As a CNC turned parts manufacturer, we operate more than 80 CNC lathes and employ over 30 experienced staff. We have extensive experience producing custom CNC turned parts for various industrial applications.

We can quickly review customer 2D or 3D drawings and determine the most cost-effective way to select blanks and define the production method.

Compared with a standard CNC parts factory, we are experienced in meeting diverse customer requirements, including material selection, tolerance control, and surface treatment.

What the different bettween stand part factory and cnc turning parts manufacturer ?

1. Standard Part Factory

-

Focus: Mass production of pre-designed, widely used parts.

-

Product Examples: Nuts, bolts, screws, washers, flanges, and other catalog parts.All nut and bolts etc have the same standard and standard parts factory can sell same goods to different customers .

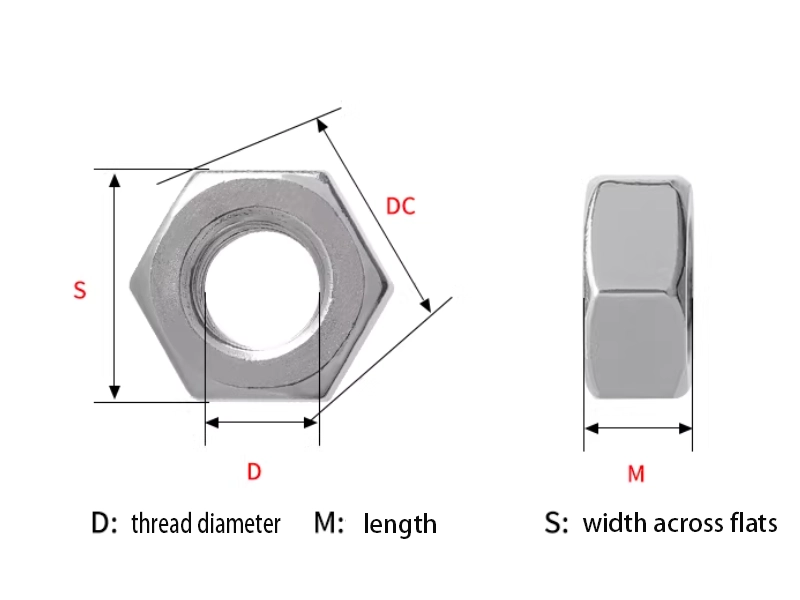

For example of ss nut , based on the Hex Nut Dimension Table , we can clear the all detail size for the nut and choose the item easily .

Hex Nut Dimension Table

| Thread (M) | Pitch (mm) | Width Across Flats (S, mm) | Thickness (M, mm) | Across Corners (DC, mm) |

|---|---|---|---|---|

| M1 | 0.25 | 2.5 – 2.4 | 1.2 – 1.1 | 2.7 – 3.2 |

| M1.2 | 0.25 | 2.5 – 2.4 | 1.2 – 1.1 | 3.2 – 3.4 |

| M1.4 | 0.3 | 2.6 – 2.5 | 1.2 – 1.1 | 3.2 – 3.4 |

| M1.6 | 0.35 | 3.1 – 3.0 | 1.2 – 1.1 | 3.2 – 3.4 |

| M2 | 0.4 | 4.0 – 3.8 | 1.6 – 1.5 | 3.2 – 3.4 |

| M2.5 | 0.45 | 5.0 – 4.8 | 1.9 – 1.8 | 5.4 – 5.5 |

| M2.6 | 0.45 | 5.0 – 4.8 | 2.0 – 1.9 | 5.4 – 5.5 |

| M3 | 0.5 | 5.5 – 5.4 | 2.4 – 2.2 | 6.0 – 6.1 |

| M4 | 0.7 | 7.0 – 6.8 | 3.1 – 3.0 | 8.7 – 8.9 |

| M5 | 0.8 | 8 – 7.8 | 3.9 – 3.7 | 11.0 – 11.0 |

| M6 | 1 | 10 – 9.8 | 5.1 – 4.8 | 14.3 – 14.3 |

| M8 | 1 / 1.25 | 13 – 12.9 | 6.3 – 6.2 | 18.9 |

| M10 | 1 / 1.5 | 16.9 – 16.8 | 7.8 – 7.7 | 21.1 |

| M12 | 1.25 / 1.5 | 18.9 – 18.8 | 9.8 – 9.7 | 24.4 |

| M14 | 1.5 / 2 | 21.8 – 21.7 | 10.8 – 10.7 | 26.7 |

| M16 | 1.5 / 2 / 2.5 | 23.8 – 23.7 | 12.7 – 12.6 | 29.5 |

-

Production:

-

High-volume, standardized processes.

-

Little to no customization for individual customer specifications.

-

-

Pros:

-

Fast delivery, always can buy and keep in big stock in the market .

-

Lower cost per piece due to mass production.

-

-

Cons:

-

Cannot produce parts that deviate from the standard specifications.

- low standard quality but satisfy basic function .

-

2. Custom CNC Turned Parts Manufacturer

Focus:

A custom CNC turned parts manufacturer produces parts strictly according to customer drawings or technical specifications.

There are no “standard sizes” — every project is evaluated individually.

Production Characteristics:

-

Made-to-order manufacturing

-

Drawing review and engineering evaluation required

-

Low to big volume production based on factory demand .

-

Minimum order quantity (MOQ) applies

Before production, the cnc parts manufacturer must need confirm:

-

Study oversea material is equivalent to which type domestic material .

