Ever tried juggling flaming torches while riding a unicycle on a tightrope? That’s about what it feels like when you’re sourcing stainless steel pipe fittings manufacturers for large-scale industrial ops. One misstep—and boom—delays, compliance headaches, and budgets going up in smoke.

In the words of Li Chengwei, senior engineer at Yuhuan Hongqian: “Choosing the right supplier isn’t just procurement—it’s protection.” The 2024 China Industrial Piping Report backs him up—over 68% of plant failures traced back to substandard fittings or inconsistent specs. Yikes.

You’re not buying trinkets here; you’re building systems that move oil, steam, chemicals—or sometimes yogurt—through miles of high-pressure chaos. And you need a partner who won’t ghost you mid-project or ship parts that don’t fit.

So how do you separate the real deal from the pipe dream? Stick around—we’re getting into it.

Key Points for Choosing Stainless Steel Pipe Fittings Manufacturers

→ Material Quality: Choose suppliers that offer high-quality materials like 316 and duplex stainless steel for enhanced corrosion resistance and durability in harsh environments.

→ Certifications: Ensure manufacturers adhere to ASTM A403 and ASME B16.9 standards to guarantee reliable and accurate fittings that meet industry regulations.

➔ Fitting Types: Look for essential fitting variants such as elbows, tees, reducers, and couplings, which are crucial for designing efficient piping systems.

→ Size Range: Pay attention to the availability of common sizes like 2-inch and 4-inch fittings, which are essential for medium and large-scale systems.

➔ Connection Types: Consider the most appropriate connection methods—whether butt weld, threaded, or flanged—based on your project’s specific needs and ease of disassembly.

→ Application Suitability: Verify that the manufacturer specializes in your required application, such as plumbing, chemical processing, or food production, to ensure their products meet the necessary standards for durability and safety.

Understanding the Basics of Stainless Steel Pipe Fittings

A quick dive into the nuts and bolts of stainless steel pipe fittings—types, uses, shapes, and how they connect.

Types of Stainless Steel: 304 vs. 316 vs. 316L

- 304 stainless steel is your go-to all-rounder—solid corrosion resistance, easy to fabricate, and cost-effective.

- 316 stainless steel adds a dash of molybdenum, boosting its defense against chlorides and salty environments like marine setups.

- If welding’s in the picture, 316L stainless steel steps up with low carbon content to reduce carbide precipitation during high-heat applications.

In short:

• Go with 304 if you need general-purpose value.

• Choose 316 when corrosion gets serious.

• Opt for 316L when welds matter most.

No surprise that top-tier stainless steel pipe fittings manufacturers rely heavily on these three grades to cover everything from food-grade installs to offshore rigs.

Essential Fitting Variants: Elbows, Tees, Reducers, and More

There’s a whole world beyond just pipes—and here’s where it gets interesting:

- Elbows bend flow around tight corners without losing pressure or speed.

- Tees split or combine flow paths in T-shaped junctions—ideal when branching off another line.

- Reducers, both concentric and eccentric types, help transition between different pipe sizes smoothly without turbulence issues.

- Then we’ve got: • Straight and reducing couplings • End-sealing caps • Four-way connectors like crosses • Detachable joints via threaded or socket-welded unions • Short lengths called threaded or plain-end pipe nipples

Each type serves a specific purpose in fluid control systems—and top stainless steel pipe fittings manufacturers like yuuhuan hongqian keep their catalog stacked with every variation imaginable.

Common Applications for Stainless Steel Pipe Fittings

Let’s break it down by industry:

■ In the food & beverage world, hygiene comes first—so smooth-surfaced fittings made from high-grade materials are essential.

■ In chemical plants and refineries? Corrosion resistance is king. That’s where high-nickel alloys shine alongside classic grades like 316.

■ The oil & gas sector demands durability under pressure—literally—and temperature swings make material choice critical.

■ Water treatment facilities rely on longevity; no one wants leaks in potable water lines after just a few years.

