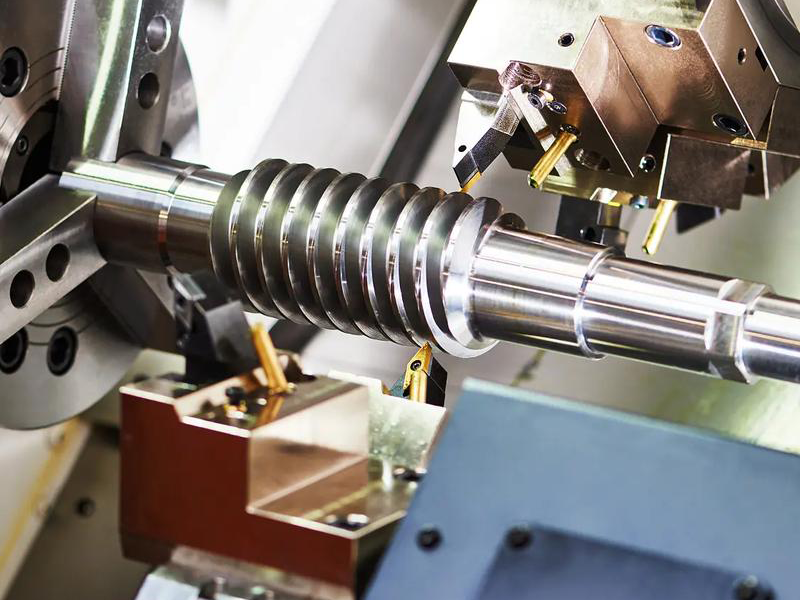

In industrial machinery and automotive systems, grease fittings—also called grease nipples—play a crucial role in maintaining smooth operation and reducing wear. Despite their small size, these components ensure that lubrication reaches bearings, joints, and moving parts efficiently, preventing premature failure and costly downtime.

At Yuhuan Hongqian Machinery Factory, we specialize in precision components and fittings for industrial applications. Understanding the types of grease fittings, their thread standards, and correct installation practices is essential for engineers, maintenance technicians, and equipment manufacturers worldwide. In this guide, we’ll answer key questions like: What thread is on a grease fitting? What is a grease fitting? What is a thread-forming grease fitting? Should you put grease on threads?

What is a Grease Fitting?

A grease fitting is a small mechanical component installed on machinery to allow grease to be injected into bearings or other moving parts. It typically consists of a threaded base, a ball check valve, and a nipple head designed for a grease gun.

The main functions of a grease fitting include:

-

Delivering lubricant precisely to critical areas.

-

Preventing contamination by sealing against dirt, dust, and moisture.

-

Ensuring operational longevity of machinery components.

Common applications include automotive chassis, industrial machinery, agricultural equipment, and hydraulic systems. These fittings are usually made of steel or stainless steel to resist corrosion and withstand high pressure.

What Thread is on a Grease Fitting?

Choosing the correct thread type for a grease fitting is critical to ensure proper installation and avoid leaks. There are multiple thread standards used globally, and compatibility depends on regional and industrial practices. The most common types include:

1. 1/8″ NPT (National Pipe Thread)

-

Predominant in North America (approximately 60% of grease fittings).

-

Tapered threads ensure a tight seal.

-

Suitable for hydraulic, automotive, and industrial machinery.

2. ¼‑28 SAE

-

Common in the US market (roughly 30%).

-

Straight threads with a ball check to prevent grease backflow.

-

Frequently used in automotive and light industrial equipment.

3. Metric Threads

-

Measured in millimeters, widely used in Europe and Asia.

-

Complies with CNS (China National Standard) and ISO standards.

-

Often used in machinery and automotive parts where metric specifications are standard.

4. BSP / BSPT Threads

-

BSPT (British Standard Pipe Taper) commonly used in European equipment.

-

BSPP (British Standard Pipe Parallel) for straight threads requiring O-ring seals.

-

Not compatible with NPT threads due to different taper and angle.

5. Unified Threads

-

Includes UNC (coarse), UNF (fine), UNEF (extra fine) threads.

-

Standardized for machinery applications in the US, UK, and Canada.

-

Often used when interchangeability across international equipment is required.

