal turning, machines the inner surface of a hole or bore after drilling or rough boring. This CNC turning operation is used when tight internal tolerances, concentricity, and smooth bore finishes are required.

Compared to OD turning, ID turning presents greater challenges due to limited tool rigidity and increased tool overhang. Internal cutting tools must maintain stability while operating inside confined spaces, making vibration control and tool geometry especially important.

ID turning is commonly applied in CNC turned parts such as bushings, hydraulic components, bearing housings, and precision sleeves. When performed correctly, internal turning ensures accurate bore diameter, consistent wall thickness, and proper alignment with the external features of the part.

Precision Control Considerations for OD and ID Turning

Achieving high-quality results in CNC OD and ID turning requires careful control of multiple machining factors. Key precision considerations include:

-

Tool rigidity and overhang control to minimize vibration

-

Proper cutting parameters for the selected material

-

CNC machine stability and spindle condition

-

Consistent material quality and hardness

High-quality CNC turned parts depend on minimizing tool deflection, controlling thermal expansion, and maintaining stable cutting conditions throughout the turning cycle. Poor control in these areas can lead to dimensional drift, poor surface finish, or premature tool wear.

Grooving Operations in CNC Turning: Creating Functional Slots

Grooving is a CNC turning operation used to cut narrow channels into a part’s outer diameter (OD) or inner diameter (ID). These grooves often serve functional, sealing, or assembly-related purposes, and require precise width, depth, and location control.

Common CNC grooving applications include O-ring grooves for sealing, snap-ring grooves, and retaining features in mechanical assemblies. Because grooves are typically narrow, improper tool alignment or excessive cutting forces can easily cause tool breakage or dimensional errors.

Precision grooving ensures reliable sealing performance, secure component retention, and long-term assembly stability in CNC turned parts.

Parting Operations: Separating the Finished CNC Turned Component

Parting, also referred to as cut-off, is the final operation in most CNC turning processes. It separates the finished component from the raw bar stock, making it a critical step for both dimensional accuracy and surface integrity.

A stable parting operation depends on correct tool alignment, appropriate feed rates, adequate coolant flow, and sufficient spindle rigidity. Poor parting control can result in burr formation, tool breakage, or surface damage on the finished part, especially in small-diameter or thin-walled components.

In professional CNC turning services, parting is carefully optimized to ensure clean separation, consistent part length, and minimal secondary deburring requirements.

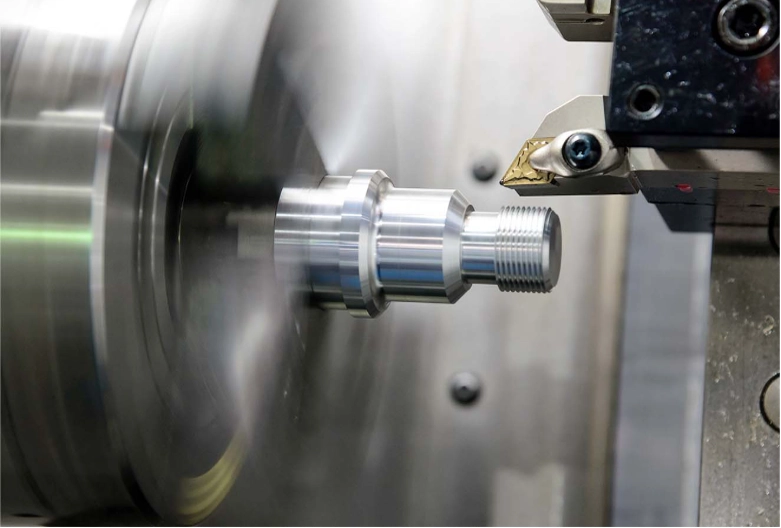

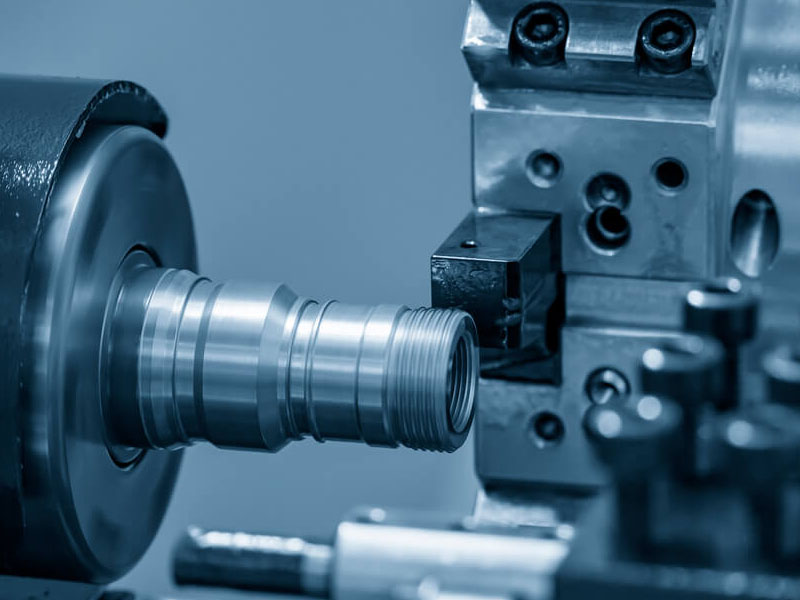

External Thread Turning in CNC Turning

Following OD turning and grooving operations, external thread turning is used to create precise threads on the outer surface of CNC turned parts. This CNC turning process allows accurate control over thread form, pitch, depth, and lead, making it ideal for components that require reliable mechanical connections.

