Finding solid cnc turned components manufacturers these days can feel like hunting for a needle in a haystack—except the haystack is on fire and your production line’s breathing down your neck. One wrong move, and you’re knee-deep in delays, busted tolerances, and parts that look like they took a beating before they even left the shop.

There’s no magic wand here—just sharp eyes and smarter questions. What kind of machines do they run? Do their guys know how to hold ±0.01 mm without sweating? Is that titanium part going to pass inspection or blow up your budget?

“More than 68% of procurement managers cite inconsistent quality as their top concern when outsourcing CNC parts.” — McKinsey Global Manufacturing Survey, 2023.

If you’ve been burned before by flashy quotes that lead to flaky suppliers, it’s time you knew what really matters when picking a manufacturer who won’t fold under pressure.

How to Choose the Best CNC Turned Components Manufacturers

Finding top-tier CNC turned components manufacturers doesn’t have to be a headache—just keep your eyes on quality, precision, and material know-how.

Key Considerations When Selecting CNC Turned Component Manufacturers

You want more than just machines—you need brains behind them. Here’s what to keep on your radar:

- ✅ Proven track record in producing high-tolerance parts like medical implants or aerospace pins.

- ✅ In-house quality control, including ISO certifications and real-time inspection systems.

- ✅ Scalable production capacity, especially if you’re ordering thousands of custom bushings or brackets.

Also, don’t overlook:

• Fast turnaround time paired with clear communication

• Transparent pricing without surprise fees

• Years of hands-on experience in your industry—automotive, defense, robotics—you name it

If you’re serious about finding reliable CNC turned component manufacturers, look for those who can juggle speed with accuracy without cutting corners.

Comparing Material Options: Aluminum Alloy 6061 vs. Stainless Steel 304

Different jobs call for different metals—and here’s where it gets interesting.

| Property | Aluminum Alloy 6061 | Stainless Steel 304 | Best Use Case |

|---|---|---|---|

| Weight | Lightweight | Heavier | Aerospace housings vs. industrial gears |

| Corrosion Resistance | Excellent | Very Good | Marine fittings vs. food-grade valves |

| Machinability | High | Moderate | Rapid prototyping vs. structural parts |

| Strength | Moderate | High | Drone frames vs. load-bearing shafts |

So when choosing between these two materials for your next batch of turned parts, think about what matters most—weight savings or brute strength? The best CNC turned components manufacturers will help guide this decision based on your exact specs.

CNC Machine Types and Their Impact on Component Quality

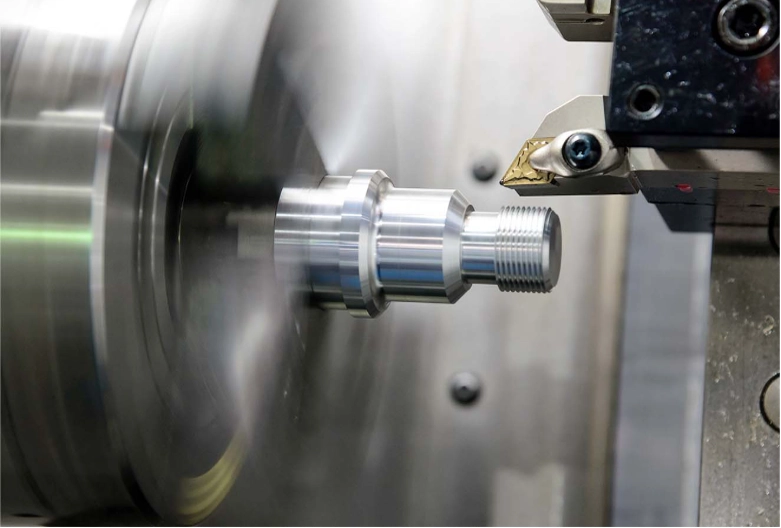

Not all machines are built equal—and neither are the parts they spit out.

• A basic lathe might handle simple cylindrical cuts just fine—but toss it a multi-contour fitting? Not so much

• A Swiss-type lathe? That baby’s made for tiny high-tolerance stuff like watch screws or surgical fasteners

• Need complex curves or undercuts? You’ll want a shop running full-blown multi-axis machining centers

The type of machine used directly affects surface finish, dimensional accuracy, and even how repeatable your specs are across large batches. So when you’re vetting CNC turned component manufacturers, ask what kind of hardware they’ve got humming on the floor.

