Hongqian offers a diverse range of metals for CNC machined pipe fittings, including carbon steel ,stainless steel ,Aluminum ,Brass fittings.

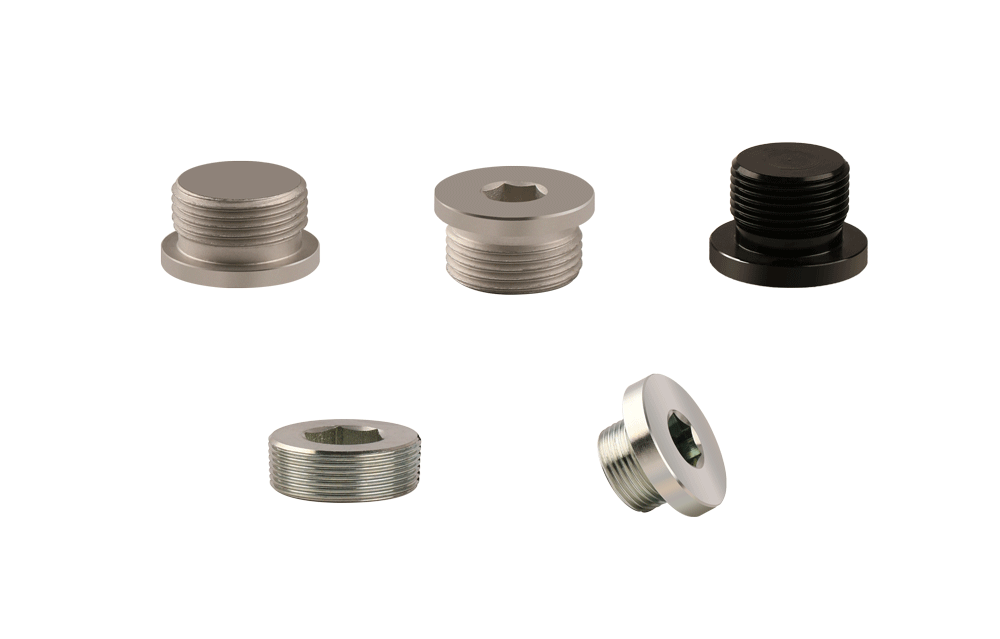

We manufacture various custom parts such as threaded pipe fittings, hydraulic adapters, bushings, and connectors — ideal for one-off prototypes as well as end-use CNC components.

The selection of materials for machined parts is an important task, which directly affects the quality, performance and cost of the parts. The principle for selecting materials for mechanical parts is: the required materials should meet the usage requirements of the parts and have good craftsmanship

| Image | Name | Description | Surface Treament |

|---|---|---|---|

| Stainless Steel | Good machinability + High tensile strength + Corrosion resistant | Nickle plated , passivation,chrome plated,polish , clean surface. |

| Steel | Good machinability + High tensile strength + Good ductility and weldability | Zinc plating, Nickel plating, Chrome plating, Black oxide, Heat treatment, Carburized, electrophoresis, Chemical nickel, Blackening treatment, Antirust oil |

| Aluminum | High machinability + Good strength-to-weight ratio | Chrome Plating,Anodizing |

| Brass | Good machinability + Excellent electrical conductivity + Low friction + Golden appearance | Acid cleaning, Nickel plating, Chrome plating, Polishing |

We manufacture stainless steel 201 pipe fittings ,hex nuts with CNC turning process for industrial applications. Stainless Steel 201 is an economical austenitic stainless steel grade with good strength and moderate corrosion resistance.

Stainless Steel 201 vs 304 – Key Differences

201 Stainless Steel: Low nickel, high manganese, low cost but more easy rust .

304 Stainless Steel: Higher nickel content,but compare stainless steel 201 is higher cost.

The SS303 grade of stainless steel has excellent corrosion resistance and durability. These properties make SS303 ideal for the metal fabrication of gears, shafts, bushings, nuts and bolts, and aircraft fittings.

The 303 stainless steel grade contains 17% chromium, 8% nickel, and 0.15% sulfur. However, this sulfur content makes it impossible to harden this metal through heat treatment.

