Introduction: Why Factory Specialization Matters More Than Price

When sourcing 304 stainless steel pipe fittings from China, many buyers focus on unit price first. But experienced procurement engineers know that stainless steel machining is not just about having CNC machines—it’s about material expertise, tooling strategy, and production discipline.

A factory specialized in stainless steel can usually machine aluminum or brass.

But factories focused on aluminum or copper often struggle with stainless steel—especially threaded parts such as stainless steel NPT pipe fittings.

This article explains how to choose the right custom 304 stainless steel pipe fittings manufacturer in China, what technical factors truly matter, and how to avoid quality risks in mass production.

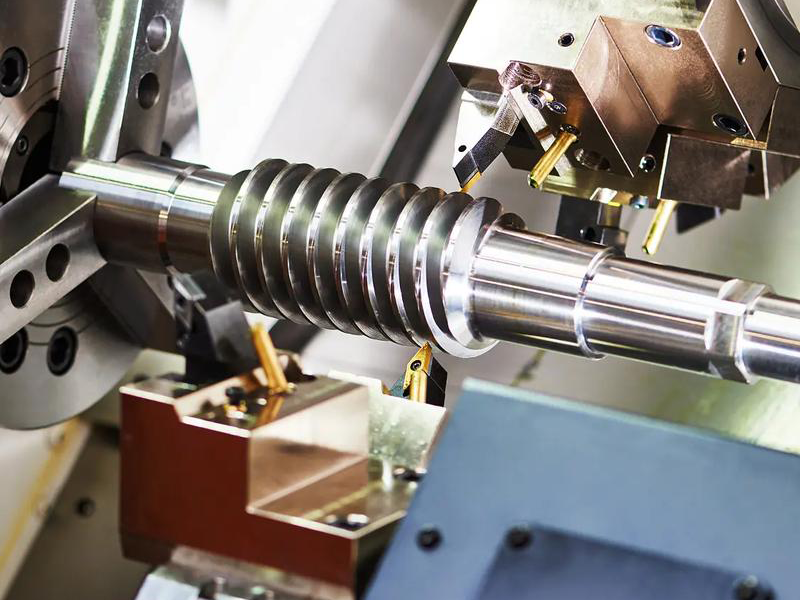

Why Stainless Steel Requires a Dedicated CNC Factory

1. Tool Wear and Cutting Speed Are Completely Different

Compared with aluminum or brass, stainless steel has:

-

Higher toughness

-

Strong work-hardening tendency

-

Poor thermal conductivity

This means cutting tools wear much faster.

In real production:

-

Aluminum / brass inserts can last 1–3 days

-

304 stainless steel inserts usually last 2–3 hours

-

316 stainless steel inserts may require replacement every hour

Without proper tooling management and cutting parameter control, thread quality quickly becomes unstable.

That’s why stainless steel machining requires:

-

Correct spindle speed selection

-

Dedicated insert grades

-

Experienced operators who can detect tool wear early

A factory without stainless steel experience may have machines—but cannot maintain consistency.

2. Real Industry Case: Aluminum & Brass Factories Outsource Stainless Orders

From our customer sources, 20–30% of new projects come from aluminum or brass CNC workshops that eventually outsource stainless steel parts.

Typical reasons:

-

High scrap rate

-

Unstable threads

-

Unexpected tooling cost

-

Delivery delays

This is real market feedback: stainless steel machining is a different technical discipline.

3. Accurate Cost Estimation Depends on Material Knowledge

Professional stainless steel pipe and fittings suppliers understand the machining behavior of:

-

201

-

303

-

304

-

316 / 316L

the differnt material but have different type ,such as bar ,tube , cold forging ,hot forging based on the drawing demand.

This allows realistic cost calculation based on:

-

Tool consumption

-

Cycle time

-

Thread complexity

-

Surface finishing requirements

Non-specialized factories often quote too low (then increase price later) or too high (lose competitiveness).

Both scenarios disrupt buyer budgets.

