Choosing a custom parts manufacturer is not simply about finding a factory that can machine metal. It is about finding a manufacturing partner who understands customer demand clearly ,supply the same size based on the drawing and take carefully all material detail and size detail , especially in industries where pressure, sealing, and long-term reliability matter.

We are a custom parts manufacturer specialized in pipe fittings, serving automotive applications, hydraulic systems, oil connectors, and pipeline-related components. Our work focuses on mass production of custom-designed parts , we are supply OEM/ODM cnc machinery service online.

What Does a Custom Parts Manufacturer Really Do?

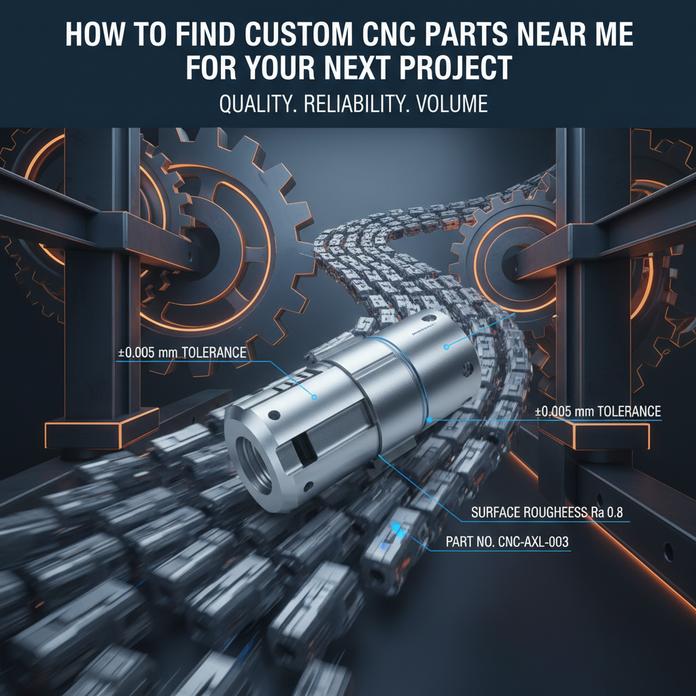

A custom parts manufacturer produces components based on drawings, specifications, and application requirements, rather than selling standard catalog products.

In pipe fitting manufacturing, “custom” means staisfy the demand of customer drawing or samples. It means:

- Custom demand thread standards

- Suitable materials for pressure and fatigue

- Customer demand heat treatment and surface finishing ,Like hardness HRC 28-33.

- Stable quality across thousands of pieces

As a custom parts manufacturer, our role is to transform engineering requirements into repeatable, production-ready components.

Custom Parts Manufacturer vs Standard Parts Supplier

Standard parts suppliers focus on inventory. A custom parts manufacturer focuses on process control.

Standard fittings are designed for general use. They work well in simple applications, but in automotive and hydraulic systems, standard parts often face limitations:

- Tolerances may not meet sealing requirements

- Thread forms may not match system standards

- Materials may not support long-term load or vibration

Custom pipe fittings are designed around actual working conditions, not assumptions.

Our Product Focus: Custom Pipe Fittings for Industrial Systems

As a custom parts manufacturer, we focus on small to medium-sized pipe fittings, rather than large structural components.

Typical part dimensions:

- Outer diameter: 6 mm to 70 mm

- Length: within 200 mm

We specialize in:

- CNC turning

- Deep-hole drilling

- Precision internal and external threading

- Grinding

- Punching

These processes are critical for hydraulic and automotive connectors, where internal structure and thread accuracy directly affect system performance.

