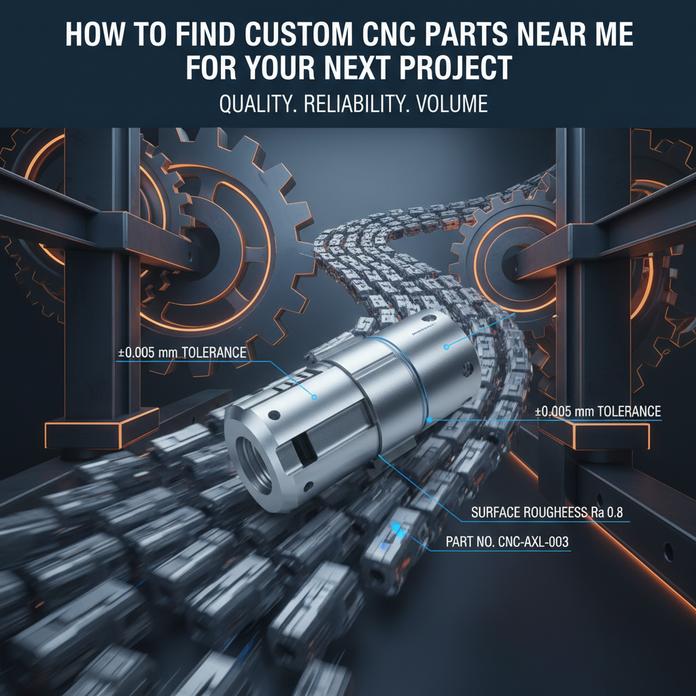

How to ensure the machining quality of CNC parts?

To ensure the machining quality of CNC parts, it is necessary to start from many aspects, the following are some key measures:

First, optimize the processing technology

Control the machining process: Every step in the CNC machining process has a crucial impact on the final quality and stability of the part. Therefore, it is necessary to develop a scientific process and clarify the operational requirements and quality standards of each step. At the same time, to ensure the accuracy and stability of machine tools, tools, fixtures and other equipment, regular maintenance and inspection of the equipment, timely replacement of worn parts.

Tool path optimization: Tool path planning is one of the key factors affecting the quality of CNC machining. Optimizing the tool path can reduce the machining time, improve the machining efficiency, but also can reduce the wear degree of the tool, extend the service life of the tool.

Select the right cutting parameters: The selection of cutting parameters directly affects the smooth progress of CNC machining process and the quality of machining. According to different materials and tools, the selection of appropriate cutting parameters (such as cutting speed, feed and depth of cutting) can effectively improve the processing efficiency, but also to ensure the quality of processing.

Control the use of coolant: Coolant can effectively reduce the cutting temperature, reduce tool wear and workpiece deformation, and have an important impact on the processing quality. Therefore, it is necessary to choose the appropriate coolant, but also pay attention to the amount of coolant and spraying method.

Second, strict quality testing

Implement strict quality inspection measures: In the process of processing, strict quality inspection measures should be implemented, including the first inspection, process monitoring and final inspection. The first piece inspection is a comprehensive inspection of the first machined part to ensure that the machining process meets the process requirements. Process monitoring is to check the parts regularly during the processing process to find and solve problems in time. Final inspection is the inspection of the last part after a batch of parts has been processed to ensure the quality of the whole batch of parts is stable.

Use advanced measuring tools: Use a variety of advanced measuring tools, such as micrometers, projectors, coordinate measuring machines, etc., to check and verify the size, shape, flatness, surface roughness and other aspects of the machined parts.

Establish quality records and documents: record key parameters, results and anomalies in the processing process, and establish quality documents and records for traceability and problem analysis.

Third, choose the right materials and tools

Material selection: To choose the material suitable for CNC machining, consider its mechanical properties, thermal stability, corrosion resistance and other factors. At the same time, according to the use and requirements of the parts, choose the appropriate material grade and heat treatment process.

Tool selection: According to the material type of the workpiece, hardness and the specific requirements of processing, choose the most suitable tool type and tool material. At the same time, it is necessary to keep the tool sharp and clean to improve the cutting efficiency and the processing quality of the parts.

Fourth, training and improving staff quality

Regular training: Regular skills training for operators to improve their processing skills and operation level.

Quality awareness: Cultivate the quality awareness of the operators, so that they realize the importance of processing quality, and can strictly abide by the quality standards and operating procedures in the work.

Fifth, continuous improvement and optimization

Problem analysis: Summarize and analyze the problems in the processing process, find out the root cause, and formulate effective improvement measures.

Continuous optimization: Continuously improve the machining quality of CNC parts through continuous improvement and optimization of machining processes, equipment and personnel skills.

To sum up, ensuring the machining quality of CNC parts needs to start from many aspects, including optimizing the processing technology, strict quality inspection, selecting the right materials and tools, training and improving the quality of employees, and continuous improvement and optimization. Only by fully considering and strictly implementing these measures can we ensure that the machining quality of CNC parts meets the needs of the market and customers.