-

Study if the equipement could satisfy the cnc turned parts tolerance requirements

-

Study supply chain for cnc turning parts Surface treatment or coating

-

Study supply chain for Heat treatment or hardness

-

CNC machine and process suitability

Pros:

-

Fully customizable in size, tolerance, and function,surface treatment , thread (NPT,NPTF, METRIC,BSPP,BSPT,G,RP ,UNF,UNC,UNEF etc )

-

Suitable for non-standard, precision, or special applications

-

Better control of consistency for repeat batch orders

Cons:

-

Higher cost per piece than standard parts

-

Longer lead time due to drawing review and sample approval

-

Not suitable for urgent off-the-shelf purchases

Yuhuan Hongqian – China CNC Turning Parts Manufacturer

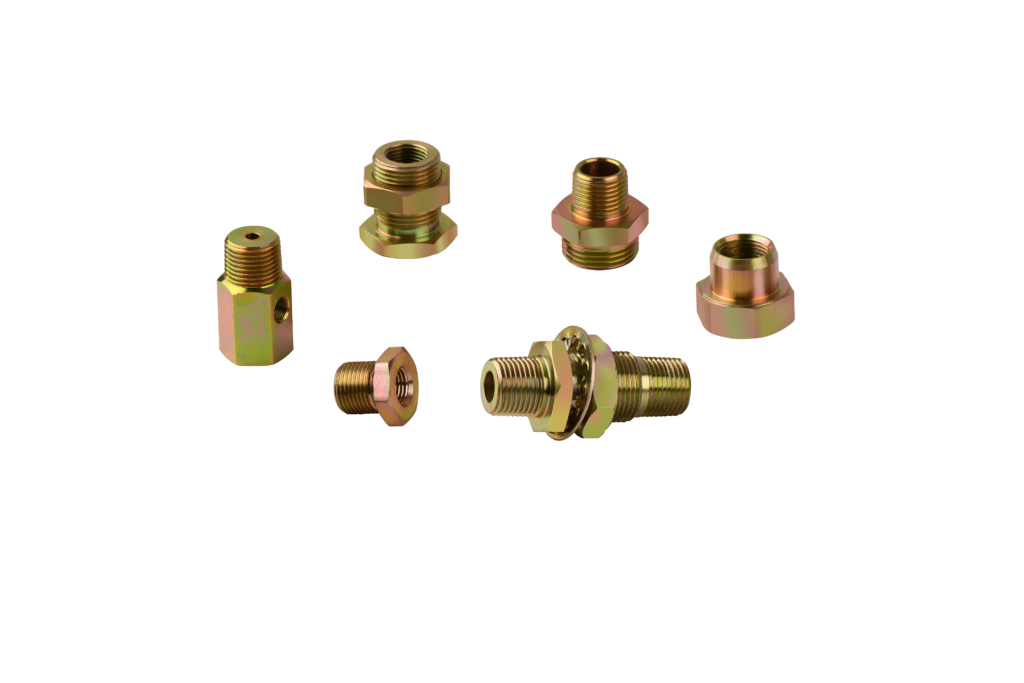

Yuhuan Hongqian is a professional China CNC turning parts manufacturer, specializing in custom CNC turned components for industrial applications.

As a direct machining factory, we focus on made-to-order production based on customer drawings and technical requirements. We provide OEM/ODM cnc turning service online .

Manufacturing Capability

Our factory is equipped with a complete set of machining, automation, and inspection equipment to support stable and efficient CNC turning production. 2000 square meter in yuhuan ,zhejiang province .

30 experienced staff work for different types of cnc turning parts , we produce include standard parts also can fast produce custom made cnc parts.

Machining Equipment

-

Over 80 CNC lathe machines

-

Automatic lathes

-

Gantry robotic loading systems

-

Automatic bar feeding machines

-

Sawing machines

-

Punching machines

-

Drilling machines

-

Tapping machines

-

Cutting machines

-

Laser marking machines

-

Demagnetizing machines

Inspection & Testing Equipment

-

Micrometers

-

Depth gauges

-

Profile projector

-

Hardness testers

-

Salt spray testing machine

With in-house inspection at every stage, we ensure parts strictly meet drawing and tolerance requirements.

Machining Range & Precision

-

Maximum machining size: up to 300 × 300 mm

-

Tolerance capability: up to ±0.01 mm, depending on part structure and material

Materials We Work With

As an experienced CNC turning parts manufacturer, we mainly process:

-

Carbon steel

We also support:

-

Brass

-

Aluminum

-

Alloy steel

Material selection is confirmed based on drawing requirements and application conditions.

Production Capacity

Our factory has a stable monthly output capacity of up to 300,000 pieces across different types of CNC turned parts.

Production volume can be adjusted according to part complexity, tolerance level, and surface treatment requirements.

Why Work with Yuhuan Hongqian

-

Direct CNC turning parts manufacturer, not a trading company

-

Strong equipment base with automated production support

-

Practical experience in custom and non-standard CNC turning parts

-

Stable quality for repeat batch orders

-

Clear communication from drawing review to mass production

CONCLUSION

At Yuhuan Hongqian, we focus on delivering practical, reliable CNC turned parts rather than marketing promises. Every part we produce goes through careful drawing review, precise machining, and in-house inspection to ensure it meets customer requirements.

Our team of experienced engineers and machinists works directly with each order, from prototype to mass production. We do not sell stock parts; we produce what you need, with the right material, tolerance, and surface finish.

This hands-on approach allows us to handle complex, non-standard, or precision parts consistently. If your project requires a trustworthy CNC turning parts manufacturer in China, our factory is ready to provide technical support and production expertise.