Custom CNC turning parts are essential in modern manufacturing, especially for industries requiring high precision, tight tolerances, and consistent repeatability. From hydraulic fittings and automotive components to industrial machinery and electronic hardware, our CNC turning services allow manufacturers to produce complex rotational parts with reliability and efficiency.

Whether you are an engineer, buyer, or product designer, this guide explains how our CNC turning manufacturing process delivers precision components tailored to your needs.

What Are Custom CNC Turning Parts?

CNC turning is a machining process where a workpiece rotates while a cutting tool removes material to produce precise cylindrical or rotational parts. Unlike manual lathes, CNC turning machines are computer-controlled, offering high accuracy, repeatability, and efficiency.

Custom CNC turning parts are made according to customer-specific drawings or requirements. “Custom” can include:

- Unique dimensions and tolerances

- Specific materials

- Functional features like threads, grooves, or internal bores

- Surface finishes

We provide both OEM CNC turning service and ODM CNC turning service to meet diverse manufacturing needs.

OEM CNC Turning Service: Precision Parts from Your Drawings

OEM CNC Turning Service: Precision Parts from Your Drawings

OEM CNC turning service means you provide complete drawings, and we manufacture exactly according to specifications.

- Customer owns the design

- We handle precision machining and quality control

- No design changes unless requested

Best for:

- Finalized designs

- Stable production needs

ODM CNC Turning Service: Design and Production Support

ODM CNC turning service allows our engineers to handle both design and machining.

- Customer provides an idea, sample, or functional requirement

- We optimize the design and produce the parts

- Reduces development time and cost

Best for:

- New product development

- Customers without in-house engineering

OEM vs ODM CNC Turning: How to Choose

| Item | OEM | ODM |

|---|---|---|

| Drawings | Provided by customer | Provided or supported by manufacturer |

| Design involvement | Minimal | High |

| Customization | Medium | High |

| Time to market | Standard | Faster |

| Best use | Mature products | New or optimized products |

Tip: Have drawings? Choose OEM. Need design support? Choose ODM.

CNC Turning Manufacturing Process Overview

Our CNC turning manufacturing process ensures precision, efficiency, and reliability. Each step is designed to meet your specifications:

- Design Review & Engineering Support

- Evaluate tolerances, concentricity, surface roughness

- Provide DFM suggestions to reduce cost and risk

- Material Selection for CNC Turning Parts

- Carbon Steel: cost-effective, strong

- Stainless Steel: corrosion-resistant

- Aluminum: lightweight, easy to machine

- Brass: excellent machinability and conductivity

- CNC Turning Operations Explained

- Facing, OD turning, ID turning / boring

- Grooving, threading

- Live tooling enables drilling, tapping, or milling in one setup

- Secondary Machining & Additional Processes

- CNC milling for flats or slots

- Cross drilling for holes

- Tapping or reaming for precision threads

- Surface Finishing & Post-Processing

- Anodizing, electroplating, nickel plating

- Black oxide, polishing, sandblasting

- Quality Control & Inspection

- Incoming material inspection

- In-process inspection

- Final inspection with calipers, micrometers, CMM

- Packaging & Delivery

- Protective wrapping and anti-rust materials

- Custom labeling for easy identification

Applications of Custom CNC Turning Parts

Our precision CNC turning parts are widely used in:

- Automotive: shafts, bushings, connectors

- Hydraulics & Pneumatics: fittings, valve components

- Industrial Machinery: spindles, couplings, adapters

- Electronics: housings, connectors

- Medical Devices: high-precision components

Supports both low-volume prototypes and high-volume production.

Key Benefits of Precision CNC Turning

- Tight tolerances (±0.01 mm or better)

- Excellent repeatability

- Wide material compatibility

- Cost-effective for medium to large batches

- Reduced lead time through automation

FAQ: CNC Turning Parts Supplier

Q1: What tolerances can CNC turning achieve?

- Typically ±0.01 mm, depending on material and geometry.

Q2: Is CNC turning suitable for small batch orders?

- Yes, ideal for prototyping and production runs.

Q3: What materials are best for CNC turning?

- Aluminum, stainless steel, carbon steel, brass.

Q4: Can CNC turning handle complex designs?

- Yes, live tooling and secondary machining allow complex features.

Q5: How do I choose OEM vs ODM CNC turning service?

- OEM: you have drawings. ODM: need design support or optimization.

Q6: Can provide material report , inspection report ?

- Both can supply

Applications of Custom CNC Turning Parts (With Real Cases)

Our precision CNC turning parts are widely used across industries, and we have successfully delivered projects for clients with strict quality and precision requirements:

-

Automotive: Shafts, bushings, and connectors,sleeve.

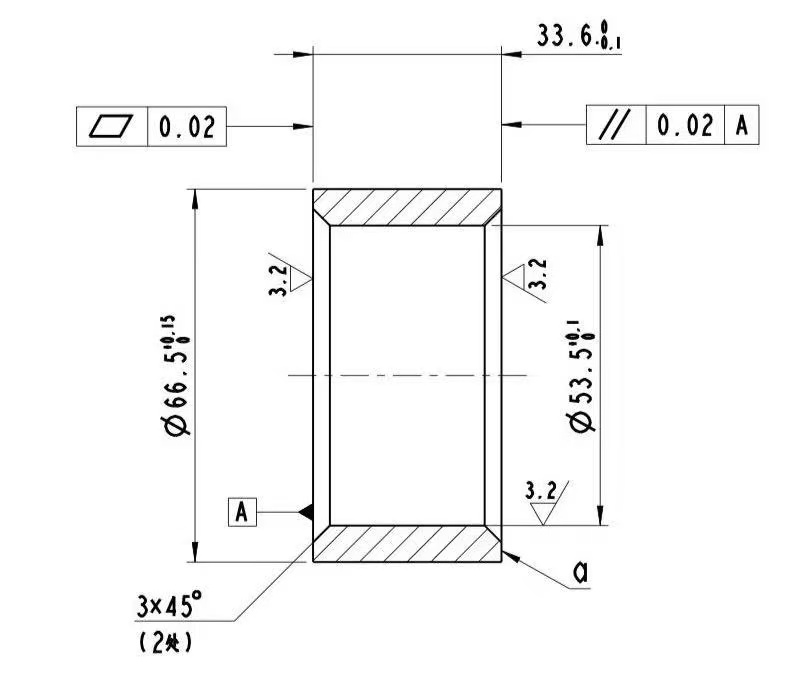

Case: We customized precision sleeve for an automotive client, achieving Parallelism demand ±0.01 mm tolerance for high-speed transmission systems. The parts passed rigorous durability tests and were integrated seamlessly into the client’s assembly line.

At the beginning, we used collets with liners for production, but we were unable to achieve the required parallelism. Later, we improved the process by leaving material allowance on the collet during machining, allowing the part to be  processed on two surfaces in a single setup. This ensured symmetrical length and achieved a precision of 0.02 mm.

processed on two surfaces in a single setup. This ensured symmetrical length and achieved a precision of 0.02 mm.

-

Hydraulics & Pneumatics: Fittings, valve components.

Case: For a hydraulic valve manufacturer, we produced stainless steel fittings with NPTF threading based on drawing .

Conclusion: Choose Our CNC Turning Manufacturing Services

With over 10 years of experience, our in-house CNC turning factory delivers OEM & ODM precision parts with tight tolerances, high repeatability, and strict quality control.

Whether you need rotational components for automotive, hydraulics, industrial machinery, or electronics, our custom CNC turning services provide reliable, cost-effective, and high-quality solutions.