In the world of piping and fluid transfer systems, precision and reliability are paramount. Among the many connection technologies available today, stainless steel twin ferrule compression fittings stand out for their strength, safety, and performance.

These stainless compression fittings deliver secure, leak-proof joints across industries that demand exceptional durability and pressure resistance — from oil and gas to instrumentation and chemical processing.

This guide explores how twin ferrule fittings work, their advantages, applications, and why they’ve become the trusted standard for professionals who rely on stainless steel pipes and fittings.

What Are Twin Ferrule Compression Fittings?

Twin ferrule compression fittings — also known as double ferrule fittings — are mechanical connectors designed to join tubes or pipes without welding.

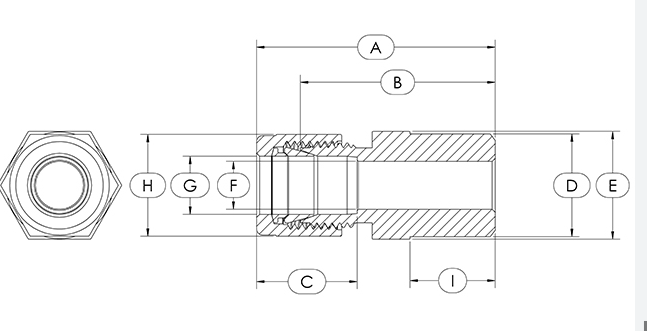

They consist of two ferrules (rings) that compress around the tube to form a robust, vibration-resistant seal.

Body: The central part of the fitting that houses the tube connection.

Compression Nut: Tightens onto the fitting body to compress the ferrules.

Front Ferrule: Creates the initial seal by gripping and swaging onto the tube.

Rear Ferrule: Provides additional support and holds the tube firmly in place.

The twin ferrule mechanism operates on a dual-compression principle to achieve a tight, leak-proof seal:

Insertion: The tube is inserted fully into the fitting body.

Compression: As the nut is tightened, the front ferrule compresses against the tube surface, forming a strong seal.

Dual Action: Simultaneously, the rear ferrule grips the tube and holds it in alignment, ensuring stability and resistance to vibration or pressure fluctuations.

This dual ferrule design is what distinguishes these fittings from single ferrule or flare types, delivering superior sealing integrity.

1-Leak-Proof Performance

The double ferrule design ensures consistent, repeatable sealing even under extreme pressure or temperature variations — a key benefit for stainless steel compression fittings used in critical applications.

2-High Pressure and Vibration Resistance

Twin ferrule fittings can handle pressures up to several thousand psi, making them ideal for instrumentation lines, hydraulic systems, and bulkhead plumbing fittings in demanding environments.

3-Corrosion and Heat Resistance

Manufactured from high-grade stainless steel, these fittings resist corrosion, oxidation, and thermal stress — extending the life of stainless steel pipes and fittings in harsh industrial conditions.

4-Easy Installation and Maintenance

They require no special tools or welding. Assemblies can be easily disassembled and reassembled without losing sealing performance.

5-Versatility

Suitable for stainless steel, copper, or alloy tubes — ideal across multiple industries such as chemical processing, oil and gas, and marine systems.

Thanks to their reliability and durability, stainless compression fittings are used across diverse industries:

Oil & Gas: High-pressure pipelines and offshore platforms.

Chemical Processing: Secure fluid transfer of corrosive or hazardous materials.

Aerospace & Automotive: Precision control systems requiring vibration resistance.

Marine: Corrosion-resistant connections in saltwater environments.

Instrumentation & Control: Leak-proof connections for pressure, flow, and temperature instruments.

Bulkhead Plumbing Systems: Reliable connections through walls or panels using bulkhead plumbing fittings.

To ensure the best performance and longevity:

Preparation: Always clean the tube ends and fitting body to remove dirt or debris.

Proper Tightening: Tighten the nut evenly — over-tightening can damage ferrules or the tube.

Regular Inspection: Check fittings periodically for corrosion or leaks and replace worn components.

Compatibility Check: Ensure the fitting material and size match the stainless steel pipes and fittings in your system.

In critical systems where leakage or failure is not an option, stainless steel twin ferrule compression fittings provide unmatched reliability and peace of mind.

Their dual-ferrule design, combined with stainless steel’s strength and corrosion resistance, ensures long-term performance even under the most demanding operating conditions.

Whether you’re designing a high-pressure chemical line, a marine fuel system, or a precision instrument panel, these fittings represent engineering excellence and practical utility — a smart choice for professionals who value safety, precision, and durability.

Choosing the right fittings is essential to the success of any piping or instrumentation system.

By understanding how twin ferrule compression fittings work — and applying best practices for installation and maintenance — you can ensure reliable, leak-free operation for years to come.

If you are sourcing stainless steel compression fittings, bulkhead plumbing fittings, or stainless steel pipes and fittings, make sure to select quality-assured products that meet your pressure, temperature, and material compatibility requirements.