In the world of high-stakes manufacturing—where a fraction of a millimeter can make or break an entire system—buyers don’t have time for guesswork. So, what is CNC turning? It’s not just machines spinning metal. It’s precision on autopilot, churning out parts so tight in tolerance they’d put your tape measure to shame.

Now picture this: an aerospace engineer staring down a deadline, hunting for thousands of stainless steel components with no wiggle room for error. Manual lathes aren’t gonna cut it (literally). Enter CNC turning—fast, repeatable, and ridiculously accurate. Perfect parts at scale? That’s the dream.

It’s less about bells and whistles and more about getting dependable quality—every time you hit order.

Key Insights on What is CNC Turning: A Comprehensive Overview

- Definition: CNC turning is a manufacturing process that uses computer-controlled lathes to produce precision parts with tight tolerances.

- Material Versatility: CNC turning accommodates a wide range of materials, including aluminum alloys and titanium grades, each tailored for specific applications.

- Precision and Efficiency: This automated process ensures high repeatability and dimensional accuracy, making it essential for industries like aerospace and medical devices.

- Comparison with Traditional Methods: Unlike manual lathes, CNC turning minimizes human error and enhances production speed and quality through advanced machine capabilities.

- Post-Production Quality Checks: CMM inspection and other testing methods are crucial for validating the quality and precision of CNC-turned parts.

CNC Turning: An Overview of the Process

This guide breaks down how CNC turning works, what materials it handles, and why it’s so vital to modern manufacturing.

The Role of CNC Lathes in Modern Manufacturing

CNC lathes are everywhere now, from aerospace to auto shops. Why? Because they crank out precision parts like clockwork.

• Automation rules the floor — once programmed, these machines run solo for hours, even overnight.

• High-volume runs? No sweat. Their repeatability makes them perfect for mass production without quality dips.

• Complex shapes that used to take days now come out with micrometer-level accuracy thanks to advanced precision machining features.

With demand rising for tighter tolerances and quicker turnarounds, CNC lathes are no longer optional — they’re essential tools across all kinds of industrial applications.

Understanding Materials: From Aluminum Alloys to Titanium Grades

Not every metal plays nice on a lathe — some cut cleanly, others fight back hard.

🟢 Soft metals like aluminum alloys machine fast and cool but can gum up if speeds aren’t dialed right.

🟡 Mid-hardness picks such as brass alloys offer a sweet spot between cost and finish quality.

🔴 Tough customers like certain titanium grades resist wear but require slower feeds and specialized tooling.

| Material Type | Machinability Rating | Common Use Case | Tool Wear Rate |

|---|---|---|---|

| Aluminum 6061 | High | Aerospace brackets | Low |

| Brass C360 | Very High | Valves & fittings | Very Low |

| Stainless Steel 304 | Medium | Food-grade equipment | Moderate |

| titanum | Low | Medical implants | High |

Choosing the right material means balancing strength, weight, corrosion resistance — and yes, how well it behaves during metalworking.

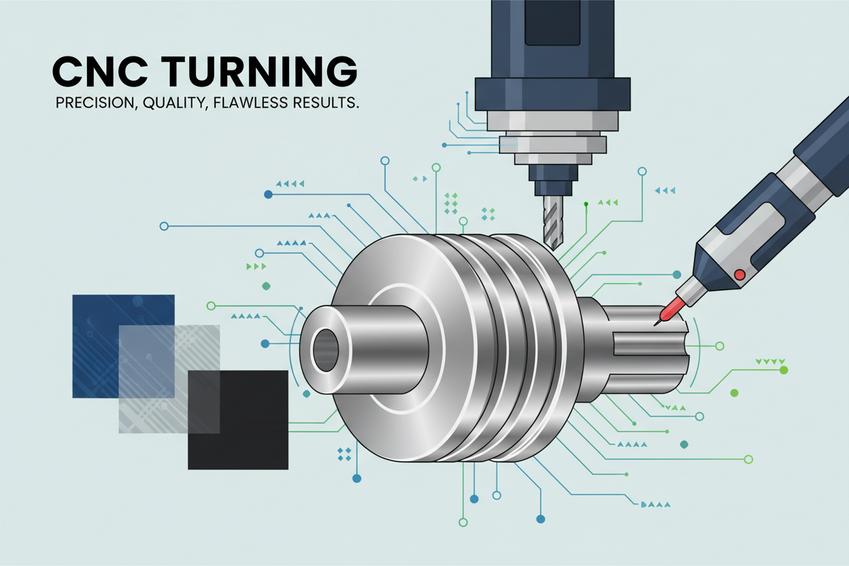

How CNC Turning Works: The Mechanism Behind Precision

Getting into the nuts and bolts of this process shows just how clever these machines really are.