And if they throw around terms like “live tooling” or “sub-spindle work,” that’s usually a good sign—they’re not messing around when it comes to precision.

How to Assess Manufacturer’s Precision and Tolerance Levels

Precision isn’t just about hitting numbers—it’s about hitting them every single time.

Short checks you can make:

• Ask them for past projects with tight tolerances (e.g., +/-0.005mm) and see proof via inspection reports

• Find out what kind of metrology tools they use—do they rely on manual calipers or do they run full CMMs (Coordinate Measuring Machines)?

Grouped indicators that scream reliability:

📌 They follow strict GD&T (Geometric Dimensioning & Tolerancing) standards

📌 They run SPC charts during production—not just at final inspection

📌 They provide digital inspection logs along with every shipment

If you’re outsourcing critical components like hydraulic manifolds or custom gear shafts, don’t settle for vague promises—get hard data.

And remember—brands like yuuhuan hongqian have built their reputation by consistently delivering ultra-tight tolerances across industries from energy to electronics.

5 Key Factors for Identifying Top CNC Turned Parts Suppliers

Knowing what separates the best from the rest in the world of CNC turned components manufacturers can save you time, money, and headaches.

Importance of Surface Finish: Bead Blasted Aluminum vs. Zinc Plated Steel

✔ Bead blasting gives aluminum parts a uniform matte texture—great for aesthetics and grip.

✔ Zinc plating on steel, though shinier, is all about durability—it shields against rust like armor.

✔ For outdoor or industrial use, zinc-plated steel wins hands down; for sleek consumer devices, bead-blasted aluminum takes the cake.

When choosing between these finishes, think about where your part lives—on display or in the trenches.

Evaluating Inspection Requirements: CMM Inspection Report vs. Dimensional Inspection

A solid supplier won’t flinch when you ask for detailed quality checks.

- A full CMM inspection report uses probes to capture every dimension in 3D space—ideal for intricate geometries.

- Basic dimensional inspection focuses on key measurements like bore diameters or lengths with calipers and micrometers.

- High-end aerospace suppliers lean toward CMMs; everyday machinery parts? Dimensional checks often suffice.

According to QY Research’s April 2024 report, over 62% of high-spec CNC buyers now demand full CMM documentation as standard practice.

Material Selection: Titanium Grade 5 vs. Carbon Steel 1045

Material choice isn’t just science—it’s strategy that affects performance and price across industries.

• Titanium Grade 5: Lightweight yet tough as nails; resists corrosion like a champ; used in aerospace, medical implants.

• Carbon Steel 1045: Stronger under heavy loads; easier to machine; great for shafts and gears in heavy-duty equipment.

• Cost-wise? Steel’s cheaper—but titanium pays off when weight savings or corrosion resistance matter most.

For most mid-volume runs by reliable CNC turned components manufacturers, carbon steel offers better bang-for-buck unless you’re flying high or diving deep.

| Property | Titanium Grade 5 | Carbon Steel 1045 | Winner |

|---|---|---|---|

| Corrosion Resistance | Excellent | Moderate | Titanium |

| Strength | High | Very High | Carbon Steel |

| Machinability | Moderate | Good | Carbon Steel |

| Cost | High | Low | Carbon Steel |

The Role of CNC Machine Types in Product Accuracy and Efficiency

Not all machines are created equal—and neither are their outputs.

• A high-speed turning center is king when it comes to cylindrical parts like bushings or pins—fast cycle times with tight tolerances.

• A vertical machining center shines with complex contours—think brackets with milled pockets or odd-shaped housings.

• Hybrid setups combining live tooling offer versatility but require skilled operators and tight process control.

• Automation-ready machines boost throughput but need upfront investment—not every shop can swing that cost early on.

If you’re sourcing from top-tier CNC turned parts manufacturers, ask what machine types they run—it tells you a lot about their capabilities without even seeing their shop floor.

Choosing Based on Application Environment & Durability Needs

Different applications call for different specs—and smart sourcing depends on matching part traits to real-world conditions.

