Picture this: You’re knee-deep in a pipeline project worth millions, and the fittings you’ve waited six weeks for show up with threads that don’t match, tolerances off by a mile, and no material certs in sight. Sound familiar? Finding reliable China custom CNC parts suppliers shouldn’t feel like playing roulette in Vegas—but too often, it does.

Factories promise the moon but can’t deliver a flange on spec. Buyers need more than low prices—they need precision machining, verifiable test reports like PMI or hydrostatic testing, and delivery dates that don’t shift like desert sands. The stakes are high: one bad batch can stall an entire site.

If you’re sourcing pipe fittings at scale—from elbows to tees—you deserve better than guesswork. This guide cuts through the smoke signals so you can spot partners who walk the talk and machine to code—every time.

Essential Insights: Navigating China Custom CNC Parts Suppliers

→ CNC Machining Expertise: Look for suppliers that excel in CNC machining processes to ensure precise manufacturing, especially for critical components like Elbow 90 Degree and Tee Equal fittings.

→ Adherence to Standards: Verify that suppliers comply with international certification standards, such as ASME B16.11 and MSS SP-97, to maintain quality in applications like Power Generation Systems.

→ Robust Quality Controls: Prioritize suppliers that implement rigorous quality control practices, including Hydrostatic Testing and Dimensional Inspection, to guarantee your parts meet strict specifications.

→ Material Selection Matters: Understand the importance of material choices like Duplex Steel F51, as they significantly impact the durability and performance of custom CNC parts in various industrial applications.

→ Effective Supply Chain Management: Choose suppliers known for strong supply chain management to ensure timely delivery of components, reducing the risk of project delays in sectors such as Oil and Gas Pipelines.

Understanding the Role of China Custom CNC Parts Suppliers

This guide breaks down how china custom cnc parts suppliers shape global manufacturing through precision, materials, and supply chain strength.

The Importance of CNC Machining in Custom Parts Manufacturing

- Precision is everything. From prototyping to mass production, CNC machining delivers the consistency needed for complex geometries like Elbow 90 Degree fittings.

- Automation reduces human error and ensures repeatability across batches.

- It supports both small-scale runs and high-volume output without compromising quality.

💡 Want to cut lead time? CNC’s digital control makes it easy to tweak designs on the fly.

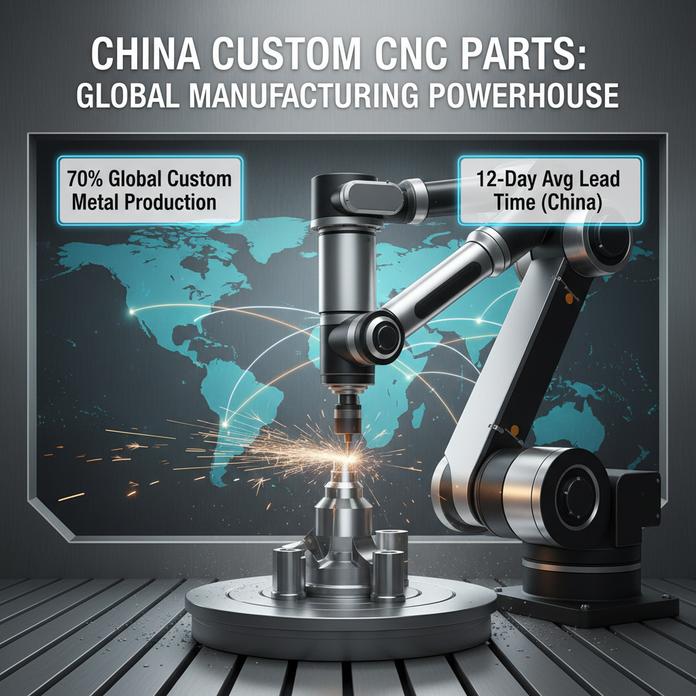

According to Deloitte’s Global Manufacturing Outlook Q2 2024, “CNC-based workflows now account for over 70% of custom metal component production globally due to their unmatched adaptability.”

Whether you’re running a local fab shop or sourcing from overseas, this tech holds it all together.

