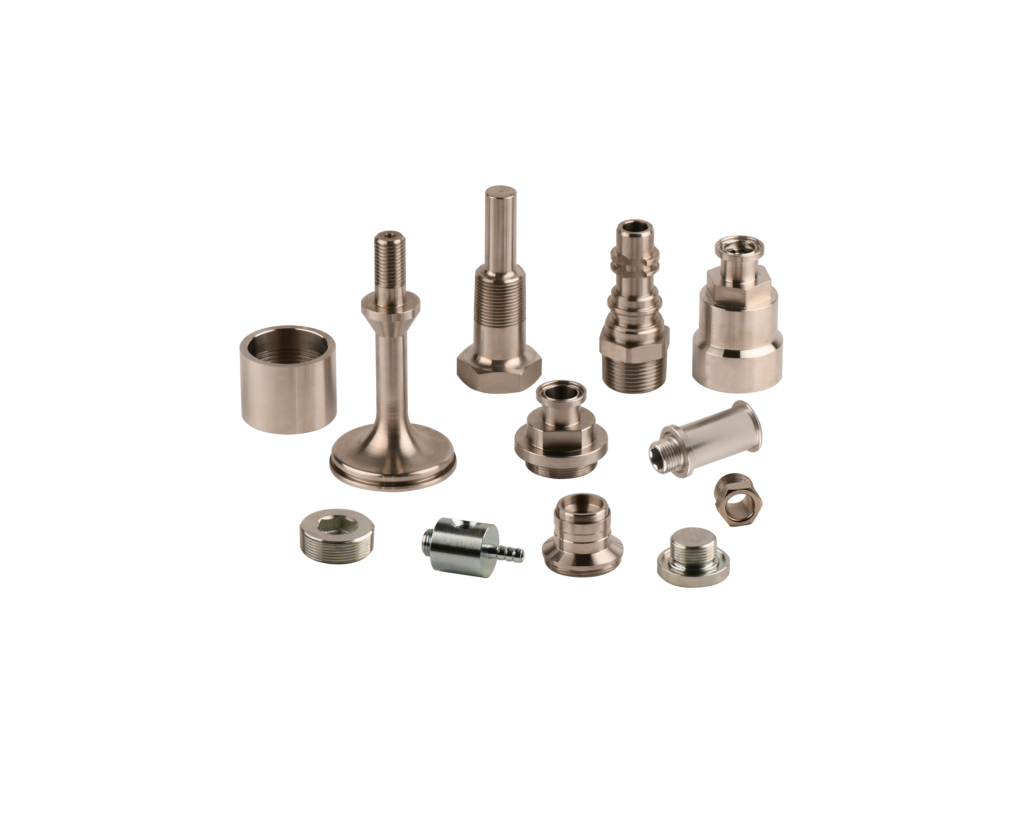

In our industrial area , based on the material, we can divide different types pipe fittings manufacturers.

Mainly we could divide 4 types:

- Brass pipe fitting factory

- Stainless steel pipe fitting factory

- Aluminum pipe fitting factory

- Carbon steel pipe fitting factory .

Based on the material cnc machinery hard level , i think stainless steel is most hard . second level is carbon steel , then aluminum , last is brass .

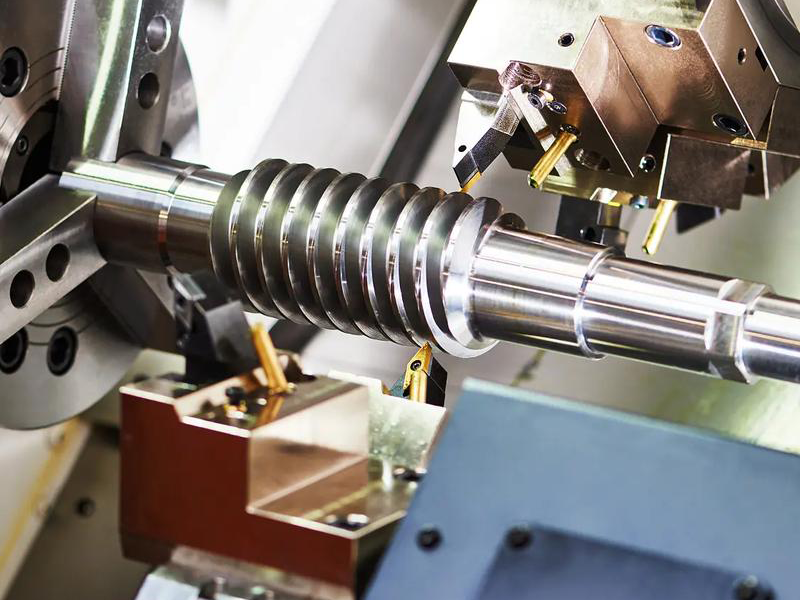

Why Is Stainless Steel the Most Difficult Material for CNC Machining Pipe Fittings?

From the raw material hardness , i think it is more easy to let you know the reason .

| Material | Hardness (HB approx.) |

|---|---|

| Brass (HPB 57/HPB59) | 60–100 |

| Aluminum(6061/6063) | 30–80 |

| Carbon steel (1020 / Q235) | 120–180 |

| Stainless steel (304 / 316) | 150–220 |

Higher hardness means:

-

More cutting resistance

-

Faster tool wear

-

Higher spindle load

This directly increases machining cost and cycle time. In our cnc machinery for pipe fittings , Tooling costs for machining stainless steel are more than double, or even triple, compared to cnc machinery carbon steel material .

