If you are sourcing 316 stainless steel pipe fittings for aerospace, pneumatic, or HVAC systems, choosing the right manufacturer is far more important than simply comparing prices.

Material grade alone does not guarantee quality. Precision CNC machining, tooling experience, inspection processes, and production management determine whether your fittings arrive on time, within tolerance, and ready for installation.

In this guide, we explain:

- What makes 316 stainless steel pipe fittings different

- How professional CNC manufacturers control quality

- What buyers should verify before placing bulk orders

- Why technical experience matters more than equipment count

- How working directly with a factory in China can reduce cost and risk

If you are looking for custom elbows, hose fittings, and stainless steel connectors, this article will help you make a confident sourcing decision.

What Are 316 Stainless Steel Pipe Fittings?

316 stainless steel pipe fittings are precision-machined components used to connect tubing, hoses, and pipelines in demanding environments.

Compared with 304 stainless steel, 316 contains molybdenum, giving it:

- Higher corrosion resistance

- Better performance in chloride environments

- Improved durability in high-humidity or chemical exposure

Typical applications include:

- Aerospace systems

- Pneumatic automation

- HVAC installations

- Fluid transfer equipment

- Industrial machinery

Common product types include:

- Straight pipe fittings

- Elbows

- Hose connectors

- Threaded adapters

- Custom CNC-turned fittings

Because these fittings often operate under pressure or vibration, machining accuracy and thread quality are critical.

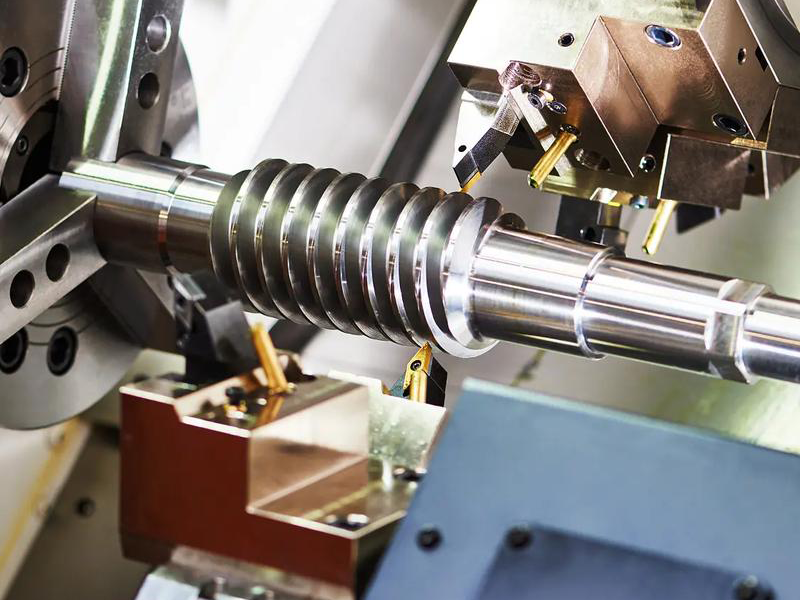

Why CNC Experience Matters More Than CNC Machines

Many buyers assume that owning CNC machines equals manufacturing capability. That is not true.

Stainless steel—especially 316—is difficult to machine. The cutting tools wear quickly, heat builds up fast, and incorrect spindle speeds can destroy surface finish or dimensional stability.

Professional factories focus on:

- Correct cutting parameters

- Tool material selection

- Chip evacuation control

- Stable fixture design

- Operator experience

Without this know-how, even modern CNC equipment cannot guarantee consistent quality. That’s why choosing an experienced manufacturer is essential.

Professional Custom Pipe Fittings Manufacturing in China

Located in Yuhuan, Yuhuan Honqian Machinery Co., Ltd. specializes in custom stainless steel pipe fittings, including elbows, hose fittings, and precision connectors.

Key manufacturing capabilities include:

CNC Production Capacity

- Over 80 CNC turning machines

- Robotic gantry loading systems

- Automated production lines

- More than 10 years of machining experience

Although the primary focus is stainless steel, aluminum and brass parts are also supported when required.