Thread Machining Is a Core Capability, Not an Afterthought

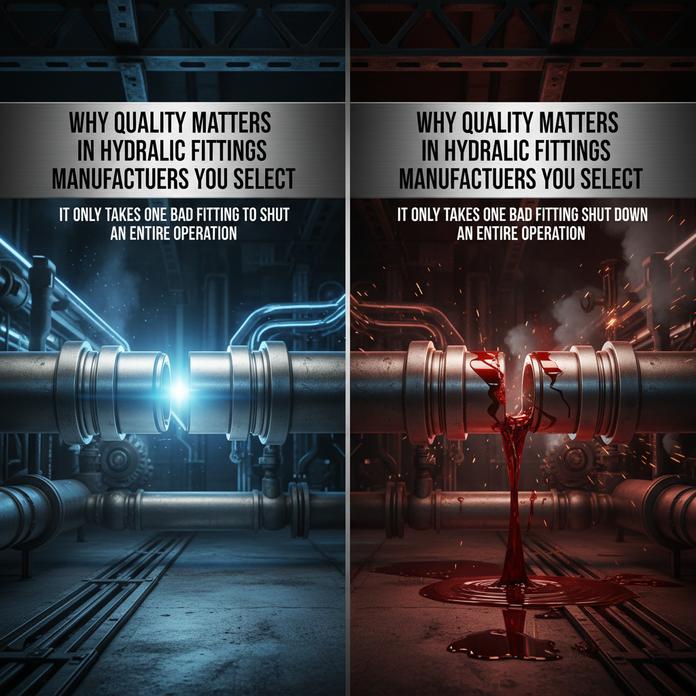

Thread quality determines whether a pipe fitting works or fails.

We have extensive experience machining:

- Metric threads (M)

- G threads

- BSP / BSPT

- NPT / NPTF

These include both British pipe threads and American thread standards, commonly used in automotive and hydraulic systems. In mass production, thread consistency is more important than single-piece accuracy. That is why thread pass rate is one of our most critical quality indicators.

Material Knowledge Is the Foundation of Custom Manufacturing

Custom manufacturing is not just about machining — it is about understanding materials.

We regularly process:

- Low carbon steel: AISI1008, AISI1010, AISI1020

- Medium carbon steel: AISI 1035,AISI 1045

- Alloy steel: 40Cr, 42CrMo

- Stainless steel: 201, 303, 304, 316, 316L

| Image | Name | Description | Surface Treament |

|---|---|---|---|

| Stainless Steel | Good machinability + High tensile strength + Corrosion resistant | Nickle plated , passivation,chrome plated,polish , clean surface. |

| Steel | Good machinability + High tensile strength + Good ductility and weldability | Zinc plating, Nickel plating, Chrome plating, Black oxide, Heat treatment, Carburized, electrophoresis, Chemical nickel, Blackening treatment, Antirust oil |

| Aluminum | High machinability + Good strength-to-weight ratio | Chrome Plating,Anodizing |

| Brass | Good machinability + Excellent electrical conductivity + Low friction + Golden appearance | Acid cleaning, Nickel plating, Chrome plating, Polishing |

Each material responds differently to machining, heat treatment, and surface finishing. Knowing these behaviors helps us avoid problems before they appear in production.

Heat Treatment: When It Works, and When It Doesn’t

In automotive fittings, increasing hardness is often required. However, not all steels can be strengthened the same way.

- Medium carbon steel can be directly heat treated

- Low carbon steel cannot achieve sufficient hardness through direct heat treatment

- Carburizing is required when surface hardness is needed on low carbon steel

Heat treatment also introduces risks:

- Dimensional deformation

- Increased machining difficulty

For this reason, we often arrange heat treatment before final machining, and use cutting tools designed for hardened materials. This approach helps maintain dimensional accuracy while keeping production stable.

Surface Treatment Selection Based on Application

Surface treatment is chosen for function, not appearance.

Common surface treatments we coordinate include:

- Zinc plating

- Zinc-nickel alloy plating

- Chemical nickel plating

- Nickel plating

- Black oxide

- Electrophoresis

- Dacromet

Located in Yuhuan, Taizhou, Zhejiang, our factory benefits from a complete local industrial supply chain. Material sourcing, heat treatment, and surface finishing can be coordinated efficiently, reducing lead time and quality risk.

Quality Control Focused on Mass Production Stability

As a custom parts manufacturer for batch production, quality control is built into the process.

Key quality priorities include:

- Thread qualification rate

- Routine in-process inspection

- Batch consistency monitoring

This approach ensures stable quality for automotive tier-2 suppliers and hydraulic fitting wholesalers, where repeatability is essential.

Why Choose a Custom Parts Manufacturer Instead of a Trading Company?

Working directly with a factory means:

- Direct communication with engineers

- Faster technical feedback

- Transparent cost structure

- Better control over quality and delivery

A trading company sells products.

A custom parts manufacturer controls production.

From Drawing to Delivery: How We Work

- Drawing and requirement review

- Material selection and process planning

- CNC turning, drilling, and threading

- Heat treatment and surface finishing coordination

- Process inspection and final quality checks

- Packaging and batch delivery

A Custom Parts Manufacturer Built for Pipe Fittings

We do not try to manufacture everything. We focus on custom pipe fittings for automotive, hydraulic, and pipeline systems, and we focus on doing them well in mass production.

That is what a professional custom parts manufacturer is meant to be.