Bulkhead fittings are essential components used to create a secure, leak-proof connection through the wall of a tank, container, reservoir, pipe, or any type of industrial vessel. They allow fluid to enter or exit a container safely while maintaining complete sealing around the penetration point. For anyone working with water systems, chemical tanks, plating lines, filtration systems, aquariums, or industrial processing equipment, bulkhead fittings are one of the most reliable ways to manage fluid flow.

As a CNC turning factory specializing in custom-made metal bulkhead fittings, we manufacture stainless steel, brass, aluminum, and carbon-steel bulkhead connectors with high precision for industrial applications. Our metal bulkhead fittings offer superior pressure resistance, chemical compatibility, long service life, and accuracy compared with molded plastic fittings.

This guide explains what bulkhead fittings are, how they work, and how to install them correctly.

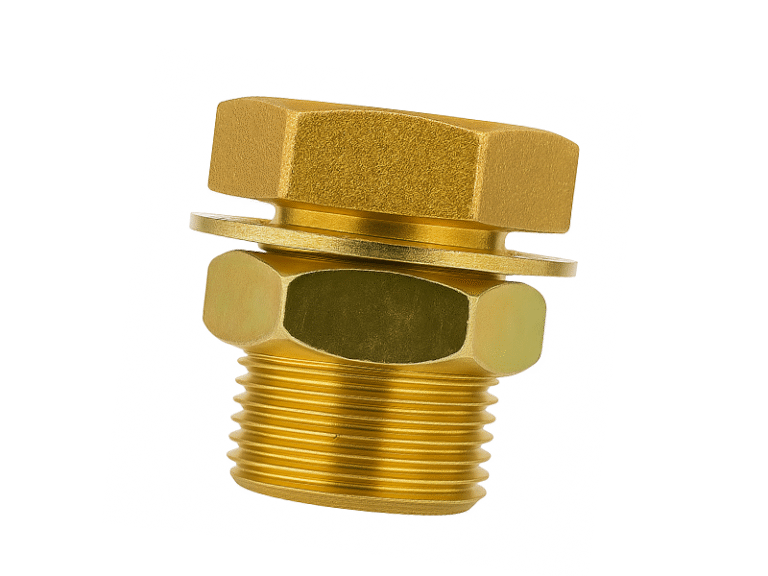

A bulkhead fitting is a threaded connector designed to pass through a wall or barrier—known as a “bulkhead”—and provide a sealed port for fluid transfer. A typical bulkhead fitting consists of:

Body (male/female threaded)

Gasket or O-ring

Locknut

Optional extension or hose adapter

The main purpose of a bulkhead fitting is to create a sealed and stable flow connection through a tank wall. This is especially important when the tank contains:

Water

Oils

Fuel

Chemicals

Plating liquids

Coolant

Wastewater

Hydraulic fluids

Metal bulkhead fittings (stainless steel 304/316, brass, steel) are preferred for:

High temperature applications

High-pressure conditions

Corrosive industrial chemicals

Long-term heavy-duty use

Mechanical load or vibration

Plastic bulkhead fittings (PVC, PP, HDPE) are commonly used in low-pressure and cost-sensitive environments but have limitations in temperature, chemical resistance, and durability.

Bulkhead fittings are used in almost every industry that involves tanks or fluid transfer. Examples include:

Chemical processing tanks

Plating and surface-treatment lines

Water treatment equipment

Aquaculture and aquariums

Agriculture and irrigation tanks

Fuel storage and diesel/waste oil tanks

Hydraulic systems

CNC machine coolant tanks

Industrial filtration systems

As a CNC metal parts manufacturer, we supply bulkhead fittings widely to plating factories, hydraulic equipment builders, tank fabricators, and OEM machine manufacturers.

Installing a bulkhead fitting correctly is crucial for preventing leaks and extending equipment lifespan. Below is a practical, concise installation procedure based on industrial standards.