Precision & Tolerance

- Standard machining tolerance: ±0.02 mm

- Optimized spindle speeds for stainless steel

- Specialized tooling to reduce edge wear and improve surface finish

This technical control ensures stable dimensions even during mass production.

Sample & Customization Process

To give buyers confidence before placing bulk orders, we provide a structured sample and customization workflow:

- Sample Request – Submit drawings or specifications for elbows, hose fittings, or connectors. A sample is produced using the same CNC precision and material (316 stainless steel).

- Sample Verification – Buyers check thread quality, surface finish, and dimensions. Optional surface treatments like pickling, passivation, or polishing can be applied.

- Feedback & Adjustment – Any adjustments are implemented, ensuring final production meets exact requirements.

- Mass Production – After sample approval, batch production begins.

- Typical lead time: 7–10 days

- MOQ: 2,000 pcs

This workflow minimizes production risks and ensures your custom fittings meet aerospace, pneumatic, HVAC, or industrial standards.

In-House Quality Control System

Quality is built into every stage of production.

Inspection Equipment

- Optical projector

- Pneumatic measuring instruments

- Thread go/no-go gauges

- Ultrasonic cleaning machines

Inspection Process

- First Article Inspection – before mass production

- In-Process Inspection – regular patrol checks during machining

- Final Inspection – dimensional and thread verification

Threads are always verified using calibrated gauges. Material certificates and dimensional inspection reports are provided for every order.

Surface Treatment Options

Depending on application requirements:

- Pickling

- Passivation

- Polishing

- Ultrasonic cleaning

These treatments improve corrosion resistance, cleanliness, and appearance—especially important for aerospace and pneumatic systems.

Packaging & Export Standards

Finished fittings are typically packed using:

- Individual blister packaging

- Carton boxing

- Palletizing with fumigation-free export pallets

This protects threads and surfaces during international shipping.

Production Volume, MOQ & Lead Time

| Item | Standard Specification |

|---|---|

| Minimum Order Quantity | 2,000 pcs |

| Sample Availability | Yes, before mass production |

| Typical Lead Time | 7–10 days |

| Machining Tolerance | ±0.02 mm |

| Material Reports | Available |

| Dimensional Reports | Available |

| Surface Treatments | Pickling / Passivation / Polishing |

| Packaging | Blister + Export Pallet |

Samples are always produced first to approve quality and reduce bulk production complaints.

Typical Applications

- Aerospace fluid systems

- Pneumatic automation

- HVAC pipelines

- Industrial machinery

- Custom equipment assemblies

These industries demand:

- Stable tolerances

- Clean threads

- Consistent material quality

- Reliable batch repeatability

Technical CNC experience ensures these requirements are met.

How Working Directly With a Chinese Factory Benefits Buyers

- Lower unit costs

- Direct engineering communication

- Faster sample revisions

- Better control over quality standards

- Flexible customization

Most importantly, you work with the same technical team that actually machines your parts.

FAQ – Stainless Steel 316 Pipe Fittings

Q1: Can you provide material certificates?

A: Yes, mill test certificates and material reports are available.

Q2: Do you support custom drawings?

A: Yes, we strictly follow customer drawings or samples.

Q3: What is your typical MOQ?

A: Standard MOQ is 2,000 pcs, but samples are always provided before bulk orders.

Q4: How long does production take?

A: Typical lead time is 7–10 days after sample approval.

Q5: How do you control thread quality?

A: All threads are checked using go/no-go gauges during final inspection.

Q6: What industries do you mainly serve?

A: Aerospace, pneumatic automation, and HVAC systems.

Final Thoughts: Choose Experience, Not Just Equipment

316 stainless steel pipe fittings demand professional machining control. Cutting speed, tool selection, inspection discipline, and production management directly affect real-world performance.

A factory with CNC machines is common. A factory with real stainless steel machining experience is rare.

Ready to Start Your Custom 316 Stainless Steel Project?

If you’re sourcing:

- Custom elbows

- Hose fittings

- Precision stainless steel connectors

- CNC-turned pipe fittings

and want a reliable long-term manufacturing partner in China, now is the right time to connect.

👉 Send your drawings or specifications today to request samples and pricing.

Let’s discuss your project details and help you reduce cost while improving quality on your next production run.