Introduction: Why Choosing the Right Stainless Steel Factory Matters

When sourcing or stainless steel NPT pipe fittings, many buyers focus only on price. However, experienced procurement managers know that the factory’s material specialization matters far more than a few cents per part.

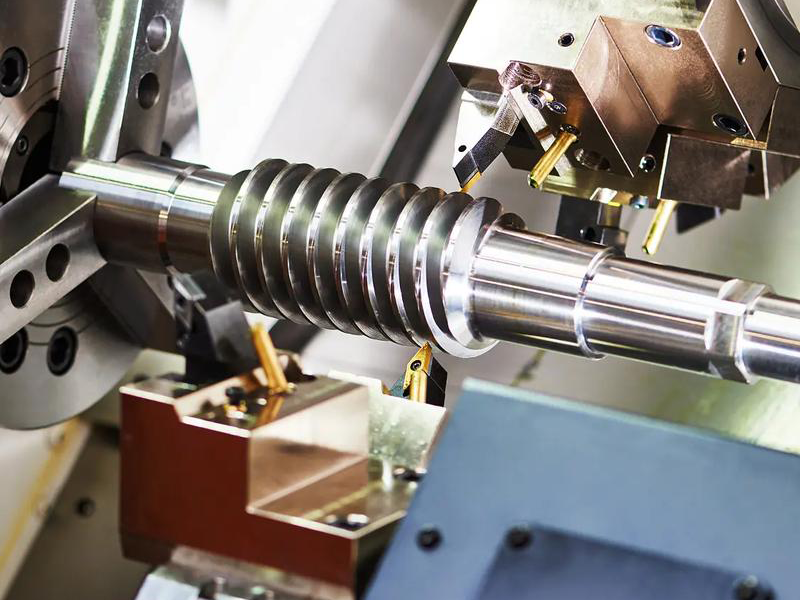

Not every CNC machining factory can truly handle stainless steel—especially 304 stainless steel pipe fittings and 316 stainless steel threaded pipe fittings. These materials require different tooling, cutting strategies, cost estimation methods, and operator experience compared with aluminum or brass.

If you choose the wrong supplier, the risks include:

- Unstable dimensions

- Poor thread quality

- Unexpected price increases

- Delayed delivery

- High rejection rates

This guide explains how to choose a reliable 316 stainless steel pipe fitting factory in China, and what technical factors really separate professional stainless steel manufacturers from general CNC workshops.

Why Stainless Steel Pipe Fittings Must Be Made by Stainless Steel Specialists

Many buyers assume that any CNC factory can machine stainless steel. In reality, this is not true.

Stainless Steel vs Aluminum & Brass: A Technical Reality

A professional stainless steel factory can usually produce aluminum and brass parts.

But aluminum or brass factories often cannot reliably machine stainless steel.

Here’s why:

1. Cutting Tool Wear Is Completely Different

| Material | Tool Life | Typical Spindle Speed | Tool Replacement |

|---|---|---|---|

| Aluminum | 1–3 days per insert | High | Rare |

| Brass | 1–3 days per insert | High | Rare |

| 304 Stainless Steel | 2–3 hours per insert | Medium | Frequent |

| 316 Stainless Steel | ~1 hour per insert | Lower | Very frequent |

Stainless steel—especially 316—has:

- Higher toughness

- Strong work-hardening

- Poor thermal conductivity

This causes rapid tool wear and requires constant insert replacement.

Factories optimized for aluminum or brass usually lack:

- Proper tooling inventory

- Stable cutting parameters

- Cost models for stainless steel

As a result, they struggle with quality and delivery.

2. Real Market Evidence: Aluminum & Brass Factories Outsource to Stainless Steel Specialists

From our customer data, 20%–30% of new clients originally come from aluminum or brass CNC factories.

These workshops eventually outsource their stainless steel orders because:

- Scrap rate becomes too high

- Thread accuracy cannot be controlled

- Tooling cost destroys margins

This is real-world proof that stainless steel machining is a different technical discipline.

3. Accurate Cost Estimation Depends on Stainless Steel Experience

Professional stainless steel pipe and fittings suppliers understand the behavior of:

- 201

- 304

- 316

- 316L

- 303

This allows accurate quotation based on:

- Tool consumption

- Cycle time

- Material removal rate

- Threading difficulty

Non-specialized factories often:

- Quote too low → raise prices later

- Quote too high → lose competitiveness

Both situations disrupt buyer budgets.