Step 1 – A cylindrical workpiece is clamped into a rotating chuck on the lathe’s spindle.

Step 2 – The cutting tool moves along linear axes while the workpiece spins at high speed.

Step 3 – Based on pre-written instructions using G-code, tools remove material layer by layer following exact paths from a CAD file.

Step 4 – Adjustments to parameters like feed rate, depth of cut, or coolant flow help fine-tune surface finish or prevent overheating.

Thanks to tight control over each motion axis via servos and encoders — plus software integration with CAM programs — modern CNC turning processes deliver unmatched consistency and efficiency even at micro-scale tolerances.

And that’s where “what is cnc turning” comes full circle: it’s not just about spinning metal; it’s about combining digital brains with mechanical brawn to sculpt perfection every time.

Top 4 Benefits of CNC Turning for Precision Manufacturing

Precision matters, and when it comes to what is cnc turning, the benefits go far beyond just shaping metal.

Tight Tolerances: Delivering Precision in Every Component

- Micron-level tolerances are no joke—they’re what make or break high-performance parts.

- With CNC turning, you can repeatedly hit exact specifications, even on complex geometries.

- Why does that matter? Because even a tiny deviation can ruin an entire assembly.

Imagine producing thousands of custom components, like aerospace bushings or hydraulic shafts, where every single one has to be spot-on. That’s where tight precision and strict quality control come into play. CNC machines don’t guess—they calculate down to the micron, ensuring each part fits perfectly without rework.

And when customers ask “what is cnc turning” really good for? You show them a shaft that hits ±0.002mm on every run.

The Advantage of Automated Turning: Efficiency and Consistency

CNC automation isn’t just about speed—it’s about doing it right every time:

- 🔁 Repeatability: Once a program is set, the machine won’t drift from its path.

- ⚙️ Efficiency: High-speed spindles + optimized toolpaths = shorter cycle times.

- 🧠 Less human error = fewer scrap parts and more uptime.

- 💡 Smart sensors monitor tool wear in real-time for proactive maintenance.

Grouped Benefits: • For high-volume runs—like electrical connectors, pipe fittings, or threaded inserts—you get unmatched consistency across batches.

• It boosts overall shop floor productivity, freeing up skilled machinists to focus on programming and inspection instead of babysitting machines.

• More than anything else, automated turning slashes lead times while keeping quality locked in—no surprises at delivery.

No wonder shops like yuhuan hongqian are dominating their niche markets with this approach.

Material Certification: Ensuring Quality with Each Batch

Every batch starts with trusted raw stuff—and it better be traceable:

• Certified materials like aerospace-grade titanium or hardened carbon steel aren’t optional; they’re expected. • Suppliers must meet rigorous industry specs before materials even touch the lathe. • Full traceability ensures each bar stock links back to its origin point—down to heat number and mill certs.

That’s how you meet compliance standards without breaking a sweat—and why certified material sourcing is central to answering “what is cnc turning” at a professional level.

Shortcuts here? Not worth the risk when your reputation rides on consistent mechanical properties across all your turned parts.

Dimensional Accuracy: Meeting Industry Standards with CNC

Dimensional accuracy isn’t just buzz—it’s the bedrock of modern machining standards across industries like automotive, medical devices, and defense systems. When engineers say they need parts within ±0.005mm tolerance over multiple axes, they mean it—and CNC turning delivers that kind of pinpoint precision daily through advanced tooling and closed-loop feedback systems.

According to a 2024 report by Global Manufacturing Metrics Group, over 82% of OEM buyers rank dimensional accuracy as their top requirement when sourcing machined components. That stat alone tells you how vital this feature is in competitive manufacturing environments where failure isn’t an option.

So next time someone asks “what is cnc turning” used for at scale? Tell them it’s how modern industries build trust—one flawless measurement at a time.