■ HVAC systems use these fittings behind walls and ceilings—you need something that lasts decades without fail.

From dairy pipelines to pharmaceutical cleanrooms, these components are everywhere—and trusted names among stainless steel pipe fittings manufacturers know exactly how to meet those diverse needs.

According to Frost & Sullivan’s Q2 Industrial Materials Outlook Report published April 2024: “Global demand for hygienic-grade stainless components has surged by over 12%, driven primarily by stricter sanitation codes across Southeast Asia.”

Popular Connection Types: Butt Weld vs. Threaded vs. Flanged

Short takes on connection styles:

Butt welds? Seamless joins with no internal ridges—they’re ideal when strength matters most and you want zero leakage risk over time.

Threaded connections use either standard NPT or BSPT threading styles—great when disassembly might be needed later but not ideal under high vibration conditions.

Flanged connections add bulk but offer unmatched ease during maintenance; bolted together using gaskets between faces ensures secure sealing even under extreme pressures.

Other options include:

- Socket welds—for semi-permanent installs

- Compression fittings—for quick fixes

- Gasket-supported flanges—for heavy-duty industrial jobs

Smart design means matching the right connection method to your system’s expectations—and reliable stainless steel pipe fittings manufacturers will always guide clients toward what works best based on pressure ratings, fluid types, and installation preferences.

Key Factors When Choosing Stainless Steel Pipe Fittings Manufacturers

Knowing what to look for in stainless steel pipe fittings manufacturers makes all the difference when you’re sourcing for durability, compliance, and performance.

Evaluating Manufacturer Certifications: ASTM A403 and ASME B16.9 Standards

| Certification | Governing Body | Scope of Standard | Application Area |

|---|---|---|---|

| ASTM A403 | ASTM International | Chemical & mechanical properties | Welded austenitic fittings |

| ASME B16.9 | ASME | Dimensional tolerances | Factory-made wrought fittings |

✅ ASTM A403 certification ensures the material meets strict quality standards, including corrosion resistance and tensile strength—must-haves when dealing with industrial-grade stainless systems.

💡 Meanwhile, ASME B16.9 covers the shape, wall thickness, and radius of elbows, tees, and reducers—basically making sure your fitting won’t throw off your whole layout because of slight dimensional errors.

✔️ When choosing a pipe fitting manufacturer, always confirm both certifications are clearly stated on their data sheets or mill test reports. If they aren’t? That’s a red flag waving hard.

Assessing Size Range: Why 2 Inch and 4 Inch Fittings Matter

- 2 inch fittings

- Ideal for moderate flow applications

- Commonly used in HVAC systems or mid-scale processing lines

- 4 inch fittings

- Handle higher volumes without pressure drops

- Found in chemical plants, water treatment setups

Both sizes hit that sweet spot between compactness and capacity. These dimensions are workhorses across industries—too small restricts flow; too large complicates installation and costs more.

When assessing a supplier’s catalog of pipe fitting sizes, make sure these two are well-represented with multiple pressure ratings and types (like elbows, tees). Lack of variety here might suggest limited tooling or outdated manufacturing capabilities.

Importance of Material Selection: Duplex Stainless Steel vs. Carbon Steel A234 WPB

🛠️ Material choice isn’t just about price—it’s about where you’re putting it to work.

- In corrosive environments like offshore rigs or chemical plants:

- Go with Duplex Stainless Steel

- Higher strength-to-weight ratio

- Excellent chloride stress resistance

- In non-corrosive indoor or low-pressure settings:

- Consider Carbon Steel A234 WPB

- Easier on the wallet

- Still strong enough for basic structural piping

But don’t just take a guess based on appearance—check the specs! Look at yield strength, elongation percentage, and corrosion resistance ratings before buying from any so-called expert in stainless steel pipe fittings manufacturing. One wrong call here could mean early system failure or costly retrofits down the road.

Always ask if the manufacturer offers both materials; if not, they may not be equipped to meet diverse project needs.