How China’s Manufacturing Industry Supports Global Supply Chains

China isn’t just about low costs anymore — it’s about scale, speed, and reliability.

- Massive production capacity allows for quick turnaround times on bulk orders.

- Strategic logistics hubs near ports reduce shipping delays dramatically.

- Government-backed industrial zones provide access to skilled labor and advanced machinery.

Here’s a quick look at how China stacks up:

| Country | Avg Lead Time (Days) | Cost Index | Export Volume (%) |

|---|---|---|---|

| China | 12 | 0.85 | 38 |

| Germany | 19 | 1.20 | 21 |

| USA | 16 | 1.35 | 18 |

| India | 14 | 0.95 | 10 |

No surprise that many turn to china custom cnc parts suppliers when deadlines are tight and margins are tighter.

The Role of Material Selection in Custom CNC Parts

✓ Choosing the right material isn’t just smart — it’s mission-critical.

✓ For example:

• Use Stainless Steel when corrosion resistance matters — think marine or food-grade gear.

• Opt for Duplex Steel F51 when high strength is needed under extreme pressure — common in chemical plants.

✓ Material affects not only durability but also machinability and cost-efficiency during production runs with CNC tools.

The bottom line? Every job has its material soulmate — pick wrong, and you’re throwing money away or risking performance failure.

Why Precision Matters More Than Ever

You can’t fake precision — especially not when tolerances are tight enough to make an engineer sweat bullets.

• In aerospace or medical fields, even a few microns off can mean disaster.

• That’s where CNC steps up with its ultra-fine control over every axis of motion during fabrication processes like milling or turning.

And here’s where it gets real: top-tier custom parts made by expert machinists can hold tolerances within ±0.005mm consistently across thousands of units.

When you’re sourcing from top-rated china custom cnc parts suppliers, that level of accuracy becomes standard issue — not wishful thinking.

Common Applications Served by Chinese CNC Suppliers

You’ll find these guys behind more than just auto parts:

🚀 Aerospace components like brackets & housings

🛢 Oil & gas pipeline fittings including Tees & Elbows

🔬 Medical devices requiring sterile-grade finishes

🏗 Industrial machinery replacement parts

Each sector demands different specs — but all rely on the same thing: consistent quality from reliable sources like China’s industrial base.

So next time you twist a valve or bolt down a housing unit, chances are good some part came outta Shenzhen or Ningbo!

Comparing Materials Used by Top Chinese Manufacturers

Let’s group some common choices based on application type:

— High Corrosion Resistance: • Stainless Steel SS304 • Titanium Alloy Grade V

— High Strength Under Load: • Carbon Steel A105 • Alloy Steel ASTM A182 F22

— Chemical Resistance: • Duplex Stainless Steel F51 • PTFE-coated Aluminum Alloys

These materials aren’t just picked at random — each offers unique combinations of tensile strength, thermal resistance, and machinability that align perfectly with specific end-use scenarios across industries sourcing from leading china cnc machining services providers.

What Makes Chinese CNC Suppliers Stand Out?

It ain’t luck that keeps clients coming back:

- 📦 Shorter lead times thanks to integrated supply chains within cities like Suzhou and Guangzhou

- 💰 Competitive pricing without skimping on quality control standards

- 🧰 Access to cutting-edge multi-axis machines + experienced operators trained via national vocational programs

In fact, some shops even offer real-time order tracking through cloud platforms tied into their ERP systems — talk about transparency!

As demand grows worldwide for tailored components, having go-to relationships with trusted partners like those at yuuhuan hongqian can seriously streamline your procurement game plan.

Final Thoughts: Why Smart Buyers Choose China for Custom Parts

Smart buyers don’t gamble—they calculate risk vs reward:

→ Need fast turnaround? Go where the machines never sleep: China’s factories run round-the-clock shifts year-round.

→ Want reliable specs? Many shops are ISO-certified with full traceability baked into their production workflow using barcodes + digital logs tied directly into CAD files.

→ Budget-conscious? Even after factoring shipping costs, total landed price often beats domestic options hands-down while maintaining solid QC benchmarks set by international buyers’ audits regularly conducted onsite.