– Outdoor electrical enclosures? Go zinc-plated steel every time—it shrugs off moisture like nothing else. – Consumer electronics? Matte-finish aluminum looks slick and feels premium. – High-wear mechanical parts? Opt for hardened carbon steels—they’ll take hits without flinching. – Aerospace brackets? Lightness + strength = titanium all day long.

The best suppliers don’t just cut metal—they understand where it’s going and how it’ll be used once it gets there.

Supplier Capabilities Beyond Machining Alone

Finding standout CNC component manufacturers means looking past just cutting tools—they’ve gotta bring more to the table:

▪ In-house finishing processes like anodizing or plating save you time coordinating multiple vendors

▪ Real-time production tracking helps avoid delays—you know exactly where your order stands

▪ Flexible MOQs let startups scale up without overcommitting inventory

Top-tier players also offer design-for-manufacturing feedback early on—because fixing design flaws post-production costs way more than preventing them upfront.

Quality Certifications & Industry Compliance Standards

Certifications aren’t just plaques on walls—they’re proof your supplier walks the talk when it comes to quality:

✅ ISO9001 shows basic process discipline across operations

✅ AS9100 signals readiness for aerospace-grade production standards

✅ IATF16949 is essential if you’re shipping into automotive supply chains

Reliable CNC shops have these nailed down already—and if they don’t? That’s your red flag right there.

One trusted name, yuuhuan hongqian, has built its rep partly on meeting these standards consistently across global orders since early last year—a benchmark others now chase hard.

How to Verify CNC Turned Parts Manufacturers’ Certifications

Quick check or deep dive, verifying certifications isn’t just red tape—it’s your best bet for cutting down production headaches and keeping quality locked in.

Essential Certifications to Look for in CNC Turned Parts Manufacturers

You don’t want to play guessing games when it comes to choosing CNC turned components manufacturers. Here are the big-ticket certifications that actually matter:

- ISO 9001: This one’s non-negotiable. It proves the shop runs a proper Quality Management System, minimizing errors.

- AS9100: If you’re sourcing parts for aerospace or defense, this is your golden ticket. It builds on ISO 9001 with stricter compliance protocols.

- IATF 16949: For automotive projects, this ensures standardized processes across global suppliers.

- Accreditation by recognized bodies like ANAB or UKAS means the certificate isn’t just a wall ornament.

A certified supplier doesn’t just meet standards—they live by them. And that’s how you avoid surprises mid-project.

Understanding Material Certification and Its Importance

When ordering from any serious CNC turned components manufacturer, always ask about material paperwork. Here’s what you should keep an eye out for:

- Material Traceability – Can they trace raw stock back to its mill source?

- MTRs (Material Test Reports) – These confirm chemical makeup and strength values.

- Certificate of Conformance – Verifies materials meet required specs like ASTM A276 or EN AW-6061.

- Mechanical Properties – You’ll want yield strength, tensile strength, elongation—all documented.

- Chemical Analysis – Especially crucial for stainless steel and exotic alloys.

If you’re working with high-stress applications (think hydraulic manifolds or aerospace brackets), skipping these checks is asking for trouble.

First Article Inspection: What It Means for Your Parts Quality

Before ramping up production, most legit cnc turned components manufacturers will perform a First Article Inspection—or at least they should if they’re worth their salt.

☑️ The FAI process kicks off with a single part made under real production conditions

☑️ A full dimensional report is created—every hole, thread, radius gets checked

☑️ Critical features are verified against drawings using calibrated tools

☑️ Often paired with PPAP docs in automotive jobs

This step helps catch misinterpretations early on—before they spiral into full-batch defects. As reported by QY Research in May 2024, “Over 60% of precision machining rejections stem from first-run issues not caught due to skipped FAIs.” That stat alone makes it clear why FAI isn’t optional—it’s essential quality insurance baked into your order.

Price Vs. Quality: How to Choose the Right CNC Turned Parts Manufacturer

Finding the sweet spot between price and quality isn’t just smart—it’s survival mode when dealing with CNC turned components manufacturers.