Top Features to Look for in a Pipe Fittings Supplier

When choosing the right supplier, it’s not just about price—it’s about performance. Here’s what sets the top-tier apart.

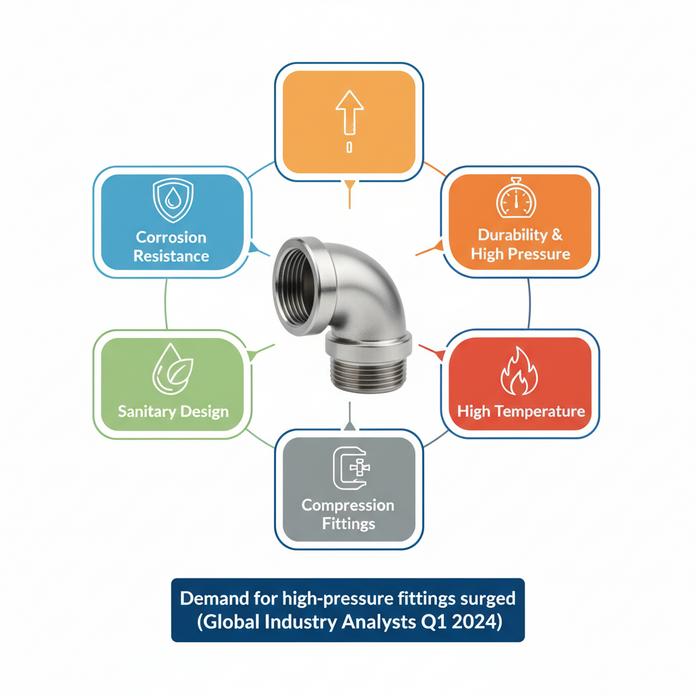

Corrosion Resistance: The Value of High Quality Stainless Steel

- 316 stainless steel resists pitting in chloride-heavy environments like marine or chemical facilities.

- Duplex grades offer higher strength and better chemical resistance, especially where acids or chlorides are present.

- A good supplier ensures fittings undergo proper passivation, forming a protective layer that enhances oxidation resistance.

- Look for suppliers who test their materials under accelerated corrosion conditions—this shows they’re not cutting corners.

- Suppliers should offer documentation on alloy grades used so you know exactly what you’re getting.

Top-performing stainless steel pipe fittings manufacturers often lead with corrosion-proof solutions that outlast cheaper alternatives by years.

Durability and High Pressure Fittings: What to Consider

You want fittings that won’t fold under pressure—literally.

- Check the material specs—316L stainless steel is a winner when it comes to both durability and weld integrity.

- Ask about burst testing results; high-quality pieces should exceed standard pressure ratings.

- Ensure long-term reliability by verifying fatigue cycle data; this reflects how well a fitting handles repeated stress.

- Don’t forget wall thickness—it plays directly into overall material strength and performance under load.

- According to Global Industry Analysts’ Q1 2024 report, demand for high-pressure fittings has surged due to stricter safety codes across oil & gas sectors.

The best pipe fittings manufacturers never compromise on these specs—they build them tough because failure isn’t an option.

Sanitary Fittings: Critical for Food Processing Applications

• Must be made from certified food grade stainless steel, typically polished to an ultra-smooth finish below Ra <0.8µm for easy cleaning.

• Should comply with FDA regulations and come with documented proof of CIP (Clean-in-Place) compatibility standards.

• Always opt for components designed with full aseptic design, minimizing crevices where bacteria could hide out or multiply fast.

If your supplier can’t meet these hygiene benchmarks, walk away—they’re not serious players in food-grade stainless pipe fitting manufacturing.

High Temperature Applications: Ensuring Fitting Longevity

Heat’s no joke when it comes to piping systems.

Some alloys break down fast at elevated temps, but not properly selected ones:

– Choose materials like 316L, which resist scaling and maintain mechanical properties past 800°C without warping or cracking. – Watch out for thermal expansion mismatches between pipes and connectors—it causes leaks over time. – Good suppliers will discuss issues like long-term exposure fatigue, as well as potential problems from repeated heating/cooling cycles (thermal cycling) which weakens joints gradually.

