Blind threaded holes are widely used in custom CNC turned parts, especially when component structure or sealing requirements limit through-hole designs. However, blind threads introduce higher risk and cost compared to through threads if not properly designed or processed.

Many buyers specify blind threads without fully considering thread depth, bottom clearance, and material behavior during tapping. These factors can directly affect machining stability, tool life, and final assembly quality. From a CNC turning manufacturer’s perspective, choosing between blind threads and through threads is not only a design decision, but also a cost and reliability decision.

This article compares blind threads and through threads in CNC turning, explains common machining problems—including small hole challenges—and shares practical design considerations based on real production experience.

What Is a Blind Thread in CNC Turned Parts?

A blind thread refers to an internal thread that does not pass completely through a part. The hole has a closed bottom, which limits chip evacuation during tapping and requires precise depth control.

Blind threads are commonly used in:

-

Hydraulic and pneumatic fittings

-

Valve components

-

Sealing-related CNC turned parts

-

Compact mechanical assemblies

While functionally necessary, blind threads are more sensitive to machining parameters than through threads.

Blind Thread vs Through Thread: Key Differences

| Item | Blind Thread | Through Thread |

|---|---|---|

| Machining difficulty | Higher | Lower |

| Risk of tap breakage | High | Low |

| Chip evacuation | Limited | Easy |

| Depth control | Critical | Less critical |

| Machining cost | Higher | Lower |

| Production stability | Lower | Higher |

Through threads are preferred whenever design allows, due to easier machining and better production stability.

Common Problems with Blind Threaded Holes in CNC Machining

In daily CNC turning production, blind threads often cause the following issues:

-

Broken taps due to poor chip evacuation

-

Insufficient effective thread depth, causing weak fastening

-

Bottom interference, preventing full bolt engagement

-

Inconsistent thread quality in batch production

For internal diameters smaller than 8 mm, it becomes impossible to perform CNC turning with standard turning tools because the tool holder and cutter do not have enough space to reach deep inside the hole.

Additionally, small internal holes make chip evacuation difficult, increasing the risk of tool breakage, higher costs, and slower processing speed.

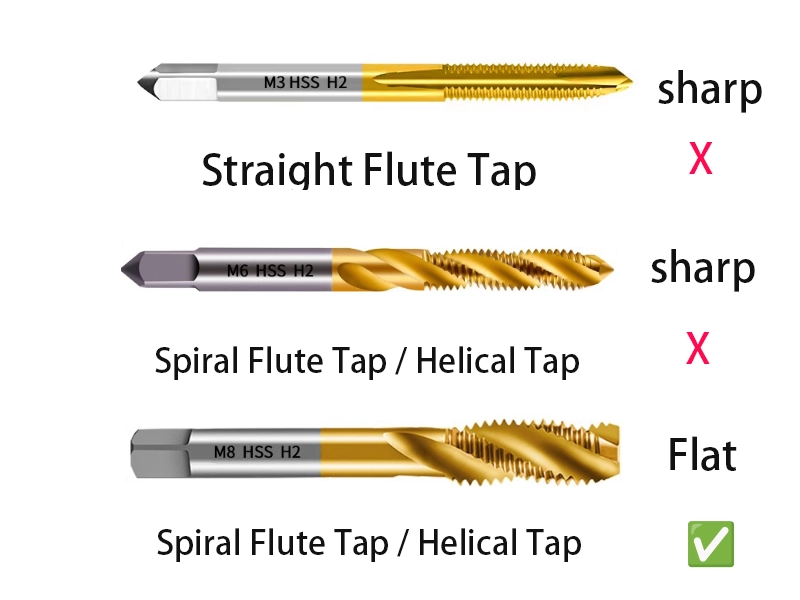

When using spiral (helical) taps for blind holes, it is important to ensure that the hole bottom is flat to maximize effective thread length. If the bottom is too pointed, the effective thread may not meet the customer’s drawing requirements.

Why Blind Threads Increase CNC Machining Cost

Blind threads require:

-

Slower tapping speeds for small holes

-

Frequent tool replacement due to breakage risk

-

Careful bottom preparation to meet drawing specifications

-

Additional inspection and potential rework

As a result, blind-threaded holes directly increase machining cost and may slow production, even when the geometry seems simple.

Blind Thread Depth and Tolerance Considerations

Thread depth is critical, especially for small-diameter blind holes. Key considerations include:

-

Maintaining sufficient effective thread engagement

-

Ensuring the bottom is flat and not pointed

-

Avoiding overly tight tolerances that increase tool breakage risk

-

Using spiral taps to improve chip evacuation and reduce breakage

Proper attention to these points helps maintain quality and consistency, even for challenging small blind holes.

Material Challenges When Machining Blind Threads

Based on our production experience:

-

Iron and stainless steel are the most common materials for blind threads.

-

Small holes (≤8–10 mm) are particularly challenging due to tool accessibility and chip evacuation.

-

Spiral taps are preferred over straight-flute taps for these cases.

-

Vertical alignment and bottom flatness must be carefully controlled to ensure thread quality.

Spiral Tap vs Straight Flute Tap Comparison

| Feature | Straight Flute Tap | Spiral Flute Tap |

|---|---|---|

| Chip evacuation | Poor in blind holes | Efficient, chips flow upward |

| Risk of tap breakage | High | Lower |

| Suitable hole depth | Limited | Suitable for small blind holes |

| Machining speed | Slower | Faster |

| Typical applications | Shallow holes, general threading | Blind holes, tight tolerances |

Design Tips to Reduce Risk When Using Blind Threads

-

Avoid blind threads if through threads are possible (design permitting)

-

Maintain sufficient thread depth margin

-

Ensure Spiral Flute Tap top is fat to meet effective thread requirements

-

Specify realistic tolerances

-

Confirm material machinability before production

-

For small blind holes, prefer spiral taps over straight-flute taps

Early design optimization reduces production risk and overall cost.

How We Control Blind Thread Quality in CNC Turning Production

In our production:

-

Tapping parameters are optimized based on material and hole size

-

Depth and bottom flatness are strictly controlled

-

In-process inspection of thread quality and depth is performed

-

Tool conditions are monitored to avoid sudden tap breakage

These measures ensure stable production and consistent part quality.

Application Examples

We mainly serve customers in:

-

Pneumatic fittings

-

Hydraulic fittings

-

Gas pipe fittings

-

Oil pipeline fittings

These examples highlight that our recommendations are based on real production experience, not theory.

Conclusion

Blind threads are sometimes necessary, but they require careful attention, especially for small diameters (<8 mm) in iron or stainless steel. Using spiral taps, controlling depth and bottom flatness, and ensuring vertical alignment can ensure stable, cost-effective production without affecting lead time. Proper design choices at the early stage significantly reduce machining risk and improve overall quality. If you’re looking for high-quality blind thread machining in iron or stainless steel, our experienced team can help. We specialize in pneumatic, hydraulic, gas, and oil pipe fittings, ensuring fast lead times, precise threads, and cost-effective solutions.