In china , we have million of cnc turning parts manufactures . It focus on produce different type cnc turning parts.

It can be divided into different area ,like : hydraulic fitting ,automobile parts, construction parts , gas fitting, pneumatic connector etc.

Our factory is located in zhejiang province ,that zhejiang businessman is good quality and cheap price , good reputation in the world .

Compare the low quality hebei , high price in guangzhou . Choose zhejiang cnc turning manufacture,is one of the best choice for middle demand customers.

Yuhuan hongqian machinery co.,ltd is a customized cnc turning parts manufacture .

We keep focus on help customer custom made metal parts .

When the goods is hard to find in the market , and customer want a unique design different with other customer .

We can provide oem cnc tuning service . odm cnc machine service .

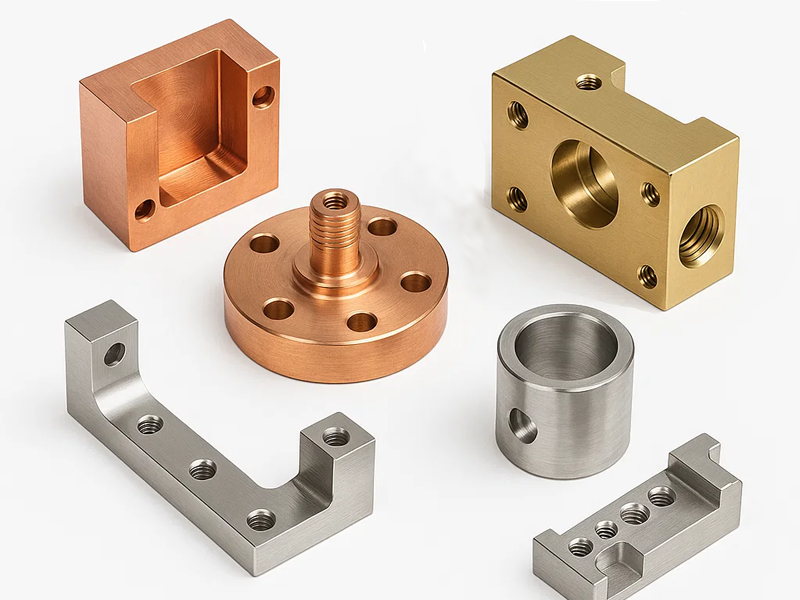

CNC turning offers fast, accurate, and cost-efficient production for a wide range of metal parts. With computer-controlled machining, it delivers tight tolerances, stable repeatability, and smooth surface finishes, making it ideal for shafts, bulkhead fittings, adapter fittings, and custom precision components. The process supports stainless steel, carbon steel, aluminum, and brass, giving manufacturers strong flexibility for different industries and environments.

Cnc turning process is suitable to produce small batch and big batch goods . It is suitable to produce bulkhead fittings ,pipe fittings with fast produce . and low price . It is have big advantage when you want circle ,hex, thread turning process .

CNC turning and CNC milling are both essential machining methods, but they operate in very different ways. CNC turning works by rotating the workpiece while a cutting tool removes material, making it ideal for producing round or cylindrical parts such as shafts, bushings, and threaded fittings. It offers excellent speed, tight tolerances, and smooth surface finishes for symmetrical components.

In contrast, CNC milling keeps the workpiece stationary while the cutting tool rotates and moves across multiple axes. This makes milling better suited for prismatic or complex shapes with flat surfaces, pockets, slots, and contours. Milling can produce more detailed geometry, while turning is faster and more efficient for circular parts.

In short, turning is best for round components, and milling is best for detailed or multi-surface parts. Many manufacturers combine both processes to achieve high precision and complete custom machined components.

CNC turning is generally much more cost-effective because the machine itself is cheaper, and the cutting tools are low-cost. In many cases, a CNC milling machine can be five times more expensive than a turning machine, and milling tools also cost significantly more to maintain and replace. Turning is also faster, requiring fewer movements and shorter cycle time, while milling is slower due to complex tool paths. As a result, CNC turning offers lower production cost and higher efficiency, especially for round or simple parts.

1-which type service you provide ?

Cnc turning service , cnc machined parts service .

2-Which type producets you can supply ?

bulkhead fitting , steel plug , hexagonal nuts, adapter fitting , fastener ,hex bolt ,elbow connector , T connecor and other different type pipe fittings .

3-What material you can produce ?

brass ,copper , carbon steel (1020,1035,1010,1045,42crmo, 40cr , Q235 etc), aluminum 6061,6063.

4-which type suraface treatment you can provide?

Pickling, anodizing, blue-white zinc plating, color zinc plating, blackening, phosphating.

5.How many machines does your company have?

70 CNC lathes machine, several stamping machines, tapping machines, drilling machines, grinding machines, one laser marking machine, and one optical projector.

6. Can you provide material testing reports?

We can use a spectrometer to test whether the materials meet the standards.

7. Can you provide quality inspection reports?

We can provide dimensional reports, electroplating inspection reports, and material inspection reports

We are the provide custom precision cnc turned parts in china . So it is necessary you provide the samples or 2D/3D drawing to our team. We will study the tolerance ,material , surface treatment . Study our technical if could satisfy your demand .Then will provide the suitable price and detail to you .