Only experienced pipe fitting manufacturers understand how heat stress eats away at cheap alloys over time.

Compression Fittings: Enhanced Performance Features to Seek

Step-by-step checklist when evaluating compression-style connections:

Step 1 → Inspect ferrule geometry; advanced designs improve grip strength while reducing vibration wear over time (ferrule design, anyone?).

Step 2 → Confirm reusability without leak risk; quality compression parts hold their seal even after multiple assemblies (reusability, check!).

Step 3 → Verify tolerance specs match your system’s pressure requirements; solid compression fittings provide excellent seal integrity even under fluctuating loads.

If your current pipe fitting manufacturer skimps on these details—you’ll feel it in downtime later on.

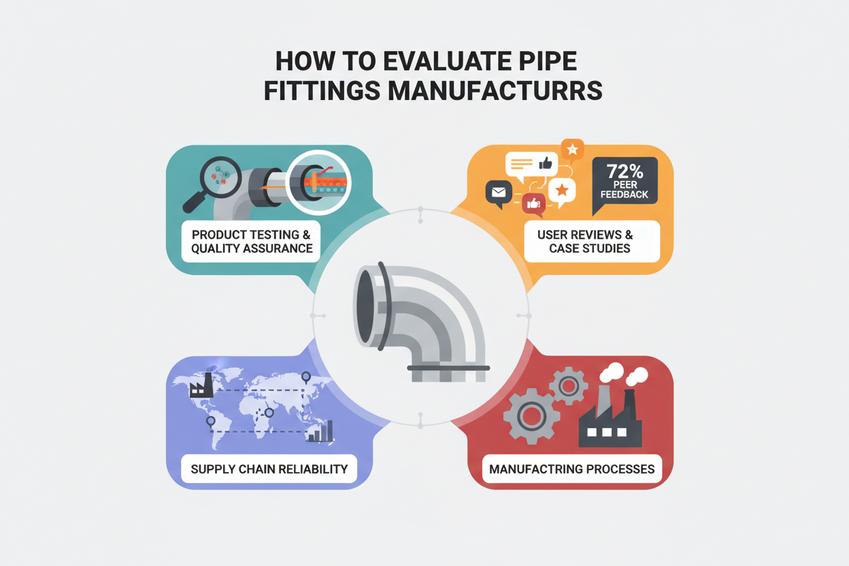

How to Evaluate the Quality of Pipe Fittings Manufacturers

A solid supplier isn’t just about price—it’s about trust, durability, and proven performance. Here’s how to spot the real pros.

Product Testing and Quality Assurance Protocols

- Material verification should always be step one—no shortcuts here. If they can’t prove what their fittings are made of, walk away.

- Check if they follow industry-standard certifications like ASTM A403 or ASME B16.9—these aren’t just acronyms, they’re your safety net.

- Look into their non-destructive testing practices—ultrasound, dye penetrant, hydrostatic pressure tests. These show who’s serious about quality.

- Ask for test reports with batch numbers—they should match your order exactly.

- Confirm whether third-party labs are involved; internal labs alone don’t cut it for critical applications.

- See if they allow factory visits or live video inspections—transparency is a green flag.

✓ Consistency in results across production runs shows tight inspection protocols, not guesswork.

If a manufacturer skimps on basic product testing, you’re gambling with leaks and downtime later on.

User Reviews and Case Studies: Insights from the Industry

Customer voices can tell you more than any spec sheet ever will.

“Over 72% of industrial buyers say peer feedback influenced their purchasing decision more than technical specs,” according to Global Industrial Trends Report 2024 by McKinsey & Co.

• Scan platforms like Thomasnet or Alibaba for verified reviews—not just stars but detailed comments on delivery timelines, weld quality, or packaging damage.

• Read through published case studies that outline how these fittings performed under stress—like high-pressure steam lines or corrosive environments.

