Bulkhead frame fittings is one standard cnc turning parts belong to carbon steel truck parts .it is one type of bulhead pipe fitting belong to automobile area fittings.

It main widely used in america market and latin america market .

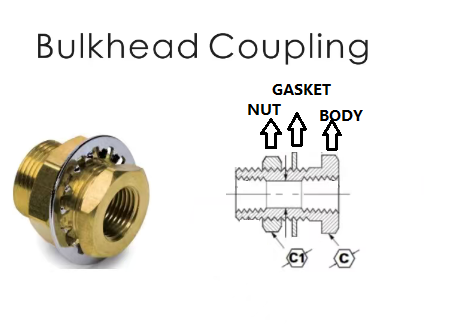

Bulkhead fitting are used when connecting a tube or hose through a frame rail or other barrier. Other industry terms used for bulkhead are Terminal Bolt, Anchor Fitting, Frame Coupling, and Clamping Studs. .

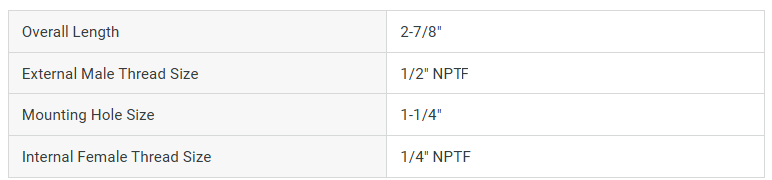

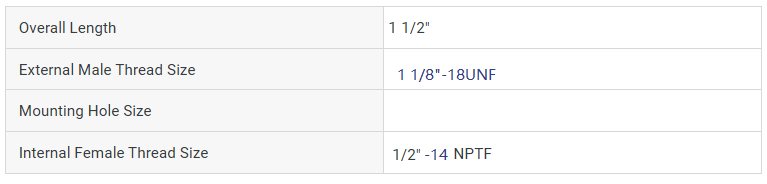

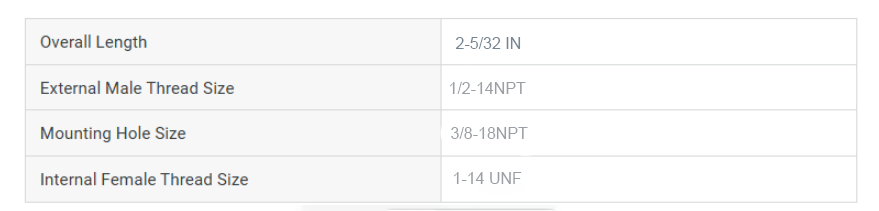

Here make up several bulkhead frame nipple and remark specific size .

Yuhuan hongqian machinery co.,ltd is professional supply iron ,zinc plated bulkhead/anchor/Frame couplings many years . we are a professional cnc turning parts company with 70 sets cnc machining .

It made of body(thread pipe fittings) , hex nut , and gasket.

Carbon steel is one of the best material choices for bulkhead fittings, especially in automotive and heavy-duty truck applications. Its superior hardness, tensile strength, and impact resistance allow carbon steel bulkhead fittings to withstand continuous vibration, high pressure, and harsh road environments without deformation or thread wear. This ensures long-term sealing performance in fuel lines, hydraulic systems, brake assemblies, and chassis-mounted fluid transfer points.

Additionally, carbon steel offers a significant cost advantage compared to brass or stainless steel. It delivers high mechanical strength at a more economical price, making it ideal for large-scale manufacturing and fleet maintenance where durability and budget efficiency are equally important. For users seeking reliable performance, long service life, and excellent value, carbon steel bulkhead fittings remain one of the most practical and cost-effective solutions in the automotive industry.

In summary, carbon steel bulkhead fittings remain one of the most reliable and cost-effective solutions for automotive and heavy-duty truck systems. With strong hardness, excellent pressure resistance, and long-term stability under vibration, they guarantee secure sealing performance in fuel lines, hydraulic circuits, brake assemblies, and chassis-mounted fluid transfer points. Compared with brass or stainless steel, carbon steel offers the same mechanical strength at a significantly lower cost, providing clear pricing advantages for large-volume manufacturing and fleet maintenance.