CNC Turning vs. Traditional Methods: The Key Differences

Let’s break down how modern machining like CNC turning stacks up against old-school techniques—and why it matters for your bottom line.

CNC Turning vs. Manual Lathes

You can think of manual lathes as the analog version of machining—lots of knobs, levers, and human finesse involved. In contrast, CNC turning is more like programming a robot to carve with laser precision.

- Manual lathes demand serious operator skill, while CNC systems rely on pre-coded instructions.

- You’ll see way better repeatability with CNC; every part comes out identical.

- Setup time? With CNCs, it’s slashed dramatically—manual machines need constant tweaks.

- Human error is common in manual work; automation reduces mistakes and boosts consistency.

- Want tighter tolerances? CNC has you covered with unmatched precision.

Now toss in cost-effectiveness over long production runs—CNC wins hands down. Sure, the upfront investment might sting a bit, but when you’re pushing out thousands of parts with minimal scrap? That’s where you save.

If you’re wondering what is cnc turning, it’s essentially automating the cutting process using computer controls instead of hand-operated tools—faster, smarter, and scalable.

And if you’re still rocking manual setups for high-volume jobs… yikes. Might be time to rethink that strategy.

Benefits of Multi-Axis Machines Over Conventional Techniques

When we talk about multi-axis versus traditional single-axis turning tools, the difference isn’t just technical—it’s transformational.

✔️ Multi-axis machining handles intricate cuts from multiple angles without moving the part between machines.

✔️ It enables shaping highly complex geometries, which would otherwise take forever or be flat-out impossible using basic tools.

✔️ With fewer repositionings required, you get massive gains in both speed and accuracy—hello reduced setups!

✔️ The result? Cleaner finishes and tighter tolerances across the board thanks to superior control over tool paths.

Here’s a quick side-by-side snapshot:

| Feature | Single-Axis Turning | Multi-Axis Machining | Efficiency Gain |

|---|---|---|---|

| Tool Movement | Linear only | Rotational & linear | High |

| Setup Changes Required | Frequent | Minimal | Major |

| Part Complexity Capability | Limited | Very High | Significant |

| Surface Finish Quality | Moderate | Excellent | Noticeable |

This all means better output with less downtime—and that spells real productivity gains for shops looking to scale fast without sacrificing quality.

One brand that’s been quietly crushing it in this space? yuhuan hongqian. Their multi-axis solutions are built for serious manufacturers who aren’t messing around with outdated tech anymore.

So next time someone asks what is cnc turning, tell them it’s not just about spinning metal—it’s about doing it smarter, faster, and cleaner than ever before.

How CNC Turning Enhances Product Quality and Precision

CNC turning isn’t just about shaping metal—it’s about nailing the details that make parts flawless, functional, and factory-ready.

Precision Machining Techniques: The Art of Detail

- CNC turning is all about repeatable precision. Once the program’s locked, every part comes out like a twin.

- Super tight tolerances? Easy. We’re talking down to microns—no room for guesswork.

- With high-end tooling, even complex profiles stay crisp with no chatter marks.

- CAD/CAM software ensures the design matches output pixel for pixel.

- Multi-axis machining brings curves and angles into one smooth operation.

- Micro-sized features? That’s where micro-machining steps up, especially for medical-grade components.

You can’t fake accuracy when it comes to aerospace or surgical tools. CNC lathe systems thrive on consistency, making sure your specs are more than just wishful thinking.

Surface Finishes: Choosing the Right Coating for Each Application

• Want corrosion resistance? Go with anodizing—especially for aluminum parts that need extra grit without losing their shine.

• For stainless steel, passivation strips away contaminants and makes it tougher against rust without adding bulk.

• If looks matter as much as performance, powder coating gives color options with durability baked right in.

Smoothness isn’t just visual—it affects how parts move together under pressure. A polished surface reduces wear; a rougher one might help grip or adhesion depending on use case.

Each finish also changes how light reflects off your part—important when appearance counts as much as functionality.

CMM Inspection: Validating Quality in CNC Parts Production

- Every turned part gets measured using a CMM—a tool that doesn’t blink when checking tolerances.

- It scans across surfaces to verify each dimension against the digital model.

- If something’s off by even a hair, it flags it before shipping ever happens.

A solid inspection process is key when you’re working with tight deadlines and tighter specs. Dimensional checks aren’t just box-ticking—they’re how you prove quality under pressure.