Many buyers focus only on price, but our technical data shows how hardness impacts the Spindle Load and Machining Cycle Time, which ultimately determines the final cost

Common stainless teel material table

| Grade | Characteristics | Hardness (Typical) | Primary Applications |

| 201 | Lower cost, some corrosion resistance but prone to rust. | ≤ 217 HBW (95 HRB) | Pipe fitting, HVAC fitting |

| 303 | Excellent machinability, ideal for precision parts. | ≤ 262 HBW (25 HRC) | Hydraulic fitting, Pipe fitting |

| 304 | Most common grade, balanced performance and cost. | ≤ 201 HBW (92 HRB) | Pipe fitting, HVAC fitting |

| 316 | Superior corrosion resistance, standard for Food Grade. | ≤ 217 HBW (95 HRB) | High pressure system, Hydraulic fitting, Pipe fitting |

| 410 | High strength, heat-treatable for hardening. | 38-45 HRC (after hardening) | Specific parts for High pressure systems |

| 420 | High hardness and wear resistance. | 50-54 HRC (after hardening) | High-hardness parts for High pressure systems |

Why 316 Stainless Steel is Harder to Machine than 304 and 303 ?

Based on the stainless steel material table , we can find out one problem that the all stainless steel raw material hardnesss is smilar , but when cnc machinery for stainless steel pipe fittings ,316 is obviously difficult to cut, and tools break far more frequently than with 304,303 material.

The difficulty isn’t about hardness—it’s about toughness and heat:

- 316 (The “Sticky” Grade): Due to the addition of Molybdenum, 316 has a much higher work-hardening rate. The moment the cutter touches the metal, the surface hardens instantly. Combined with its high “stickiness,” this causes heat to build up at the tool tip rather than escaping through chips, leading to frequent tool breakage.

- 304 (The Standard): Without Molybdenum, 304 is less abrasive and “gummy” than 316. While it still requires care, it is significantly more forgiving on cutters during high-volume production.

- 303 (The Free-Machinist): This grade contains added Sulfur, which acts as a built-in lubricant and chip-breaker. It produces brittle chips that snap easily, making it the easiest to machine for precision hydraulic fittings.

Summary: If your project requires Food Grade or High-Pressure resistance, 316 is essential—but it requires professional CNC expertise and specialized tooling to handle its aggressive work-hardening.

Why Similar Hardness Doesn’t Mean Similar Machining: Brass C360 vs. Aluminum 6061 ?

In the world of CNC pipe fitting production, many assume that softer materials are easier to handle. However, comparing Brass C360 and Aluminum 6061 reveals that hardness is only one part of the equation. Each material requires a distinct strategy for quality control and surface finishing.

1. Brass C360: High Value and Material Integrity

Brass C360 is the “gold standard” for machinability, but its high market value introduces a significant financial risk.

-

Pre-Production Testing: Because brass is a high-cost commodity, performing a Spectrochemical Material Analysis before production is non-negotiable. We ensure the alloy meets strict international standards to prevent large-scale scrap and financial loss due to sub-standard raw material.

-

Machining Advantage: It produces small, brittle chips and requires minimal cutting force, allowing for high-speed automated production with incredible tool life.

2. Aluminum 6061: The Challenge of “Stickiness” and Aesthetics

While Aluminum is lightweight and cost-effective, it is technically “gummier” than brass, presenting unique challenges in the CNC process.

-

Galling & Tool Wear: Aluminum tends to “cold-weld” to the cutter (Galling), which can snap tools and ruin surface finishes. This is why we use specialized polished carbide tools and high-pressure coolant.

-

The Secret to Anodizing: If your aluminum pipe fittings require a vibrant, high-end color finish, material selection is the most critical step. We exclusively use Bar Stock (Extruded) or Hot Forging material for parts intended for Anodizing. Unlike cheaper casting materials, high-density bar stock ensures a uniform, brilliant color without the risk of black spots or dullness.

3. Key Differences at a Glance

| Feature | Brass C360 | Aluminum 6061 |

| Machinability | Excellent; Small brittle chips. | Challenging; Long stringy chips. |

| Material Risk | High Value; Requires Lab Testing. | Moderate Value; Requires Source Control. |

| Surface Finish | Natural gold luster; Polishing-ready. | Ideal for Anodizing (requires Bar Stock). |

| Primary Use | High-precision Hydraulic Fittings. | Lightweight HVAC & High-Pressure Systems. |

Why Choose Us for Your Fitting Production?

Understanding these nuances allows us to optimize the manufacturing process for both cost and quality. Whether it’s ensuring the chemical purity of your Brass C360 fittings or selecting the perfect Aluminum bar stock for a premium anodized finish, we provide the technical expertise to deliver parts that meet your exact specifications.

Conclusion:

Choosing the Right Partner for Your pipe Fitting Projects Selecting a manufacturer involves more than comparing prices.As a professional stainless steel pipe fitting and carbon steel pipe fitting factory , we are not only understand my professional area but also include brass and aluminum fittings . Especially when you have the project for new products , my professional knowledge could help you avoid mistake and save the project hide cost and risk .

Looking for a reliable manufacturer for your next project? Contact us today for a technical consultation or a quick quote.