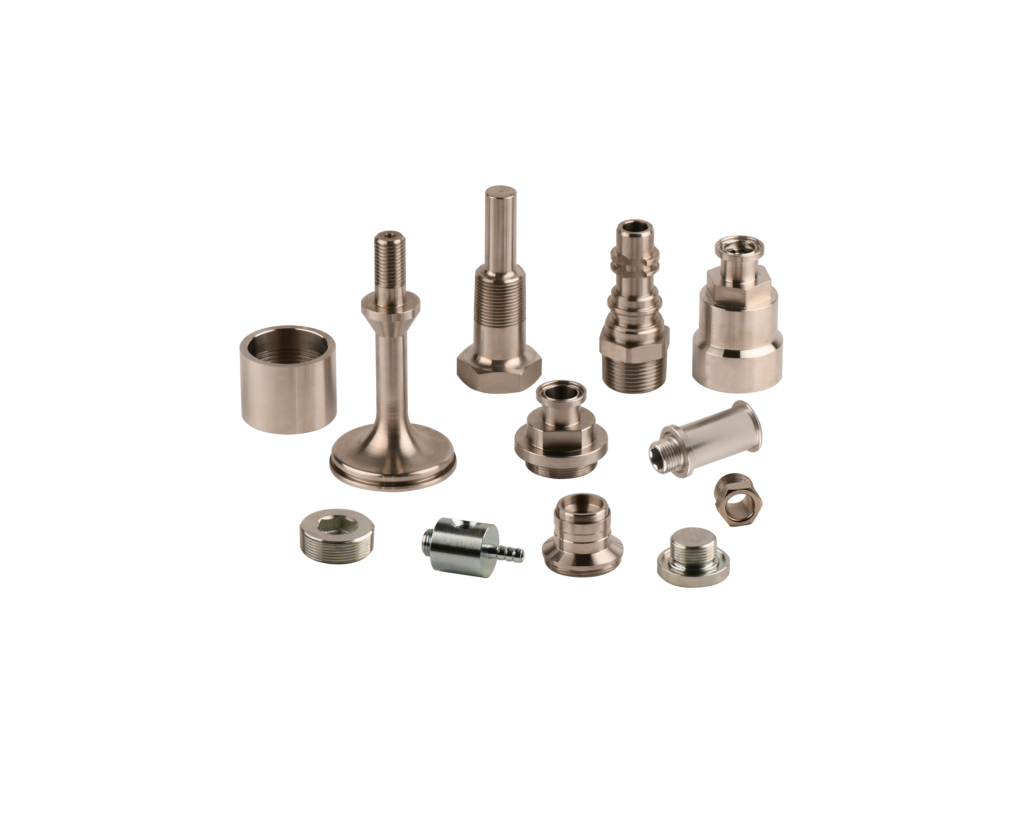

In the modern cnc production area , we divide two simply parts for cnc parts : standard parts and non-standard parts .

In global machining supply, buyers often choose between standard parts and non-standard custom components when sourcing metal fittings, hydraulic connectors, and precision metal parts. Standard parts are defined by ISO, DIN, GB, and ANSI specifications, meaning thread size, tolerances, material grade, and surface coating follow unified industrial standards. Because of their universal interchangeability, standard screws, nuts, sealing washers, elbow fitting,thread fitting,locating pins, and bearing elements can be procured directly without redesign, making them ideal for fast replacement cycles and cost-sensitive applications.

On the other hand, non-standard CNC parts (also referred to as custom machined components) are engineered according to specific design drawings, functional requirements, sealing structures, or special thread forms such as UNF, NPT, BSPT, or metric fine threads. These components are used where standard fittings cannot meet performance targets, especially in hydraulic block manifolds, automotive turning inserts, automated equipment fixtures, and pressure-resistant connectors.

Yuhuan honqian machinery co.,ltd focus on to provide oem cnc machining service and odm cnc turning service . Especially in hose fitting ,bulkhead fittings, hydraulic fittings . With OEM CNC turning service, dimensions, tolerance bands, plating thickness, and assembly geometry are fully customized, allowing manufacturers to achieve higher reliability in extreme environments such as offshore platforms, chemical plants, and precision fluid control.

