pipe fitting introdction In industrial manufacturing, the reliability of pipe fittings and hex socket plugs can make or break a system’s performance. Yuhuan Hongqian, based in Taizhou, China, specializes in providing high-quality, custom solutions for both iron and stainless steel products. Our clients range from hydraulic system integrators to OEM machinery manufacturers who demand precision, durability, and cost-effective production methods.

From standard fittings to complex custom components, we understand that each project requires careful attention to material selection, machining process, and surface treatment. In this article, we will take you through our company’s background, our product offerings, customization workflow, a detailed industrial case study, and answers to frequently asked questions.

2. Company History and Expertise

Yuhuan hongqian is located in yuhuan ,zhejiang provice , we are a small factory focus on supply different type pipe fitting for local factories , trade companies and oversea customer. Our expertise centers on custom pipe fittings and hex socket plugs, we are familiar with different type steel fittings and brass fittings ,ss fittings etc.

- Experience with iron and stainless steel materials ,some times produce for brass , aluminum for old customer

- Precision machining capabilities suitable for high-pressure and tight-tolerance (0.02mm) produce by cnc lathe machine.

- Reliable quality control through dimensional inspection, pressure testing, and surface checks

- Collaborative engineering support for client-specific designs

Our industrial philosophy is simple: precision, quality, and reliability. Every component we produce is backed by decades of combined experience in engineering and manufacturing.

3. Product Overview

3.1 Custom Pipe Fittings

Our pipe fittings include:

- Tees, elbows, reducers, couplings, and flanges

- Material choices: iron (carbon steel) and stainless steel

- Applications: hydraulic systems, chemical processing, oil & gas pipelines, and OEM machinery

Why choose custom fittings? Standard parts may not fit every system’s specifications. Our custom solutions allow for:

- Precise dimensions and threading

- Tailored pressure ratings

- Optimized surface finishes for corrosion resistance

- Special tolerances for industrial safety

3.2 Hex Socket Plugs

Hex socket plugs are critical for sealing, assembly, and maintenance of industrial systems. We provide:

- Standard and custom sizes

- Material options: iron and corrosion-resistant stainless steel

- Applications: pipeline sealing, high-pressure systems, and industrial machinery

Advantages include:

- Precision fit ensuring leak-free connections

- Durability in high-pressure or corrosive environments

- Long-term reliability, reducing maintenance costs

4. Customization Process

Our workflow ensures each component meets client specifications, from initial inquiry to delivery:

| Step | Description |

|---|---|

| 1. Enquiry | Customer send drawing to us , we check the technical drawing and confirm if we could satisfy the demand. |

| 2. Material study | We will switch from overseas to domestic material grade, then ask for the quantity. |

| 3. Quantity | Based on the quantity and drawing , we will give the best way to choose blank . Economy design is more easy to cath order from customers. |

| 4. Approved price | Customer accept price , for custom pipe fitting , must place a sample order for test customer quality demand , customer also want to test pipe fitting manufacuturer production power . |

| 5. Quality Inspection | Material inspection ,Dimensional checks, pressure testing, surface inspection, approve the sample order |

| 6.batch production | After approve the sample order , then customer will finally place small batch order , factory and customer will start big cooperation then quality is keep steady and good . |

This step-by-step process ensures customized, high-quality industrial components suitable for demanding applications.

5. Practical Case Study: Hex Socket Plug Production

Let’s look at a real-world example illustrating how we approach industrial decision-making.

Project Details:

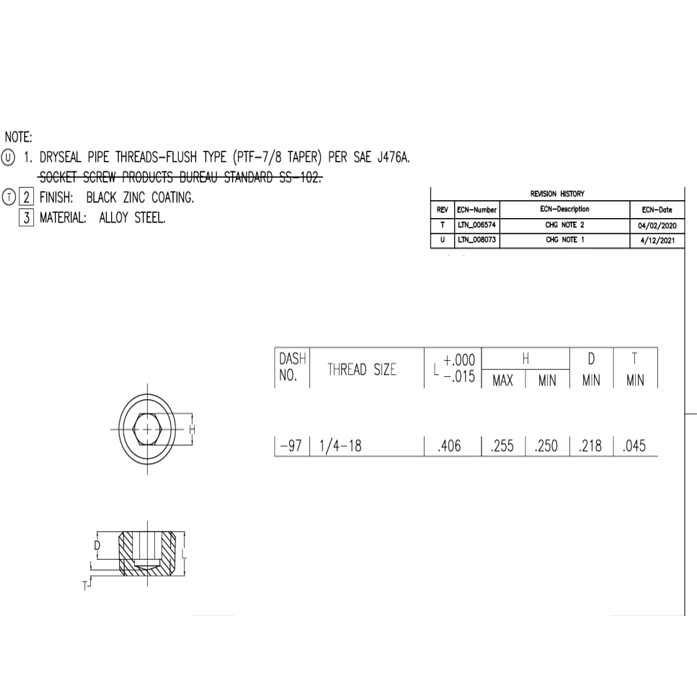

- Product: Hex socket plug

- Drawing Specifications: Inner hex 0.25 inch, small size

- Quantity: 5,000 pieces

- Thread: PTF (tapered thread requiring tight seal)

Industrial Challenge:

- Based on drawing and size, the plug would ideally be produced using cold heading (cold forging). Cold heading ensures strength and excellent surface finish.

- However, the order quantity (5,000 pieces) was too low to make cold heading cost-effective. Additionally, the small internal hex made cold heading difficult to guarantee precision.

Decision-Making:

- Abandon Cold Heading: For this small batch, cold heading is not economical and may risk quality.

- Optimal Production Method:

- Punching the blank: Start with drilled holes in the raw material.

- Forming the hex socket: Use a press to stamp the internal hex shape accurately.

- Threading Consideration:

- PTF threads are tapered and require precise hard sealing.

- Rolling threads is the most economical and practical option for this batch.

- Requires experienced technicians to ensure the taper and sealing meet industrial standards.

Outcome:

- Produced 5,000 pieces with accurate internal hex and fully sealed PTF threads.

- Maintained tight tolerances, leak-free assembly, and minimized cost.

- Delivered on time to the client in Taizhou, China, ready for industrial integration.

| Parameter | Cold Heading | Punch + Press + Roll |

|---|---|---|

| Batch Size | Not cost-effective | Economical for 5,000 pcs |

| Hex Accuracy | Hard to guarantee | High precision |

| Thread Method | Integrated | Rolling threads (experienced operators required) |

| Cost | High | Optimal |

| Time | Longer setup | Faster for small batch |

This case illustrates how industrial expertise guides process selection, balancing cost, precision, and material properties.

6. Frequently Asked Questions (FAQ)

Q1: Can Yuhuan Hongqian handle small-batch custom orders?

Yes, we specialize in batches as small as a few thousand pieces while maintaining 0.02MM precision.

Q2: How long does it take to produce custom pipe fittings or hex socket plugs?

Production typically ranges from 2–6 weeks depending on complexity, materials, and batch size.

Q3: Which materials are best for corrosive environments?

Stainless steel (304 or 316) is recommended, with Passivation or chrome plating surface treatments available for extreme conditions.

Q4: Do you provide technical support for installation?

Yes, our engineers guide clients on proper installation and sealing to ensure long-term reliability.

Q5: How do you ensure quality in small batches?

Every batch undergoes dimensional inspection, pressure testing, and surface finish checks, supervised by experienced technicians.

Q6: Can you manufacture tapered threads like PTF reliably?

Absolutely. We have technicians with extensive experience in rolling and sealing tapered threads to meet industrial requirements.

We are familar with different type thread include metric , UNF , UNEF , BSPT ,BSPP, NPT,NPTF etc.

7. Conclusion

Yuhuan Hongqian, based in Taizhou, China, provides industrial clients with custom pipe fittings and hex socket plugs designed for precision, reliability, and cost efficiency. From material selection to process optimization, and even small-batch production, we guide each project through a careful, industrial-grade workflow.

Whether your application requires iron or stainless steel, cold heading or punching, or tapered threaded sealing, our team ensures your components are ready for industrial integration.

Contact us today to discuss your next custom project and see how our Taizhou-based facility can deliver precision and reliability tailored to your needs.