Using real-time feedback from these machines helps adjust future runs too—keeping scrap low and confidence high across batches of precision components made via CNC turning.

By combining sharp machining skills with smart finishing choices and spot-on inspections, manufacturers can answer the question “what is cnc turning” not just technically—but practically through flawless results every time.

Investing in CNC Turning: What You Should Consider

Picking the right tools and knowing where they shine is half the battle in machining.

Equipment Choices: Swiss-Type Lathes vs. Turning Centers

Choosing between Swiss-type lathes and turning centers depends on your production goals:

- Swiss-type lathes

- Best for tiny, complex parts like screws or surgical pins.

- Feature a sliding headstock and guide bushing for ultra-tight tolerances.

- Often used in high-volume runs due to their speed and precision.

- Turning centers

- Offer more flexibility with larger workpieces.

- Typically come with multiple axes and live tooling options.

- Great for jobs that require milling, drilling, or tapping alongside turning.

Both types fall under advanced CNC machinery, but each suits a different kind of job shop or factory floor. If you’re producing watch components or catheter tips, go Swiss. If you’re cranking out automotive hubs or custom flanges, a robust turning center will serve you better.

Still unsure which one fits your workflow? That’s where brands like yuhuan hongqian step in—offering tailored advice based on real-world machining needs.

Industry Applications: Which Sectors Benefit Most from CNC Turning?

When people ask “what is cnc turning,” it helps to break it down into who actually needs it—and why:

• In the aerospace industry, tolerance isn’t just important—it’s life-or-death. Jet engine rings and turbine shafts rely on exact dimensions that only CNC can deliver.

• The demand for miniaturized accuracy makes CNC turning essential in crafting tight-tolerance parts for everything from pacemaker housings to orthopedic screws in the medical devices field.

• Over in the world of speed and torque, automotive components like drive shafts and pistons are mass-produced using high-efficiency lathe setups.

• Think about your phone or laptop—the guts inside come from ultra-precise machines used widely across electronics manufacturing lines worldwide.

• For tough environments like deep-sea drilling or fracking rigs, the oil industry banks on durable turned parts that can withstand pressure—literally—in the oil and gas sector.

• And if you’re prototyping something brand-new? Fast-turnaround shops lean on CNC turning because of its repeatability during quick iteration cycles—ideal for both small-batch production and scaling up later.

No matter how you slice it—or turn it—this tech finds its way into nearly every modern product we touch daily.

FAQs about What Is CNC Turning

What is CNC turning and why does it matter for bulk part orders?

CNC turning shapes materials like aluminum alloys, stainless steel, or titanium grades into shafts components, bushings elements, and fittings accessories with uncanny precision. Using CNC lathes or multi-axis machines, each cut is controlled to achieve tight tolerances—so large-volume runs arrive uniform and ready for assembly without frustrating fit issues.

How does material choice influence performance in different industries?

Selecting the right metal steers a project’s fate:

- Aluminum alloys – lightweight yet strong for electronics manufacturing connectors devices.

- Carbon steel – rugged endurance for automotive industry fasteners hardware.

- Brass alloys – subtle corrosion resistance valued in medical devices fittings accessories.

It’s not just strength; it’s how each reacts under wear, heat, or exposure in aerospace sector missions or oil and gas installations.

Why are tight tolerances so important when ordering thousands of parts?

Micron-level close fits mean that every shaft component behaves predictably during assembly—no jammed bushings elements or misaligned connectors devices to slow production lines in high-demand markets like medical devices or aerospace sector applications where precision machining isn’t a luxury but survival.

Which surface finishes can be applied during production runs?

Finish selection blends function with style: anodized coating shields aluminum from corrosion; powder coating builds durability against outdoor conditions; passivation process cleans stainless steel until its shine matches its longevity; black oxide finish adds understated protection on carbon steel while electropolishing service turns titanium grades mirror-smooth for demanding environments.

How do inspections ensure quality before accepting a supplier’s offer?

CMM inspection checks dimensional accuracy batch after batch; optical comparator magnifies edge profiles to catch subtle flaws; surface roughness testing feels out imperfections invisible to the eye; material certification confirms your brass alloys meet strict standards—and together these safeguards make sure even massive orders land within promised specifications without nasty surprises at installation time.