As global industries expand into automation and high-precision assembly, choosing between standard CNC components for immediate interchangeability and custom non-standard turning solutions for functional optimization becomes a strategic decision. Whether sourcing OEM CNC parts for strict drawing compliance or developing non-standard custom CNC machining for prototype validation and low-volume runs, partnering with a certified multi-axis turning supplier ensures accurate tolerances, stable lead times, and international material traceability for long-term production.

OEM vs ODM Comparison

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Ownership | Client provides full design and specifications | Manufacturer leads product design |

| Intellectual Property | Belongs to the client | Belongs to the manufacturer unless purchased |

| Core Role | Precision production and manufacturing execution | Product development + manufacturing integration |

| Customization Level | Fully customized based on client drawings | Semi-custom or full turnkey design |

| Suitable For | Brands with internal design and engineering teams | Brands lacking R&D and wanting faster launch |

| Advantages | High production control, focus on branding and sales | Minimal R&D cost, rapid market entry, ready-to-label products |

OEM CNC vs ODM CNC in Global Machining Supply

When selecting a precision machining partner, the difference between OEM CNC service and ODM CNC turning service directly impacts development time, cost, and product ownership. With OEM CNC machine service, the customer defines tolerances, 3D files, materials, and inspection criteria, while the manufacturer executes multi-axis turning, milling, heat treatment, plating, and final QC. This route is ideal for aerospace fittings, hydraulic valves, automotive turned inserts, and stainless steel connectors requiring strict dimensional control.

Meanwhile, ODM CNC turning service enables faster commercialization by allowing the manufacturer to design the product architecture, validate prototypes, and deliver brand-ready components. Clients simply apply their label without investing in engineering teams, CAD modeling, tooling, or verification testing. This method accelerates product release in pneumatic joints, brass fittings, industrial connectors, and high-precision hardware where speed-to-market is crucial.

Ultimately, OEM secures full design control and IP ownership, while ODM offers a turnkey path with reduced technical burden. Whether you choose OEM CNC machining for exact drawing compliance or ODM CNC solutions for rapid deployment, partnering with a certified multi-axis turning provider ensures component reliability, cost efficiency, and scalable production for international markets.

How to Place an OEM CNC machining Service or OEM CNC Turning Order

In modern global manufacturing, understanding how to efficiently place an OEM CNC service or ODM CNC turning service order is essential for companies sourcing hydraulic fittings, bulkhead connectors, and precision metal components. While OEM CNC services give full control over tolerances, dimensions, and material specifications, ODM CNC turning allows for rapid product development with minimal R&D investment. Below is a clear comparison of the step-by-step process for both services, helping buyers make informed decisions and streamline procurement from certified CNC suppliers.

| Step | OEM CNC machining Service | ODM CNC Turning Service |

|---|---|---|

| Initial Requirements | Provide detailed technical drawings or 3D CAD files with dimensions, tolerances, materials, plating, and assembly instructions. | Provide general concept, functional requirements, or prototype idea; detailed CAD drawings are optional. |

| Quotation & Approval | Supplier provides detailed quotation including material cost, machining time, plating, heat treatment, and shipping. Buyer approves before production. | Supplier designs product architecture, estimates cost and lead time, and proposes initial prototype plan. Buyer approves concept. |

| Prototype / Sample | Optional small-batch sample to verify tolerances, fits, and surface finish. | Supplier produces prototype or sample batch for functional testing and design validation. Buyer can request adjustments. |

| Production | Full-scale multi-axis CNC turning, milling, heat treatment, plating, and quality inspection based on approved drawings. | Full-scale production after prototype approval, including CNC turning, plating, heat treatment, and QC. Supplier manages design compliance. |

| Quality Control | In-process inspection and final QC reports provided; full control over tolerances and specifications. | Supplier ensures prototype meets functional requirements; final QC ensures brand-ready components. |

| Delivery | Shipped with material traceability, compliance certificates, and international shipping documentation. | Shipped with traceability and ready-to-use for brand labeling; reduces technical burden for buyer. |

| Best Use | High-precision components requiring strict drawing compliance, critical hydraulic fittings, aerospace and automotive parts. | Fast commercialization, low-R&D investment, pneumatic joints, brass fittings, industrial connectors, and custom metal components |

Welcome to contact us when you need help.