1. What Is a Screw Plug?

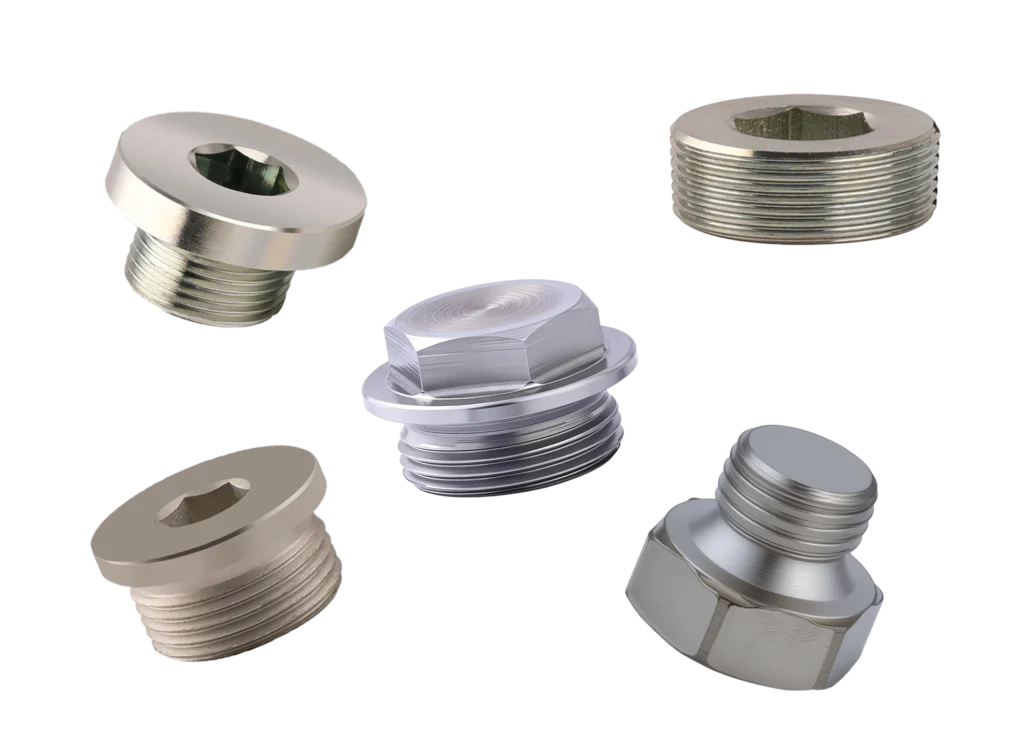

A screw plug is a threaded metal component used to seal, block, or close a hole in a mechanical system. In CNC machining, automotive assemblies, hydraulic manifolds, fuel blocks, pneumatic valve bodies, and plumbing systems, screw plugs are essential for leak-proof sealing.

They are sometimes called threaded plugs, hex socket plugs, Allen plugs, sealing plugs, pipe plugs, hydraulic block plugs, or threaded stop plugs depending on the design and application.

The core purpose of a screw plug is to prevent fluid, gas, lubricant, or pressure leakage while allowing easy removal for maintenance. Standard materials include stainless steel, brass, carbon steel, aluminum, and alloy steel, with surface treatments such as zinc plating, chrome plating, anodizing, black oxide, nickel plating, electroplating, and phosphate coatings for corrosion resistance and durability.

Screw plugs are especially common in:

- Hydraulic valve blocks

- Gearboxes and transmission housings

- Pneumatic cylinders

- Fuel injection bodies

- CNC-machined manifolds

- Industrial pumps and compressors

- Engine lubrication circuits

- Pipe and instrumentation sealing

Their compact design, permanent sealing performance, and reusability give them a strong advantage over welding, rubber caps, expansion blocks, or adhesive sealing methods.

2. What Is the Plug with Screws Called?

In industrial terminology, the plug with screws is commonly known as a threaded plug because it seals a system using inner or outer threads. However, depending on industry standards and geometry, it may also be called:

| Term | Meaning | Industry Use |

|---|---|---|

| Screw Plug | A plug sealed by threads | CNC blocks, hydraulic oil passages, engine housings |

| Threaded Plug | Standard threaded sealing plug | Plumbing, manifolds, compressors |

| Hex Socket Plug | Plug tightened with hex key | CNC manifolds, hydraulic systems |

| Pipe Plug | Seals pipe threads | Instrumentation, water systems |

| Allen Plug | Hex recess type plug | Precision machinery, pumps |

| Hydraulic Plug | Designed for pressure circuits | Excavators, injection molding machines |

| Threaded Stopper | Blocks unused ports | Testing manifolds, valve bodies |

To simplify:

All screw plugs are threaded plugs, but not all threaded plugs are screw plugs in design category.

Different systems use different thread standards:

- NPT / NPTF (tapered)

- BSP / BSPT / G

- DIN / ISO metric

- UNF / UNEF / UNC

- JIS pipe threads

- ORFS, SAE, JIC auxiliary sealing threads

Choosing the correct thread type is essential to prevent pressure loss, thread mismatch, and leakage failure.

3. How to Use a Screw Plug?

Using a screw plug correctly ensures sealing reliability, thread integrity, and long-term system stability.

The basic function of a screw plug is to close and seal unused or maintenance-access ports within a mechanical block.

Usage Guidelines

- Verify matching thread form and tolerance (e.g., NPT vs. BSPT)

- Ensure surface cleanliness before installation

- Apply sealing tape or thread sealant if system pressure is high

- Tighten to manufacturer torque specification

- Check alignment to avoid cross-threading

Where It Is Used

| Application | Purpose |

|---|---|

| Hydraulic valve bodies | Seal hydraulic oil channels |

| Pneumatic blocks | Prevent pressure loss |

| CNC turning and milling components | Close machining access holes |

| Transmission casings | Seal lubrication passages |

| Fuel system manifolds | Stop leakage and maintain pressure |

| Pump modules | Avoid backflow or contamination |

Most CNC machined manifolds include multiple drilled internal oil channels. After machining, unused passages must be sealed with ISO-standard screw plugs to maintain fluid direction and prevent pressure loss.

4. How to Install Screw Plugs? (Step-by-Step Guide)

Correct installation is essential for zero leakage and stable pressure retention.

Step-by-Step Installation

- Clean the Thread Port

- Remove machining oil, burrs, dust, metal chips

- Apply Sealant or PTFE Tape

- For tapered threads and hydraulic circuits only

- Avoid excess wrap to prevent block contamination

- Insert and Align

- Hand tighten first to avoid cross-threading

- Torque Tightening

- Use hex key, torque wrench, or socket wrench

- Follow OEM torque standard (over-tightening causes cracking)

- Pressure Test After Installation

- Conduct hydraulic or pneumatic seal testing

- Inspect for seepage or thread fatigue

Important Installation Tips

- Never apply over-sealant that may enter oil channels

- Avoid repeated removal that may deform threads

- For high corrosion environments, choose stainless steel or nickel-plated steel

- For OEM CNC blocks, always follow machining tolerance drawings

Conclusion

Screw plugs may look small, but they are critical sealing components in hydraulic, pneumatic, and CNC-precision assemblies. From valve bodies to CNC manifold blocks, they ensure no oil, air, or gas escapes from any unused passage. Understanding their thread formats, correct installation sequence, torque control, sealing method, and material choice directly determines whether the system remains leak-free, pressure-stable, and long-lasting.

For OEM and custom CNC screw plugs, consulting exact dimensional drawings, coating standards, and torque specifications ensures high safety performance under continuous industrial operation.