This is one of the most common stainless steel grades used for machining. The advantages of 304 stainless steel are mainly reflected in:

The SS316 grade of stainless steel has incredible corrosion resistance and strength. This corrosion resistance is due to its 2% to 3% molybdenum content asides from its chromium and nickel content.

The high strength of SS316 gives it specialized use in both aerospace and medical implants.

| Material | US Standard / AISI | Carbon Content (%) |

|---|---|---|

| 1020 | AISI 1020 | 0.18–0.23 |

| 1045 | AISI 1045 | 0.43–0.50 |

| 20# | AISI 1015–1020 | 0.17–0.24 |

| Q235 | AISI 1015–1020 | 0.14–0.22 |

| Q355 | AISI 1020–1045 | 0.14–0.22 |

| 42CrMo | AISI 4140 | 0.38–0.45 |

| 12L14 | AISI 12L14 | 0.12 |

| Y15 | AISI 1015/1020 | 0.12–0.15 |

| 40Cr | AISI 5140 | 0.37–0.44 |

AL6061 – This is the most common general-purpose aluminum grade, usually used in auto parts, bicycle frames, sporting goods, remote control car frames, etc. Similar to other aluminum alloys, it has a good strength-to-weight ratio and is inherently resistant to atmospheric corrosion. ability. This material is very workable and workable, but it can be more expensive than other metals and it doesn’t perform as well when exposed to salt water or other chemicals, depending on the product’s use.

AL7075 – A higher grade of aluminum, 7075 is one of the strongest aluminum alloys. Unlike 6061, AL7075 is strong but has average workability, making it difficult to bend into difficult and complex shapes. The material is high strength Ideal for recreational equipment, automotive and aerospace frames, these applications require the metal to withstand regular stresses and should be avoided where welding is required.

This is the aluminum grade commonly used for machining. Of all the 6000 series, the 6082 has the highest strength, even stronger than the 6061.

Its strength is due to its large amount of manganese, which controls its grain structure. The 6082 has excellent corrosion resistance making it ideal for use in the aerospace and defense industry.

The type of metal chosen often determines the time spent machining it. Selecting a metal with low machinability would extend the CNC machining time considerably, as opposed to selecting a metal like aluminum with its high precision machinability. Furthermore, the longer the time spent machining, the more expensive the manufacturing process becomes.

Another factor that determines machining time is the complexity of the parts. A CNC machine would spend more time machining a complex part than a simple part, which also increases CNC machining costs.

The proposed use of CNC machined parts is another factor that would determine the choice of metal. For instance, when making parts that would experience heavy stress and loading, a metal with high strength, like steel alloy, is better than copper.

On the other hand, where the final product should have strength similar to steel but without its weight, like in the manufacturing of aircraft, then titanium might be ideal.

Additionally, the environment in which the part would operate is another factor that should determine the metal used for making the part.

The type of metal selected also determines the finishing and post-processing of the machined parts. For instance, soft metals or hard metals with low machinability often have tooling marks and burs, which finishing and post-processing help remove.

Although finishing and post-processing improve the appearance of a metal part, it also raises the cost of machining significantly. However, knowing the finishing and post-processing required makes it easier to choose the right metal for part metal fabrication. In most cases, it will be a metal with high manufacturability if a high-quality surface finish is important.

Yuhuan hongqian machinery co.,ltd is a cnc turned parts manufacturer with 80 sets cnc lathe machines , we focus on produce various pipe fittings and provide OEM / ODM CNC serivce for different type material.

Neeed provide 2D /3D drawings include detail demand for raw material , surface treatment , quantity ,heat treatment ,packing demand etc. The more detail you give , the price more accurate.

Yes , we could produce sample pipe fttings based on drawing or customer demand.

7-15 days based on the pipe fitting demand . Such as heat treatment , special raw material may affect the sample delivery time .

We mainly produce carbon steel pipe fittings , stainless steel pipe fttings with more than 10 years, few percent for brass fittings , aluminum pipe fittings.

Within 48 hours based on drawings time may different . Could add our whatsapp for a faster reply.

We supply cnc machinery service for various pipe fittings ,include pipe joint, elbow fittings, plug , screw and bolts , T connector , bushing , thread fittings .