As a pipe fittings supplier ,we have expereience more than 8 years to produce various pipe fittings ,especially in steel pipe fittings .

We are familiar with Q235 ,ANSI 1020, ANSI 1045,42CRMO with different demand for the cnc turned parts ,like black oxidation , zinc plated , electrophoresis.

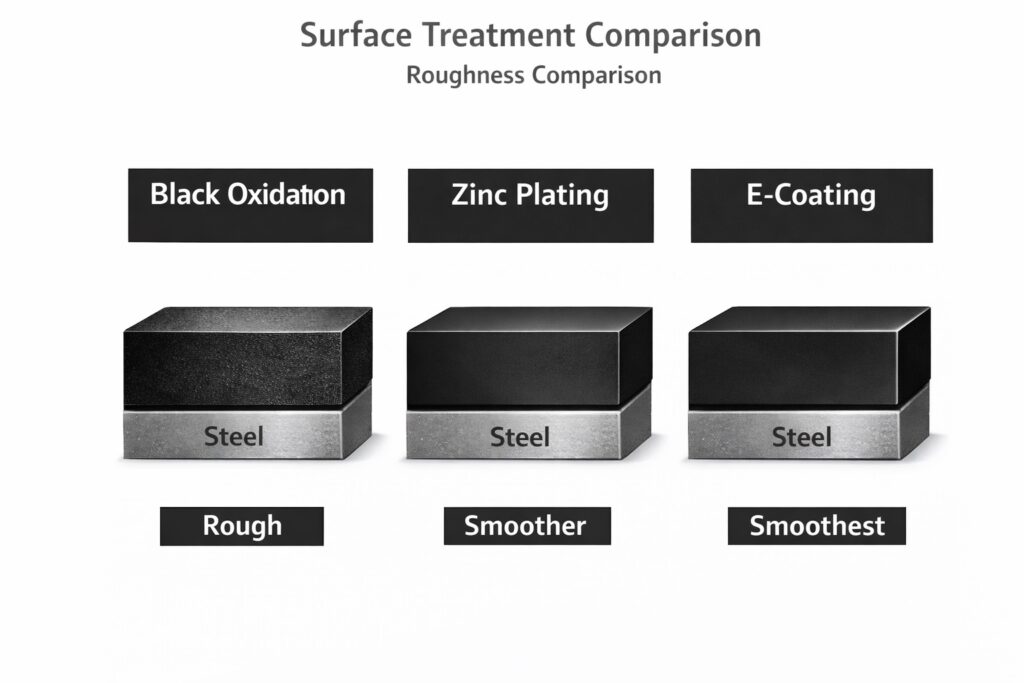

Today we discuss what the different between this three type surface treatment .

What is black oxidation ?

Black Oxidation (Blackening / Black Oxide)

-

Definition: Forms a thin black oxide layer (Fe₃O₄) on steel surfaces, mainly for corrosion resistance and aesthetics.

-

Surface Appearance: Black with slight gloss, metallic texture visible; needs oil for better rust protection.

-

Coating Thickness: Very thin, typically 0.5 μm-1.5UM

-

Applications: Hex nut , bolt and pipe fittings.

what is zinc plated ?

-

Definition: Electroplating a layer of zinc (Zn) on steel to protect against corrosion via sacrificial anode effect.

-

Surface Appearance: Silver or bluish-silver, can be bright or matte; more corrosion-resistant than black oxide.

-

Coating Thickness: About 5–25 μm, depending on process (thin for electroplating, thick for hot-dip galvanizing).

-

Applications: Screws, hardware, construction parts, hydraulic fittings, Automotive parts.

what is electrophoresis ?

-

Definition: Uses an electric field to deposit charged paint particles on metal, forming a uniform coating, usually baked to cure.

-

Surface Appearance: Smooth, uniform, color customizable (black, gray, white, etc.); high corrosion resistance.

-

Coating Thickness: Around 15–30 μm, thicker than black oxide and comparable to or slightly thicker than zinc plating.

-

Applications: Automotive parts, bicycles, electrical enclosures, metal parts requiring long-term corrosion protection

| Feature / Property | Black Oxidation (Black Oxide) | Zinc Plating (Galvanization) | Electrophoretic Coating (E-coating) |

|---|---|---|---|

| Definition | Oxide layer on steel | Zinc layer for corrosion | Electro-deposited paint coating |

| Color | Black | Silver or bluish-silver | Various colors (black/gray/white) |

| Surface Feel | Slightly rough | Smooth / metallic | Smooth, coated feel |

| Coating Thickness | 0.5-1.5μm,my opinion it same with beofore coating . | 5–25 μm based on demand . | 20–30 μm |

| Corrosion Resistance | Low (needs oil) | Medium | High |

| Applications | Tools, screws, mechanical parts | Hardware, screws, construction | Automotive, bicycles, electronics |

How to solve the mistake surface treatment of black oxidation , zinc plated , electrophoresis ?

We are the factory professional supply different types of pipe fittings , include hex nipples and bolts , that one time we get hydraulic fitting order, it is a hex nut order with black oxidation,mateiral is ANSI 1020 (20# steel parts ) ,9/16-18UNF thread.

But in the production , Thread gauge failure , the threads of the entire batch hex nut thread is too loose to export . So we think if it is possible to change the surface treatment but add thickness . Finally we choose the zinc plated solve the problem .

Why we choose zinc plated instead of electrophoresis for hex nut ?

1- Surface : black oxidation surface is similar with zinc plated .After zinc plated , the only differnt is no oil ,and surface little better than black oxidation, hard to find the problem when get the goods. Electrophoresis is too beatiful and smooth and easy to find the different .

2-Coating thickness : Inner thread is a little loose that zinc plated could produce based on our demand . Electrophoretic Coating is one side 20UM ,it means need add 40-60 um total in thread . it can not approve by the thread gauge test . Our mainly problem is solve the thread problem.

3-Cost Comparison : Electrophoretic cost is double price compare the zinc plated .

Finally we choose the black zinc plated to solve the problem.

Faq :

Is that all carbon steel can use black oxidation , zinc plated ,electrophoresis ?

Yes , steel fittings can choose this three types surface treatment , but notice the price different .

black oxidation< zinc plated <electrophoresis ,it means black oxidation is cheapest.

Which type can avoid steel rust problem ?

electrophoresis is best choice . Zinc plated need at least 10um thickness then similar with electrophoresis surface treatment .

Conclusion :

Yuhuan hongqian machinery co.,ltd is professional supply various pipe fitting with oem cnc turning service . We are professional supply custom made cnc turning parts and provide steady quality pipe fittings .Welcome to contact us for your pipe fitting projects .