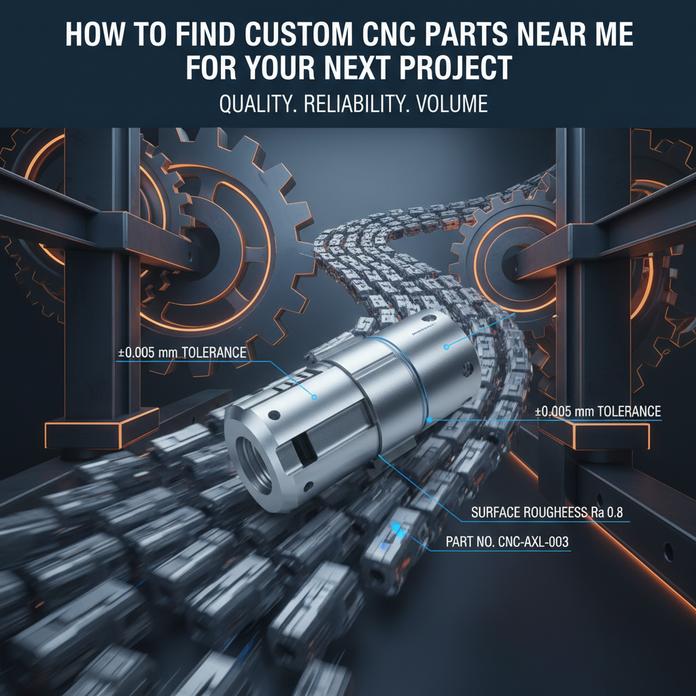

CNC machine parts processing, need to pay attention to the following matters:

First, workpiece fixing and clamping

Stable clamping: Ensure that the workpiece is firmly clamped on the machine tool to prevent vibration or movement during processing, affecting the processing accuracy and workpiece quality.

Fixture selection: Select the appropriate fixture according to the workpiece shape and processing requirements to ensure the accurate positioning of the workpiece.

Clamping strength: clamping strength should be moderate, both to prevent the workpiece from moving, but also to avoid damage to the workpiece.

Second, tool selection and clamping

Tool matching: Select the right tool according to the processing material, processing requirements and machine tool performance, including the type, material and grinding state of the tool.

Clamping accuracy: When clamping the tool, ensure that it is well matched with the tool handle and the tool sleeve, tighten firmly, and avoid the tool falling off or deviating.

Tool inspection: Check the wear of the tool before processing to ensure that the tool is sharp and avoid excessive tool wear affecting the processing quality.

Third, processing parameter setting

Reasonable setting: According to the processing material, tool state, processing form and other factors reasonable selection of cutting speed, feed speed, cutting depth and other processing parameters.

Parameter adjustment: Check the processing parameters regularly, and make necessary adjustments and corrections according to the actual situation to ensure the processing quality and efficiency.

Avoid overload: Avoid setting too high cutting parameters, resulting in overload of the machine tool or tool, affecting the processing accuracy and machine life.

Fourth, machine maintenance and maintenance

Regular cleaning: Regularly clean the machine tool, including the table, fixtures, tools and other parts of the iron filings, oil and other debris, to maintain the cleanliness of the machine tool.

Lubrication maintenance: Regular maintenance of the lubrication system of the machine tool to ensure sufficient and clean lubricating oil, reduce machine wear.

Component inspection: Regularly check the parts of the machine tool, such as guide rail, lead screw, bearing, etc., find wear or damage timely replacement or repair.

Fifth, processing monitoring

Real-time monitoring: real-time monitoring of the operating status and processing quality of the machine tool during the processing process to ensure the normal operation of the machine tool and the quality of the workpiece.

Abnormal handling: If an abnormal situation or fault is found, it should be stopped immediately for inspection and processing to avoid greater losses.

Sixth, safe operation

Compliance with regulations: strictly abide by the safe operation regulations of CNC machine tools to ensure the personal safety of operators.

Wear protection: The operator should wear appropriate protective equipment, such as safety helmet, protective glasses, protective gloves, etc.

Non-professional operation: Non-professional personnel are prohibited to operate CNC machine tools to avoid accidents.

Seventh, other precautions

Clear processing route: shorten the processing route as much as possible, reduce tool empty travel time, improve processing efficiency.

Reasonable choice of fixture: choose a general fixture to clamp the workpiece, avoid using a special fixture, in order to reduce positioning errors and tool change time.

Keep the equipment stable: ensure that the CNC machine tool is placed on a smooth ground to avoid the impact of vibration and shock on the machining accuracy.

In summary, CNC machine parts need to pay attention to many aspects of the processing to ensure processing quality and efficiency. At the same time, the operator should also have rich experience and professional knowledge to deal with the various problems and challenges that may arise during the processing.