• Pay attention to repeat clients mentioned in testimonials—it signals long-term satisfaction and strong market perception.

Short bursts of praise might look good on a homepage—but it’s consistent praise over years that indicates true industry reputation.

Supply Chain Reliability: Key to Long-Term Partnerships

A good product means nothing if it arrives late—or not at all. Here’s where supply chain muscle matters most:

| Supplier | Avg Lead Time (Days) | On-Time Delivery Rate (%) | Backorder Rate (%) |

|---|---|---|---|

| Vendor A | 12 | 98 | 1 |

| Vendor B | 20 | 85 | 5 |

| Vendor C | 8 | 92 | 3 |

| Vendor D | 15 | 88 | 7 |

• Prioritize vendors with strong inventory control systems—they’ll keep your projects moving without last-minute scrambles.

• Evaluate their global logistics network; robust logistics efficiency can make up for geographic distance when done right.

• Don’t overlook backup sourcing strategies—smart manufacturers have contingency plans baked into their supply chains to reduce risk exposure from geopolitical issues or raw material shortages.

Reliable delivery isn’t just convenient—it’s essential when coordinating multiple trades on-site or meeting inspection deadlines under tight timelines.

Analyzing Manufacturing Processes: What Makes a Difference?

Not all factories are built equal—and neither are pipe fittings.

Grouped by process impact:

➤ Forging vs Casting:

- Forged stainless steel pipe fittings typically offer tighter grain structures and higher strength.

- Cast options may be cheaper but often introduce porosity risks without proper controls.

➤ Welding Techniques:

- Look for orbital welding in automated lines—it boosts precision.

- Manual TIG welding? Fine—but only if paired with post-weld heat treatment and x-ray inspection.

➤ Finishing Touches:

- Electro-polishing improves corrosion resistance.

- Beveling accuracy affects fit-up time during installation—a small detail that saves hours later.

Smart manufacturers invest in automation not just for speed but also consistency across batches—a key marker of advanced production techniques and modernized machinery use.

The best stainless steel pipe fittings manufacturers blend old-school craftsmanship with cutting-edge tech—and let the results speak through every fitting shipped out the door.

FAQs about Stainless Steel Pipe Fittings Manufacturers

What certifications define trustworthy stainless steel pipe fittings manufacturers?

Quality assurance comes from recognized standards that confirm reliability in both production and application.

- ASTM A403 fittings: verify compliance for stainless steel 304, 316, and 316L materials.

- ASME B16.9 fittings: maintain precise dimensions for elbows, tees, reducers, and caps.

- MSS SP-43 / DIN 2605 / EN 10253-2: align with global compatibility requirements across industries like water treatment or oil and gas plants.

How does corrosion resistance shape long-term value in industrial systems?

Durable performance depends on the metal’s natural defense against oxidation.

- Stainless steel 316 and duplex stainless steel offer superior protection in chemical processing and marine settings.

- Proper passivation keeps butt weld fittings clean inside pipelines—critical for sanitary food processing lines or high-pressure water treatment setups.

- Corrosion resistant fittings prolong service intervals, lowering maintenance costs year after year.

Which connection types simplify installation & maintenance schedules?

A contractor’s best friend is a fitting that fits quickly yet holds firm under pressure:

★ Flanged fittings ANSI: easily unbolted during overhauls without pipe cutting; great for large diameters such as 4 inch or 6 inch fittings.

★ Threaded fittings NPT: ideal on smaller runs like plumbing system repairs using 1/2 inch or 1 inch connections.

★ Socket weld & compression fittings: deliver tight seals needed by oil and gas installations under heavy load conditions.

Why test durability before placing a bulk order of stainless steel elbows or tees? – short descriptive branch line style –

Longevity hides within tested strength; each manufacturer should prove it through hydrostatic checks and heat resistance results on high temperature & high pressure fittings made from stainless steel 316L or carbon steel A234 WPB materials — ensuring those pristine curves of elbows and seamless flow through reducers stand solid when the pipeline breathes under real-world demands.