External thread turning is commonly applied in CNC turned parts such as pipe fittings, fasteners, hydraulic connectors, and industrial couplings. Compared with rolling or die threading, CNC thread turning provides greater flexibility for non-standard thread profiles, custom pitches, and tight tolerance requirements.

In precision CNC turning, correct synchronization between spindle rotation and tool feed is critical. Any deviation can result in pitch errors or poor thread engagement, directly affecting part assembly and sealing performance.

Internal Thread Turning: Precision Threads Inside the Bore

Internal thread turning is used to machine threads inside a drilled or bored hole. Unlike traditional tapping, CNC internal thread turning offers improved control, especially for large-diameter threads, deep internal threads, or special thread geometries.

Because internal threading tools operate inside confined spaces, tool rigidity and vibration control play a major role in thread quality. CNC turning machines enable precise control of cutting parameters, allowing consistent thread depth and accurate profile reproduction across production batches.

For high-performance CNC turned parts, internal thread turning often delivers better repeatability and surface finish than tapping, particularly in harder materials or tight-tolerance applications.

Common Thread Accuracy Challenges in CNC Turning

Maintaining thread accuracy in CNC turning requires careful attention to several machining variables. Common challenges include tool wear, which gradually alters thread profile, incorrect pitch synchronization between the spindle and feed axis, and material spring-back, which can affect final thread dimensions.

In addition, inadequate inspection methods may fail to detect minor thread defects that later cause assembly issues. For critical CNC turned components, thread turning on CNC lathes typically provides higher consistency and better dimensional control compared to traditional tapping processes.

Drilling Operations on CNC Turning Centers

After facing and turning operations establish external geometry, drilling is used to create initial axial holes along the centerline of the rotating workpiece. On CNC turning centers, drilling is a fast and efficient method for producing concentric holes with high positional accuracy.

Typical drilling applications in CNC turning include pilot holes, through-holes for fasteners, and internal fluid passages in fittings and connectors. Because drilling is performed in the same setup as turning, it minimizes alignment errors and improves overall machining efficiency.

Boring: Achieving High-Precision Internal Diameters

Boring is performed after drilling to enlarge and refine internal holes to precise dimensions. In CNC turning, boring improves diameter accuracy, roundness, straightness, and surface finish, making it essential for parts requiring tight internal tolerances.

Boring tools allow fine adjustments to achieve exact internal diameters while maintaining concentricity with the external features produced during OD turning. For precision CNC turned parts, boring ensures reliable fit, proper sealing, and consistent functional performance.

CNC Turning vs CNC Milling for Hole Machining

While CNC milling machines are capable of drilling and boring holes, CNC turning centers are more efficient for coaxial and rotationally symmetric features. Turning machines excel at producing holes that must remain perfectly aligned with the part’s central axis.

For high-volume production of CNC turned components, CNC lathes reduce setup time, improve consistency, and deliver better cost efficiency compared to secondary milling operations.

Multi-Axis and Turn-Mill CNC Turning Capabilities

As CNC part complexity increases, multi-axis CNC turning centers and turn-mill machines offer significant advantages. Turn-mill machining combines CNC turning and CNC milling capabilities in a single setup, allowing complex features to be produced without repositioning the part.

Multi-axis CNC machines reduce setup time, improve positional accuracy, and eliminate many secondary operations. They are particularly effective for CNC turned parts that require cross-holes, flats, keyways, or angular features.

When to Choose Turn-Mill CNC Turning Solutions

Turn-mill CNC turning is recommended when parts require tight tolerances across multiple features, complex geometries, or when secondary milling increases production cost and risk.

For advanced CNC turned parts, turn-mill machining improves both manufacturing efficiency and overall part quality by maintaining consistent datum alignment throughout the machining process.

Why Understanding CNC Turning Processes Improves Part Quality

A clear understanding of CNC turning processes helps engineers and buyers select the right machining approach, optimize part designs for manufacturability, reduce machining costs, and improve long-term part performance.

High-quality CNC turned parts are the result of an integrated process that includes facing, turning, grooving, threading, drilling, and boring—executed as a unified CNC turning strategy rather than isolated steps.

Conclusion: How CNC Turning Processes Define High-Quality CNC Parts

CNC turning remains the backbone of precision machining. From basic facing operations to advanced multi-axis turn-mill machining, each CNC turning process contributes directly to part accuracy, consistency, and reliability.

By understanding what each CNC turning operation does, how CNC machines perform it, and why it matters, manufacturers and buyers can achieve tighter tolerances, better surface finishes, and more cost-effective production of CNC turned parts.

CNC Turning FAQ

Q1: What is CNC turning?

A: CNC turning is a machining process where a rotating workpiece is shaped by a stationary cutting tool, ideal for cylindrical and round parts.

Q2: What parts can CNC turning produce?

A: Shafts, pins, bushings, spacers, hydraulic components, threaded connectors, and precision sleeves.

Q3: What are common CNC turning operations?

A: Facing, OD/ID turning, grooving, parting, threading, drilling, and boring.

Q4: How to ensure precision in CNC turned parts?

A: Proper tool selection, spindle stability, cutting parameters, and accurate Z-axis referencing.

Q5: What are the benefits of turn-mill CNC turning?

A: Combines turning and milling in one setup, reducing setup time, improving accuracy, and lowering production cost.

Q6: Common CNC turning problems and prevention?

A: Center pip, tool wear, chatter; prevent with proper tool alignment, cutting parameters, and coolant use.