So if you’re weighing your next move… consider this your sign: working with seasoned pros among today’s best-performing china custom cnc parts suppliers might just give you the edge you’ve been looking for!

5 Key Qualities of Reliable CNC Parts Suppliers

Finding dependable china custom cnc parts suppliers isn’t just about price—it’s about trust, consistency, and technical know-how. Here’s what separates the best from the rest.

Proven Expertise in CNC Machining and Material Processing

- ✅ Deep background in CNC machining with high-tolerance results

- ✅ Mastery over specialized machining processes like Threading NPT and TIG Welding

- ✅ Familiarity with demanding materials such as Alloy Steel F11, Inconel, and duplex stainless

- Years of hands-on experience with complex geometries

- Ability to deliver custom parts for sectors like aerospace, oil & gas, and medical tech

- Skilled in both prototyping and full-scale production

★ Suppliers who’ve nailed down their technical capabilities can handle sudden design changes without missing a beat.

Their team should not only talk shop but walk it—think multi-axis setups, tight tolerances, and finishing finesse that doesn’t need rework.

Short runs? High-volume batches? Doesn’t matter. The right supplier adapts on the fly while keeping your specs locked tight.

From precision boring to heat treatment integration, top-tier china cnc parts suppliers bring serious manufacturing expertise to every job.

Certification Compliance: Ensuring Adherence to International Standards

• ISO 9001-certified operations ensure rigorous internal systems are followed daily

• ASME B16.11 compliance guarantees pressure integrity for high-risk assemblies

• MSS SP-97 standards confirm reliability for branch connections used in Power Generation

1) Certified suppliers reduce risk—no guesswork when it comes to safety-critical components

2) They maintain traceability with valid material certifications, so no surprises during audits

“By 2024, over 78% of global procurement managers listed ‘certification transparency’ as a top factor when choosing industrial partners,” according to Frost & Sullivan’s latest manufacturing report.

The best china custom cnc parts suppliers already meet or exceed international norms—so you don’t have to chase them down for paperwork later.

Quality Control Practices: From Hydrostatic Testing to Dimensional Inspection

Group A – Dimensional Accuracy:

• Uses advanced CMMs (dimensional inspection) tools for micron-level accuracy

• Every part gets checked against CAD specs before shipping

Group B – Structural Integrity:

• Applies pressurized fluid checks via hydrostatic testing on valves or fittings under load conditions

• Leverages X-ray-based methods like radiographic inspection for weld seams

Group C – Defect Prevention:

• Integrates inline sensors during milling operations to detect tool wear instantly

• Performs random batch sampling using non-contact laser scanning tools

Quality isn’t just a checkbox—it’s an obsession. Trustworthy suppliers build QC into every step instead of tacking it on at the end.

Reliable vendors don’t wait until final inspection; they bake quality into each pass—from rough cut through finish grind.

Strong Supply Chain Management and Timely Delivery

✔ Real-time tracking systems keep clients updated on order status without needing follow-ups

✔ Smart inventory planning prevents raw material delays during peak demand seasons

✔ Agile logistics networks ensure fast delivery—even across borders

Step 1: Forecast demand based on historical order patterns from recurring customers.

Step 2: Sync production schedules with shipping availability windows.

Step 3: Monitor supplier health upstream so no one drops the ball mid-project.

A good supplier won’t ghost you after PO approval—they’ll guide your order all the way home.

With solid supply chain management, even complex items like concentric reducers arrive ready-to-install at water treatment plants or HVAC sites—no excuses, no drama.

When you’re working with experienced china cnc parts suppliers, “on-time” becomes standard—not a lucky break.