4. Operator Skill Level Is Critical

Because stainless steel inserts fail frequently, operators must:

- Detect tool wear early

- Adjust offsets precisely

- Maintain thread consistency

- Prevent work-hardening damage

Without experienced technicians, stainless parts usually suffer from:

- Oval threads

- Burrs

- Surface tearing

- Dimensional drift

And unlike aluminum, stainless steel parts are extremely difficult to rework once damaged.

Delivery Reliability Comes From Technical Maturity

Lead time failures rarely come from machines—they come from inexperience.

A mature stainless steel factory can:

- Predict tooling consumption

- Schedule insert changes

- Balance roughing and finishing cycles

- Maintain stable production rhythm

This is how professional suppliers guarantee delivery even on custom projects.

About Yuhuan Hongqian Machinery Co., Ltd

We specialize in CNC machined stainless steel and carbon steel pipe fittings with:

- 80 CNC lathe machines

- Dimensional tolerance up to ±0.02 mm

- Full material test reports

- Complete dimension inspection reports

Our production focuses on:

- 316 stainless steel pipe fittings

- 304 stainless steel pipe fittings

- stainless steel NPT pipe fittings

- Custom CNC threaded fittings

We serve global buyers looking for reliable stainless steel pipe and fittings suppliers with OEM capability.

Minimum order quantity (MOQ): 2000 pcs

Key Capabilities for Stainless Steel Threaded Pipe Fittings

Materials

- 201 / 303 / 304 / 316 / 316L stainless steel

Threads Supported (Simply introduce )

- NPT/NPT

- BSP / BSPT

- Metric

- UNF / UNEF

We have more thread experience for thread , whatever which thread you want to produce , just send me the drawing will give you reply .

Processes

- CNC turning

- Precision threading

- Drilling

- Custom machining from drawings

Quality Documentation

Each order can include:

- Material Certificate

- Dimension Report

- Tolerance Verification

CNC Machined vs General Pipe Fittings

| Feature | CNC Machined Stainless Fittings | General Cast Fittings |

|---|---|---|

| Tolerance | ±0.02 mm | ±0.3–0.5 mm |

| Thread Quality | Sharp, clean, consistent | Rough, inconsistent |

| Material Density | Solid bar stock | Possible porosity |

| Customization | High (OEM supported) | Low |

| Surface Finish | Controlled | Unstable |

For hydraulic, industrial, and precision applications, CNC machined fittings are essential.

How to Evaluate a 316 Stainless Steel Pipe Fitting Factory

Use this checklist:

✅ Does the factory specialize in stainless steel?

Ask for recent 304/316 projects—not aluminum samples.

✅ Can they explain tooling life and cutting strategy?

If they cannot describe insert change cycles, they lack stainless experience.

✅ Do they provide inspection reports?

Material + dimension reports are mandatory for serious buyers.

✅ Do they quote clearly with lead time?

Professional factories give structured quotations—not vague estimates.

✅ Do they accept OEM drawings?

Custom CNC capability is critical for real projects.

FAQ – Choosing Stainless Steel Pipe Fitting Suppliers

Q1: What is your MOQ?

A: Our minimum order quantity is 2000 pieces based on the detail drawing and samples .

Q2: Do you support custom stainless steel NPT pipe fittings?

Yes. We manufacture custom NPT threaded fittings based on drawings or samples.

Q3: Can you provide material certificates?

Yes. Material test reports and dimensional inspection reports are available for every batch.

Q4: What tolerance can you achieve?

Standard machining tolerance is ±0.02 mm by cnc lathe machine.

Q5: Why should I choose a stainless steel specialist instead of a general CNC factory?

Because stainless steel requires:

- Frequent tool replacement

- Experienced operators

- Accurate cost modeling

- Stable production control

General CNC shops optimized for aluminum or brass usually cannot maintain consistent quality on 316 stainless parts.

Final Thoughts

Choosing the right 316 stainless steel pipe fittings supplier is not about finding the cheapest quote—it’s about selecting a factory that truly understands stainless steel machining.

A professional stainless steel manufacturer offers:

- Stable thread quality

- Predictable delivery

- Accurate pricing

- Reliable inspection documentation

If you are sourcing 304 stainless steel pipe fittings, stainless steel NPT pipe fittings, or custom CNC threaded components, always prioritize technical specialization over surface-level promises.