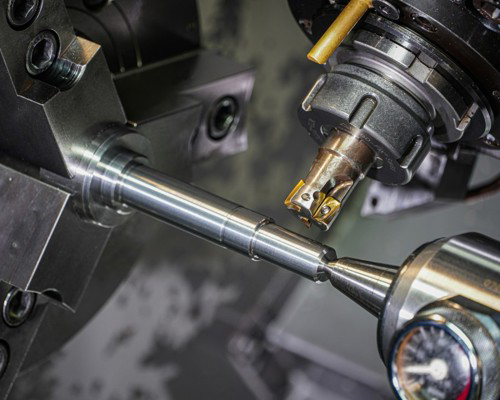

For factories specializing in machining steel fittings, the CNC lathe is the core equipment driving daily production. Steel materials generate heavy chips and tend to rust easily, making proper maintenance essential for protecting machine accuracy and extending equipment lifespan. Whether your workshop runs a cnc lathe machine, cnc turning machine, or other cnc turning equipment, a systematic maintenance plan ensures stable production, high-quality cnc parts, and reduced downtime.

Below is an optimized and practical maintenance guide tailored specifically for CNC lathes used in steel machining environments.

Daily maintenance is the foundation of machine health. Before and after each shift, operators should carry out basic inspections and cleaning to protect the equipment.

Steel chips are sharp, abrasive, and corrosive. They may get stuck inside covers, slideways, or tool holders.

Clear chips from the chuck, tool turret, guideways, and chip conveyor.

Clean coolant splashes on surfaces to prevent rust.

Keep the working area dry to minimize corrosion.

This step greatly reduces wear on precision components in a cnc lathe machine.

Lubrication is essential for any cnc machine, especially for lathes cutting steel.

Confirm that the automatic lubrication pump is functioning.

Check oil level and refill when necessary.

Apply anti-rust oil on guideways and ball screws daily.

Proper lubrication minimizes friction, prevents rust, and keeps the lathe running smoothly.

Verify air pressure is stable.

Drain accumulated water from air filters.

Check hydraulic oil levels for machines with hydraulic chucks.

Ensure coolant level and concentration meet cutting requirements.

Daily checks prevent sudden failures during production.

Weekly maintenance focuses on deeper cleaning and inspection of mechanical functions on your cnc turning machine.

Coolant tanks accumulate sludge, rust particles, and bacteria.

Clean filters to ensure proper coolant circulation.

Remove steel sludge at the bottom of the coolant tank.

Proper coolant quality prevents rust on cnc parts and machine components.

Ensure the hydraulic chuck operates smoothly without leakage.

Check turret alignment and confirm smooth tool indexing.

Tighten tool holders and check for abnormal wear.

These checks maintain cutting accuracy and prevent tool-related failures.

Dust reduces cooling efficiency and may cause overheating.

Clean or replace filters to keep ventilation smooth.

Electrical stability is crucial for all cnc turning equipment.

Monthly maintenance is more technical and helps detect deeper mechanical or electrical issues before they become major problems.

Inspect guideway clearance and ensure smooth movement.

Check axial play of the ball screw and listen for abnormal noise.

This ensures the long-term cutting accuracy of your cnc lathe machine.

The spindle is the core of every cnc turning machine.

Clean the spindle taper with light oil.

Check spindle runout and vibration levels.

Inspect belts and tighten if required.

A healthy spindle extends the machine’s life and ensures stable machining accuracy.

Clean dust around motor surfaces.

Check cable insulation for cracks.

Tighten loose connections.

This ensures precise control of feed axes and prevents system alarms.

Regular backups prevent production downtime in case of data corruption or power failure.

Correct operation habits are as important as regular maintenance. Improper use can damage even the best cnc turning equipment.

Overloading causes spindle overheating, vibration, and poor tool life.

Always follow recommended cutting parameters for steel turning.

Keep the chuck jaws clean and rust-free.

Clamp the workpiece securely and evenly.

Incorrect clamping causes vibration and affects accuracy.

Operators should pay attention to:

Unusual motor noise

Increased vibration

Spindle heating

Coolant pump noise

Sudden changes in cutting sound

Early detection prevents serious machine damage.

High-quality inserts and stable coolant reduce wear and ensure accuracy when machining cnc parts.

Steel machining creates a harsh environment:

Heavy steel chips

High cutting heat

Coolant contamination

Rust formation due to humidity

These factors can quickly damage guideways, turrets, and spindle bearings if maintenance is neglected.

By maintaining your cnc machine regularly, you ensure:

Longer equipment lifespan

More stable machining accuracy

Better surface finish

Lower repair costs

Higher production efficiency

For factories using cnc lathe machines to produce steel fittings, proper maintenance is the key to long-term stability and high-quality output. By combining daily cleaning, weekly inspections, monthly calibration, and correct operating habits, your workshop can maintain peak performance, reduce downtime, and produce consistent, precise cnc parts.

Good maintenance is not just a routine—it is an investment in your equipment, your production efficiency, and your business competitiveness.