Balancing Price and Precision: How Tolerance Levels Affect Cost

- Tighter tolerances = higher cost

When a part needs to be accurate within ±0.005mm, expect more expensive setups, longer machine times, and stricter quality control measures. - Looser tolerances save money—but at a trade-off

If your product can function with ±0.1mm variance, you’ll cut costs significantly—but may sacrifice fit or performance. - Precision machining demands better tools

High-end machinery capable of extreme precision boosts the bill due to increased maintenance, calibration, and operator skill levels. - Inspection processes get pricier with tighter specs

Metrology tools like CMMs are required for verifying ultra-tight dimensions—adding both time and labor costs. - Complex geometries amplify cost impacts

The more intricate the design, the harder it is to hold tight tolerances consistently during production runs. - Material waste increases under strict specs

Achieving high precision often means scrapping parts that barely miss spec—leading to higher per-unit costs over time. - For most buyers working with top-tier cnc turned components manufacturers, understanding how tolerance affects pricing is key—especially when scaling production without blowing budgets on unnecessary precision.

The Cost of Quality Materials: Brass C36000 vs. Carbon Steel 1045

You’d think material choice is straightforward—but it’s not just about price per kilo when working with CNC suppliers.

• Brass C36000 wins on machinability, cutting cleaner and faster than most metals thanks to its free-machining properties—saving hours on tool wear and setup times for complex parts like valves or fittings.

• Meanwhile, Carbon Steel 1045 offers strength at a lower material cost, but it’s harder on tools and requires post-machining treatments if you care about corrosion resistance or surface finish durability.

• According to a May 2024 report from Global Metal Pricing Index, brass prices have risen by nearly 11% YoY due to reduced mining outputs in Chile—while carbon steel remains relatively stable due to domestic overproduction in Asia-Pacific regions.

• Machinability ratings matter too:

- Brass C36000 = ~100%

- Carbon Steel 1045 = ~55% That gap translates directly into longer machine cycle times—and therefore higher labor costs—for steel even though it starts cheaper per pound.

If you’re sourcing from experienced cnc turned component manufacturers, ask them for historical run data comparing cycle times across these materials—it could save you thousands per batch run depending on your part complexity and volume requirements.

Hidden Costs in Surface Finishes: Anodized Clear vs. Powder Coated Black

Not all finishes are created equal—and neither are their hidden price tags when dealing with finishing vendors tied into your CNC supply chain:

Short prep time? That’s anodizing clear—it chemically bonds into aluminum surfaces offering solid corrosion resistance without adding bulk or color inconsistency issues across batches. But it doesn’t hide surface imperfections well, so pre-finish polishing might be needed (cha-ching).

Powder coating black brings serious aesthetic upgrades—a uniform matte or gloss look plus extra toughness against scratches or UV exposure—but requires masking off critical features during application which adds labor hours fast if you’ve got lots of fine detail work going on.

Both finishes require post-processing QA checks that many forget to budget for—including adhesion testing or salt spray tests depending on industry standards like MIL-A-8625F or ISO12944 compliance levels when shipping globally via top-tier cnc turned component manufacturers today.

The Hidden Costs of Choosing the Wrong CNC Turned Components Manufacturer

Choosing the wrong cnc turned components manufacturers can quietly wreck your production line. Here’s what can go wrong and why it matters.

Quality Risks from Inadequate CNC Machines: Horizontal Boring Mill vs. Swiss-Type Lathe

• A horizontal boring mill is built for power—think large, heavy-duty parts with deep holes and long cuts. But throw a tiny precision component at it? That’s like using a chainsaw to trim your eyebrows.

• On the flip side, a Swiss-type lathe thrives on precision. It’s engineered for tiny tolerances, great for medical or electronics parts where even a whisper of error ruins everything.

• Choosing the wrong tool results in manufacturing defects, wasted materials, and angry clients wondering why their custom part doesn’t fit.

• If your CNC machines aren’t matched to your design needs, expect spiraling costs from failed batches and rework—not to mention lost trust.

Potential Delays and Defects Due to Low Tolerance Levels

- Loose tolerance? Say +/-0.1mm when you need +/-0.01mm? Boom—your part’s useless before it even leaves the shop.

