In the realm of modern manufacturing, precision and efficiency reign supreme. One of the revolutionary technologies that have transformed the landscape of manufacturing is Computer Numerical Control (CNC) machining. Among the myriad of CNC applications, CNC turned parts and CNC turning parts stand out as fundamental components in various industries. In this blog, we delve into the essence of CNC turned parts, exploring their significance, applications, and the intricate processes behind their production.

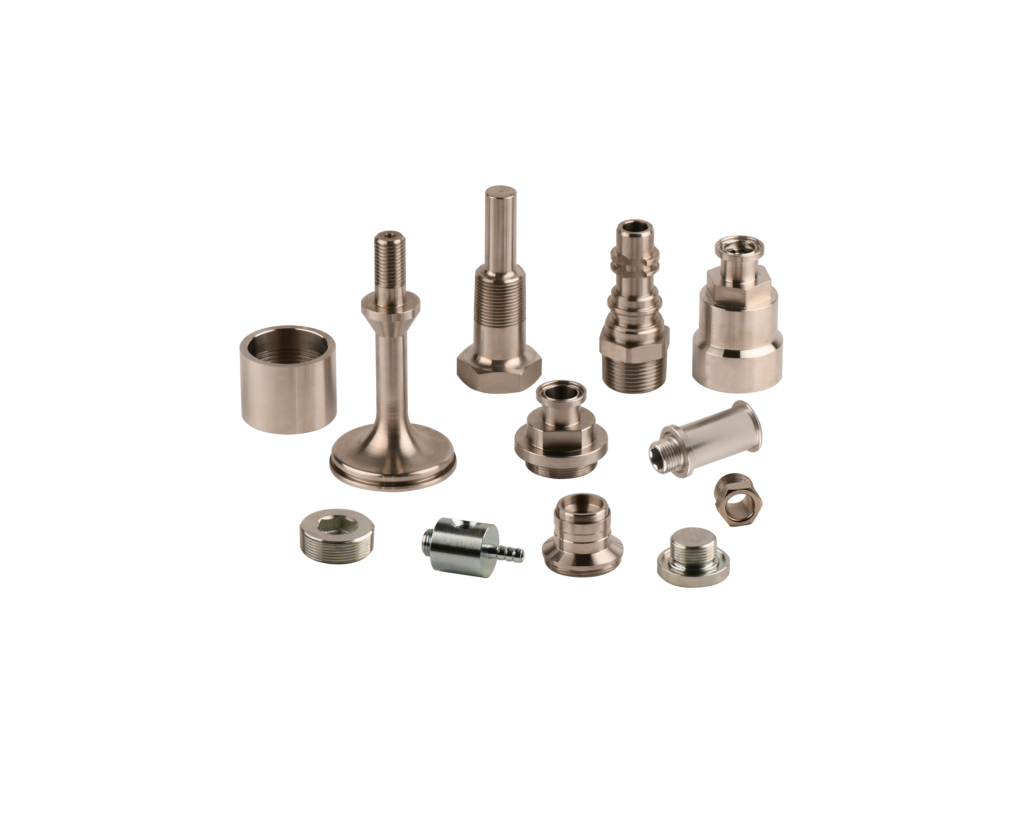

CNC turned parts are essential components produced through the process of CNC turning. This manufacturing technique involves the precision shaping of materials such as metals, plastics, and composites using computer-controlled lathes or turning machines. These machines rotate the workpiece while cutting tools remove material, creating intricate shapes and geometries with high accuracy and consistency. Modern factories—such as Yuhuan Hongqian Machinery Co., Ltd, a leading CNC turning service provider in China—utilize advanced turning centers to ensure stable quality and reliable performance.

Precision:

CNC turned parts boast unparalleled precision, allowing for tight tolerances and intricate designs that meet the exact specifications of the intended application.

Versatility:

From simple cylindrical shapes to complex contours, CNC turning accommodates a wide range of part geometries and sizes, making it suitable for diverse industrial requirements.

Material Compatibility:

CNC turned parts and CNC turning parts can be fabricated from various materials, including aluminum, steel, aluminum, and plastics, offering flexibility in material selection based on application-specific needs.

Efficiency:

CNC turning processes are highly efficient, enabling rapid prototyping, short production lead times, and cost-effective manufacturing solutions. Modern CNC turning services significantly enhance production speed while maintaining consistent quality.

The versatility and precision of CNC turned parts render them indispensable across numerous industries, including:

Automotive:

Used in shafts, bushings, connectors, engine components, and precision steel fittings requiring durability and reliability.

Aerospace:

Critical aircraft components including landing gear parts, hydraulic elements, actuators, and instrumentation rely on CNC turning.

Electronics:

CNC turning parts are used in connectors, terminals, miniature housings, and critical components for electronic devices.

Medical:

Surgical instruments, implants, prosthetics, and precision diagnostic equipment use CNC turned parts for accuracy and safety.

Industrial Machinery:

Hydraulic fittings, pneumatic components, gears, and custom machined elements benefit from CNC turning’s precision and stability.

The production of CNC turned parts involves several sequential steps:

Material Selection:

Materials are chosen based on the mechanical properties and performance required.

Programming:

CAD/CAM software generates high-accuracy digital models and toolpaths for CNC turning machines.

Setup:

The workpiece is mounted securely, and tools are adjusted for optimal machining performance.

Machining:

The CNC machine rotates the workpiece while cutting tools remove material and create the programmed shape with exceptional precision.

Quality Assurance:

Dimensional checks, surface inspections, and performance tests ensure compliance with industry standards.

Finishing Operations:

Deburring, polishing, threading, knurling, and other finishing processes enhance the functionality and appearance of CNC turning parts.

In the realm of modern manufacturing, CNC turned parts stand as exemplars of precision engineering and technological innovation. From aerospace to automotive industries, electronics to medical applications, the versatility and reliability of CNC turning continue to drive advancements and propel industries forward. As technology evolves and manufacturing processes continue to refine, CNC turning parts will remain at the forefront, shaping the future of industrial production with their precision, efficiency, and limitless possibilities.

Yuhuan Hongqian Machinery Co., Ltd, located in the well-known manufacturing hub of Yuhuan, China, is a trusted supplier of high-quality CNC turned parts and CNC turning parts. The company delivers professional CNC turning services using advanced automation, precision machinery, and strict quality control.

From raw material selection to final inspection, every component is produced with exceptional accuracy, smooth finishes, and reliable performance. Whether manufacturing custom precision bushings, fittings, connectors, shafts, or threaded components, Yuhuan Hongqian Machinery ensures consistency, durability, and fast turnaround times.

Their commitment to precision engineering and customer satisfaction positions them as a leading CNC turned parts manufacturer, supplying industries worldwide with dependable components that support the smooth operation of machinery and systems.