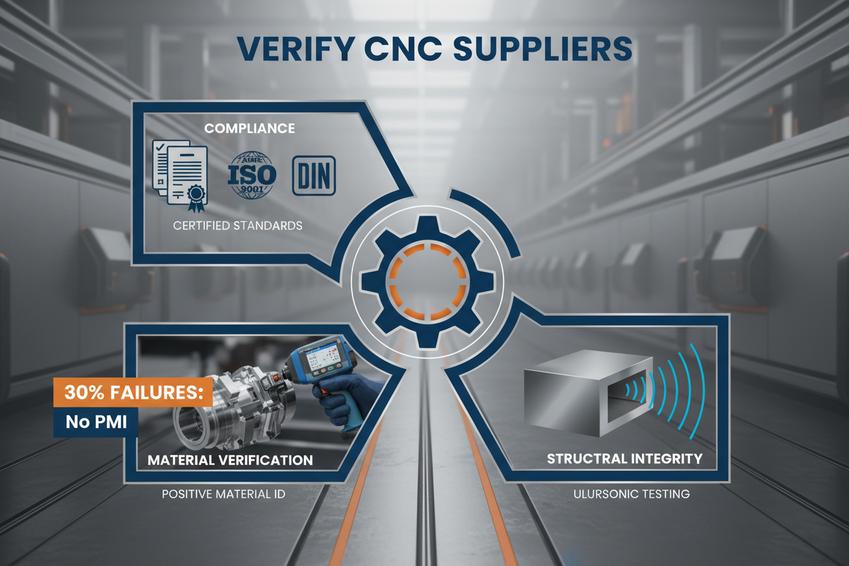

How to Verify China Custom CNC Parts Suppliers’ Credentials

Before teaming up with any supplier overseas, especially when it comes to precision parts, it’s smart to know exactly who you’re dealing with.

Checking Supplier Certifications: ASME B16.11, MSS SP-97, and More

When choosing among various china custom cnc parts suppliers, don’t skip over the paperwork. Industry certifications are your first signal that a company knows what it’s doing.

- ASME B16.11: Confirms the supplier can produce forged steel fittings up to spec—ideal for high-pressure applications.

- MSS SP-97: A must-have if you’re sourcing branch outlet fittings; ensures compatibility and safety.

- DIN 2605 & ISO 9001: These prove international compliance for pipe bends and quality systems.

- Internal audits and third-party checks often validate these certifications—ask for audit reports.

- Always verify document authenticity through issuing bodies like ANSI or ISO registries.

If your potential partner shrugs off certification questions? That’s your cue to walk away.

The Role of Positive Material Identification in Ensuring Quality

You don’t want mystery metal showing up at your site. That’s where Positive Material Identification (PMI) steps in—it tells you exactly what alloy you’re dealing with.

PMI tools use X-ray fluorescence or optical emission spectroscopy to verify materials like:

• Carbon Steel (A105)

• Stainless Steel (304/316)

• Nickel Alloys

Shortcuts here can mean disaster later—especially in pressure-sensitive setups like chemical plants. PMI testing confirms both the material’s chemical makeup and its compliance with customer specs.

Quick tip? Ask suppliers how often they recalibrate their PMI equipment. If they hesitate, that’s a red flag waving hard.

And according to TÜV Rheinland’s 2024 report on global industrial quality control trends, “Suppliers without regular PMI verification protocols were involved in over 30% of downstream failures.” That stat alone should make anyone pause before signing a PO.

How to Use Ultrasonic Testing Reports for Verification

Ultrasound isn’t just for babies—it’s also one of the most trusted ways to check metal integrity from the inside out. For buyers scanning through options among custom cnc parts suppliers in China, understanding those UT reports is key.

Here’s what matters:

▪️ Look for signs of internal flaws—cracks, voids, inclusions—all flagged by amplitude levels on the report.

▪️ Check whether the test meets ASTM E2375 standards; this ensures consistency across different batches.

▪️ Match tested items against purchase orders using serial numbers embedded within the report itself.

Also important? Review who performed the test—a certified Level II NDT technician adds serious credibility here.

In power generation environments where failure is not an option, ultrasonic testing backs up every weld and fitting with real data—not just promises from a sales team halfway across the world.

Negotiation Tips with Your China Custom CNC Parts Supplier

Want better pricing from your China custom CNC parts suppliers? Smart negotiation starts with knowing your stuff—especially when it comes to finishes and material standards.

Leveraging Knowledge of Surface Treatments to Negotiate Better Deals

Knowing how different surface treatments affect both cost and durability can give you serious bargaining power when working with China custom CNC parts suppliers.