Tip for users: Always verify thread type before installing a grease fitting, especially when sourcing components internationally. Misaligned threads can cause leaks or damage to the equipment.

What is a Thread-Forming Grease Fitting?

A thread-forming grease fitting is a specialized type of grease fitting designed to cut or form its own threads in the receiving material during installation.

Key characteristics:

-

Self-tapping: Creates threads in softer metals like aluminum or light steel.

-

Installation efficiency: Reduces pre-drilling or threading operations.

-

Cost-effective: Eliminates the need for additional tapping tools or inserts.

Limitations:

-

Best suited for softer materials; not recommended for hard steels.

-

Requires careful torque control to avoid over-tightening or damaging the parent material.

Should You Put Grease on Threads?

A common question during maintenance or installation is whether to lubricate the threads of grease fittings. The answer depends on the type of fitting and the application:

-

Standard threads (NPT, BSPT, Metric): Applying a small amount of grease or anti-seize compound can make installation easier and prevent galling, especially in high-pressure systems.

-

Thread-forming fittings: Usually installed dry, as lubrication may reduce their ability to form threads in the base material.

-

Maintenance tip: Always follow manufacturer guidelines to ensure the fitting functions properly without compromising the seal.

Using proper torque and thread sealant or Teflon tape where appropriate ensures a leak-free and long-lasting installation.

How to Identify Grease Fitting Threads

Correct identification of grease fitting threads is essential for replacements, repairs, or retrofitting machinery. A simple three-step method is recommended:

-

Determine Thread Type: Check whether the fitting is straight (parallel) or tapered.

-

Measure Thread Pitch: Use a thread gauge to determine threads per inch (TPI) or millimeters per thread.

-

Measure Diameter: Verify the external or internal thread diameter to ensure compatibility.

Quick reference table: Common grease fitting threads

| Thread Type | Taper / Angle | Measurement | Common Market |

|---|---|---|---|

| 1/8″ NPT | Tapered | 1/8″ | US |

| ¼‑28 SAE | Straight | ¼‑28 TPI | US |

| Metric | Straight | mm | EU / Asia |

| BSPT | Tapered | mm | EU / Asia |

| UNC / UNF | Straight | TPI | International |

This method helps maintenance technicians quickly identify fittings and ensures replacements match the original specifications.

Applications of Grease Fittings

Grease fittings are versatile and used across a wide range of industries:

-

Industrial Machinery: Conveyors, presses, and hydraulic systems rely on regular lubrication.

-

Automotive and Commercial Vehicles: Suspension systems, universal joints, and steering components.

-

Agricultural Equipment: Tractors, harvesters, and plows often require multiple grease points.

-

Heavy Equipment & Construction Machinery: Excavators, cranes, and loaders.

-

Marine and Aerospace Equipment: Bearings and moving parts where corrosion resistance is critical.

Choosing the right thread type and fitting ensures smooth operation, reduces maintenance costs, and prevents unexpected downtime.

Selecting the Right Grease Fitting

When choosing grease fittings for your project or maintenance work:

-

Verify Thread Type: Match NPT, SAE, Metric, BSP, or Unified threads to your equipment standard.

-

Select Proper Material: Stainless steel for corrosion resistance, carbon steel for general industrial applications.

-

Consider Installation Method: Standard vs thread-forming fittings depending on base material.

-

Maintenance Considerations: Frequency of lubrication, environmental exposure, and accessibility.

-

Work with a Professional Manufacturer: Reliable suppliers like Yuhuan Hongqian Machinery Factory ensure accurate thread cutting, quality materials, and proper testing.

Proper selection ensures efficient lubrication, safety, and equipment longevity.

Conclusion: Ensuring Reliable Machinery with Correct Threads

Grease fittings may seem small, but they are essential for preventing wear and extending the life of industrial machinery. Understanding the different thread types—NPT, SAE, Metric, BSP, and Unified—and knowing when to use thread-forming fittings or apply lubrication can make a significant difference in system performance.

By following correct identification, installation, and maintenance practices, you ensure machinery operates smoothly and efficiently. Partnering with a professional manufacturer like Yuhuan Hongqian Machinery Factory guarantees high-quality fittings that meet global standards and provide reliable performance across industries.