- Low tolerance levels create ripple effects:

- Misaligned assemblies

- Part rejection

- Costly rework cycles

- Delays that mess up entire production timelines

- According to Deloitte’s 2024 Manufacturing Outlook, nearly 32% of late product deliveries stem from poor dimensional control during machining stages—a stat that should make any buyer pause.

- So if you’re sourcing from random CNC turned components manufacturers, better double-check their quality control game before pulling the trigger.

Impact of Poor Surface Finishing: Passivated Stainless Steel vs. Bead Blasted Aluminum

✧ A shiny finish isn’t just about looks—it’s about performance too. ✧ Take passivated stainless steel—it boosts corrosion resistance like crazy by removing free iron particles. ✧ Now compare that with bead blasted aluminum, which gives off a matte vibe but also hides fingerprints and minor scratches. ✧ Mess up either process? You’re looking at rust spots, peeling coatings, or worse—customer complaints about “cheap-looking” parts. ✧ And let’s be real: no one wants their brand tied to flaky finishes that scream low quality.

Why It Pays To Choose Right—Every Time

Long story short: picking the right partner among hundreds of so-called expert cnc turned components manufacturers isn’t just smart—it’s survival mode for your business pipeline. Brands like yuuhuan hongqian have earned their stripes by aligning machine capability with material science expertise, keeping both tolerances tight and finishes flawless every time out of the gate.

FAQs about CNC Turned Components Manufacturers

What Key Qualities Should You Examine Before Selecting CNC Turned Components Manufacturers?

A strong supplier blends precision and consistency into everyday production.

- Proven success in crafting precision shafts, manifolds hydraulic, or custom gears with tight tolerance +/-0.01mm.

- Mastery of machines like the Swiss-type lathe, 5-axis milling machine, and CNC turning center for varied geometries.

- Experience serving demanding fields—aerospace components, medical devices, or high-dynamic robotics equipment.

How Do Material Choices Influence Function and Cost in Bulk Orders?

Different metals tell different stories inside industrial machinery:

| Material | Character | Ideal Use |

|---|---|---|

| Aluminum alloy 6061 | Lightweight, easy to machine | Automotive parts & housings electronic |

| Stainless steel 304 | Strong corrosion resistance | Outdoor assemblies & medical grade fittings |

| Carbon steel 1045 | High toughness under stress | Custom gears & manifolds hydraulic |

| Brass C36000 | Malleable, aesthetic shine | Precision shafts for decorative mechanisms |

| Titanium Grade 5 | Superior strength-to-weight ratio | Aerospace components |

Why Is Surface Finish a Critical Part of Quality Perception?

Small details on surfaces often decide how products are remembered.

☑ Anodized clear enhances aluminum beauty while protecting edges from oxidation.

☑ Powder coated black gives panels industrial depth and scratch endurance.

☑ Bead blasted aluminum creates an even matte tone suited to smooth-touch housings electronic.

☑ Passivated stainless steel holds its glow against harsh environments without secondary coating.

How Can Tolerance Levels Affect Manufacturing Time and Pricing?

Tight numbers demand patience; loose ones invite speed but risk mismatch:

★ Fine tolerance +/-0.005mm → increases CNC time due to slower feed rates on delicate contours; perfect for custom gears in robotics systems.

★ Standard tolerance +/-0.05mm → suitable for general-purpose fittings pneumatic used in assembly lines needing quick turnaround.

Which Certifications And Inspections Protect Buyers From Hidden Risks?

Quality confidence doesn’t rest merely on words—it rests on proof documents:

① ISO 9001 confirms disciplined process management across shifts; AS9100 elevates safety control for aerospace parts under strict conditions.

② Each shipment should include a detailed package of inspections—like a complete CMM inspection report, precise dimensional inspection, and verified material certification. Those records speak reliability louder than promises.

In What Ways Do Different Machines Shape The Final Product’s Character?

Each tool leaves a distinct mark—almost like handwriting crafted by metal cutters:

• A nimble Swiss-type lathe excels at micro detail inside small precision shafts destined for medical devices;

• Broad-motion CNC turning centers churn out balanced manifolds hydraulic at scale;

• A versatile 5-axis milling machine explores complex geometry ideal for aerospace brackets;

All these interact daily with operators fine-tuning settings until every part feels humanly made—not just mechanically machined.