About Yuhuan Hongqian Machinery Co., Ltd

We are a professional CNC pipe fittings manufacturer focusing on stainless steel fittings, including:

-

Threaded pipe fittings

-

Elbows

-

Hose fittings

-

Custom CNC adapter fittings

Core Capabilities

-

80 CNC lathe machines, including gantry robots and automation

-

Over 10 years machining experience

-

Machining tolerance up to ±0.02 mm

-

Occasional aluminum and brass production for existing customers

In-house Equipment

-

CNC turning centers

-

Stamping machines

-

Tapping machines

-

Optical projectors

-

Pneumatic measuring instruments

-

Ultrasonic cleaning

Surface Treatments

-

Pickling

-

Passivation

-

Polishing

Inspection Documents

-

Material test report

-

Dimension inspection report

Product Scope

We mainly manufacture:

-

304 stainless steel pipe fittings

-

stainless steel NPT pipe fittings

-

Threaded elbows

-

Hose fittings

-

Custom CNC machined fittings (OEM)

Common materials:

- 201

-

304 / 304L

-

316 / 316L

-

303

Supported threads:

-

NPT

-

BSP / BSPT

-

Metric

-

UNF / UNEF

Applications include:

-

Aerospace systems

-

Pneumatic systems

-

HVAC installations

-

Industrial fluid pipelines

CNC Machined vs General Pipe Fittings

| Feature | CNC Machined Stainless Fittings | Cast / General Fittings |

|---|---|---|

| Tolerance | ±0.02 mm | ±0.3–0.5 mm |

| Thread Quality | Sharp & consistent | Rough |

| Material Density | Solid bar stock | Possible porosity |

| Customization | High (OEM) | Low |

| Surface Finish | Controlled | Unstable |

For aerospace, pneumatic, and HVAC systems, CNC machined fittings are essential.

Quality Control Process for 304 Stainless Steel Pipe Fittings

Quality is not checked only at the end—it is controlled throughout production.

Our standard process:

-

Incoming material inspection

-

First article inspection

-

In-process inspection

-

Final dimensional inspection

-

Thread verification with GO/NO-GO gauges

-

Optical projector measurement

-

Ultrasonic cleaning

-

Individual blister packaging

-

Pallet packing (fumigation-free export pallets)

This layered inspection system helps prevent batch defects and ensures stable thread performance.

Packaging & Export

-

Individual blister packaging

-

Carton packing

-

Palletized export (fumigation-free pallets)

Designed to protect threads during international shipping.

MOQ, Lead Time & Samples

Because we operate as a batch production factory:

-

MOQ: 2000 pcs

-

Typical lead time: around 20 days after drawing confirmation

-

Samples: available before mass production

Before bulk orders, we normally provide samples and conduct detailed quality discussions with customers. This reduces complaint risk during mass production.

How to Evaluate a 304 Stainless Steel Pipe Fittings Supplier

Use this checklist:

✅ Do they specialize in stainless steel?

Ask for recent 201/303/304/316/316 L project .

✅ Can they explain tool wear and cutting strategy?

If they cannot describe insert life, they lack stainless experience.

✅ Do they provide inspection reports?

Material + dimension reports are essential.

✅ Do they support OEM drawings?

Custom CNC capability is critical.

✅ Do they clearly state MOQ and lead time?

Professional factories always do.

FAQ – Custom Stainless Steel Pipe Fittings

Q1: What is your minimum order quantity?

A: Our MOQ is 2000 pieces.

Q2: Do you provide material certificates?

Yes. Material test reports and dimension inspection reports are available.

Q3: What tolerance can you achieve?

Standard machining tolerance is ±0.02 mm.

Q4: Do you support stainless steel NPT pipe fittings?

Yes. We manufacture custom NPT threaded fittings based on drawings or samples.

Q5: Can you produce 316 stainless steel pipe fittings?

Yes. We also machine 316 stainless steel pipe fittings for higher corrosion-resistant applications.

Q6: Do you offer surface treatments?

Yes. Pickling, passivation, and polishing are available.

Final Thoughts

Choosing the right custom 304 stainless steel pipe fittings manufacturer in China is not about finding the lowest quote—it’s about selecting a factory that truly understands stainless steel machining.

A professional supplier offers:

-

Stable thread quality

-

Predictable delivery

-

Accurate pricing

-

Complete inspection documentation

These factors directly impact your production reliability and total cost.

Call to Action

Looking for reliable 304 stainless steel pipe fittings or stainless steel NPT pipe fittings?

Send us your drawing or sample today.

MOQ: 2000 pcs | Tolerance: ±0.02 mm | Material & Dimension Reports Available

👉 Contact us now for a fast quotation and technical evaluation.