- Electroplating, Anodizing, and Powder Coating aren’t just cosmetic—they influence corrosion resistance, longevity, and overall value perception. The more you know, the less likely you’ll overpay.

- Suppliers often bundle basic finishing options into quotes—challenge that. Ask what’s optional versus standard. Use this to push back on price or swap in a cheaper alternative like Passivation if high-end isn’t needed.

- If you’re sourcing Brass C36000, bring up how well it takes to Electro Polishing—then ask for volume discounts based on simplified finishing processes.

By showing fluency in finish types and their real-world impact, you shift the conversation from a passive buyer-seller exchange into a strategic discussion about value optimization—and that’s where deals get made.

Understanding Standard Types and Material Specifications for Cost-Effective Deals

When you’re deep in talks with your go-to China custom CNC parts supplier, tossing around terms like “JIS B2311” or “SS304” isn’t just flexing—it’s saving money.

• Know your metals: For instance, switching from Stainless Steel SS316L to SS304 can cut costs without killing performance—especially in non-corrosive environments like indoor water filtration units.

• Understand tolerances: Over-specifying tight tolerances adds machining time and cost. Unless your component lives inside a jet engine, ±0.05mm might be overkill.

• Talk bulk: If you’re ordering large quantities of fittings for municipal water treatment projects, referencing industry specs like JIS B2311 helps streamline procurement—and shows you’re not new to the game.

Being sharp on material grades, tolerancing norms, and regional spec codes makes negotiations smoother—and often shorter—with your favorite custom machining crew across the Pacific.

FAQs about China Custom CNC Parts Suppliers

What qualities define trustworthy China custom CNC parts suppliers?

Reliable partners show skill in CNC Machining, Threading NPT, and Welding TIG on materials such as Alloy Steel F11 or Stainless Steel 304.

- Their work must reflect standards like ASME B16.11 and MSS SP-97, key for fittings used in Power Generation Systems.

- Quality control includes:

- ✅ Hydrostatic Testing to confirm pressure stability,

- ✅ Radiographic Inspection ensuring internal soundness,

- ✅ Dimensional Inspection preserving exact fit of every machined part.

How do these suppliers serve Oil and Gas Pipelines projects worldwide?

They produce precision fittings—such as an Elbow 90 Degree, a perfectly wrought symbol of flow—delivered from foundries through coordinated supply chains. Using materials like Carbon Steel A105, their efforts power international pipeline expansions while balancing quality with affordability.

Why is material choice so critical when selecting china custom cnc parts suppliers?

Each alloy tells its own story:

| Material | Typical Use | Notable Advantage |

|---|---|---|

| Duplex Steel F51 | Corrosive liquid service lines | High strength & rust resistance |

| Brass C36000 | HVAC systems connectors | Excellent machinability & sealing performance |

Selecting the right one defines durability under heat, pressure, and chemical attack within Chemical Processing Plants or long-term piping networks.

Which certifications assure buyers before signing bulk contracts?

Only those workshops aligning with:

1️⃣ ASME B16.11: Essential for accurate shaping of threaded elements like a Coupling Full.

2️⃣ DIN 2605 / EN 10253: For precise bending geometry in elbows and tees installed across massive facilities such as refineries or waterworks.

How can surface treatments influence both price and life cycle?

Finishing is more than beauty—it’s protection mixed with art. Options include:

- ✳️ Electro Polishing: smooths stainless interiors to resist corrosion; ideal for food-grade components.

- ✳️ Galvanizing Hot-Dip: coats carbon steel for outdoor applications across Oil fields.

Negotiating treatments early helps balance budget against longevity expectations of each piece—from a petite Union Threaded to full-scale pipe runs.

What inspections matter most before shipment from factories?

Before boxes leave the floor coated by light sandblasting dust, engineers run exhaustive checks:

• Ultrasonic Testing — listens deep inside forged metal for invisible flaws after the Forging Hot process;

• Positive Material Identification — confirms that no inferior alloys slipped past processing;

• Hydrostatic Testing — makes sure every Reducer Concentric stands tall under extreme pressure typical in Water Treatment Facilities setups.