The operation steps of CNC machine tool parts usually include the following links:

First, boot preparation and machine back to zero

Boot Up:

Start the main power supply of the CNC machine tool to ensure that the machine tool and the CNC system are powered on normally.

Machine reset:

Manually operate each axis to return to the origin of the machine, establish the machine coordinate system, and provide a reference position for subsequent processing.

Second, workpiece clamping and alignment

Workpiece cleaning and clamping:

Clean the surface of the piece to ensure that there is no oil, iron filings and dust.

The workpiece is firmly clamped on the machine with the appropriate fixture to ensure accurate positioning and reliable clamping.

Job alignment:

By using manual incremental movement, continuous movement or hand wheel to move the machine, the workpiece alignment operation is carried out to ensure that the workpiece coordinate system is consistent with the machine coordinate system.

Third, tool preparation and tool matching

Tool selection and installation:

Select the appropriate tool according to the machining requirements and install it on the spindle of the machine tool.

Knife operation:

Use tool setting tools (such as edge finder, tool setting instrument, etc.) to set the tool and determine the exact position of the tool in the workpiece coordinate system.

Input tool parameters, offset amount, various compensation values, etc., to ensure that the tool can cut according to the predetermined path.

Fourth, program input and debugging

Program input:

The written NC machining program is entered into the CNC unit through the input device (such as keyboard, floppy disk, communication interface, etc.).

Program debugging:

Before the formal machining, the program is simulated or test cutting operation to check the correctness and feasibility of the program.

If program errors or processing problems are found, they should be modified and adjusted in time.

Fifth, automatic processing and monitoring

Start automatic processing:

After confirming that the program is correct, the automatic processing mode is started, and the machine tool is cut according to the predetermined program.

Process monitoring:

In the process of processing, real-time monitoring of the running state of the machine tool and processing quality.

Pay attention to observe the tool trajectory, cutting force, machine tool vibration and other parameters to ensure that the processing process is stable and reliable.

Sixth, processing and testing

Processing completed:

When the program is finished, the machine will automatically stop processing.

Turn off the machine power and remove the finished parts.

Quality inspection:

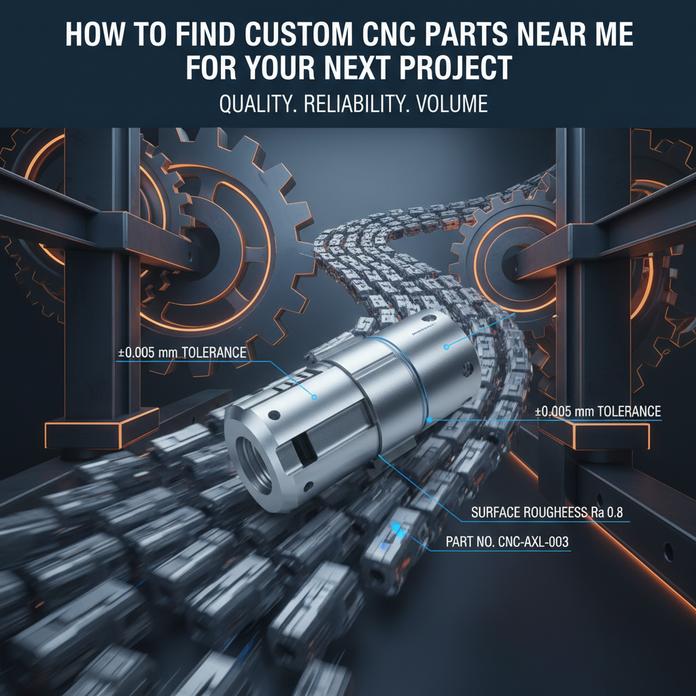

Quality inspection of the finished parts, including dimensional accuracy, shape accuracy, surface roughness, etc.

If quality problems are found, the reasons should be analyzed and corresponding measures should be taken to improve.

Seventh, clean the site and machine maintenance

Cleaning and processing site:

Clean the table, jig, tool and other parts of the iron filings, oil and other debris.

Keep the processing site clean and orderly.

Machine maintenance:

Perform routine maintenance and maintenance of machine tools, such as cleaning and lubrication, fastening screws, checking electrical systems, etc.

Ensure that the machine is in good working condition for a long time.

To sum up, the operation steps of CNC machine tool parts are a complex and delicate process that requires operators to have rich experience and professional knowledge. Through strict startup preparation, workpiece clamping and alignment, tool preparation and tool alignment, program input and debugging, automatic processing and monitoring, and processing completion and testing, we can ensure that the parts that meet the requirements are processed.