Before installation, ensure the fitting material and gasket are suitable for the liquid inside the tank.

Examples:

Stainless steel 316 for chemical liquids

Brass for fuel or water

EPDM/NBR/Viton O-rings depending on chemical resistance

Never install a bulkhead fitting while liquid remains above the opening.

This prevents accidents, corrosion, and sealing failure.

Use a marker to mark the exact position on the tank wall. Accuracy ensures correct alignment and proper sealing.

Use a hole saw of the recommended size.

Before drilling the real tank, always test-drill on scrap material to ensure the fitting passes through with minimal side-to-side movement (ideally less than 1/16 inch).

The gasket always goes on the liquid side unless otherwise specified.

Insert the body of the bulkhead fitting through the hole from the inside.

From the outside of the tank, install the locknut and hand-tighten.

Over-tightening can warp the gasket or crack plastic tanks—hand-tight + 1/4 turn is normally enough for plastic tanks.

Metal tanks may accept slightly higher torque, but avoid excessive force.

Tank walls expand and contract with temperature changes.

Avoid connecting rigid pipe directly to the bulkhead.

Instead, use:

Flexible hose

Rubber couplings

Swivel connectors

This prevents stress, cracking, and leaks.

After installation, fill the tank below the fitting and check for leaks.

If no moisture appears after 10–20 minutes, the connection is secure.

Since your blog needs to include your manufacturing capabilities:

As a professional CNC turning factory, we focus on high-precision, high-strength metal bulkhead fittings for demanding industrial environments. Compared with molded plastic fittings, our metal bulkhead fittings offer:

Suitable for hydraulic systems, fuel systems, and industrial tanks.

Especially stainless steel 316 for plating lines, chemical tanks, and corrosive fluids.

Threads, sealing surfaces, and inside bores are CNC-turned to tight tolerances.

We produce metric, BSP, NPT, UNF, or fully customized threads.

Metal bulkhead fittings can be used for years without deformation, cracking, or fatigue.

We support OEM/ODM production, small-batch customization, and mass manufacturing for global customers.

| Part / Trade / Description | Body Thread | Female Pipe Thread | Male Pipe Thread | Length (Overall) | Body Hex (across flats) | Max Grip Length |

|---|---|---|---|---|---|---|

| Bulkhead Fitting, 1-11/16″ | 1″-14 UNS | 3/8″-18 NPTF | 1/2″-14 NPTF | 1-11/16″ | 1-1/4″ | 0.255″ |

| Bulkhead Fitting, 2-1/8″ | 1″-14 UNS | 1/4″-18 NPTF | 1/2″-14 NPTF | 1-29/32″ | 1-1/4″ | 0.465″ |

| Bulkhead Fitting, 1-3/8″ | 7/8″-20 UNEF | 3/8″-18 NPTF | — | 1-3/8″ | 1-1/6″ | 0.305″ |

| Bulkhead Fitting, 2-3/8″ | 1″-14 UNS | 1/2″-14 NPTF | 1/2″-14 NPTF | 2-3/8″ | 1-1/4″ | 0.440″ |

| Bulkhead Fitting, 1-5/16″ | 1″-14 UNS | 3/8″-18 NPTF | 3/8″-18 NPTF | 1-5/16″ | 1-1/8″ | 0.625″ |

Bulkhead fittings play an essential role in creating leak-proof fluid connections through tank walls or container surfaces. Understanding what they are and how to install them correctly helps prevent leaks, reduces maintenance costs, and improves overall system reliability.

Whether used for water, fuel, industrial chemicals, plating solutions, or hydraulic systems, choosing the right material and installing the fitting properly ensures long-term performance.

As a CNC turning factory specializing in metal bulkhead fittings, we provide high-precision stainless steel, brass, and custom-machined bulkhead connectors designed for demanding industrial applications. If you need durable, corrosion-resistant, and accurately machined bulkhead fittings for your project or equipment, we can manufacture them to your requirements.