At Yuhuan Hongqian Machinery, we specialize in manufacturing a wide range of threaded hose fittings, serving industries that demand precision, reliability, and high-quality connections. With years of experience in producing various types of threads for hose fittings ,tube fittings , pipe joint ,steel plugs , 90 degree elbow etc .

For this blog we main discusss the npt and the nptf thread hose fitting in plumbing system .

| Thread Type | Full Name | Thread Angle | Thread Shape |

|---|---|---|---|

| NPT | National Pipe Tapered | 60° | Tapered |

| BSPT | British Standard Pipe Tapered | 55° | Tapered |

| NPTF | National Pipe Tapered Fuel / Dryseal | 60° | Tapered |

| NPSM | National Pipe Straight Mechanical | 60° | Straight |

| M | Metric Thread | 60° | Straight |

| G | BSP Parallel (Gas Thread) | 55° | Straight |

| UN | Unified National Thread | 60° | Straight |

| UNF | Unified National Fine Thread | 60° | Straight |

The NPT standard (National Pipe Tapered threads) originated in the United States during the late 1800s. This period of rapid industrial growth created an urgent need for standardized piping systems. Before NPT was established, the lack of uniformity in pipe threads often led to frequent leaks and failures in piping systems. Recognizing the critical need for a consistent and reliable standard, engineers and industry leaders developed NPT threads to ensure leak-proof and secure connections.

NPT stands for National Pipe Tapered threads, a standardized threading system used widely in plumbing and piping applications to ensure a secure, leak-proof connection. The defining characteristic of NPT threads is their tapered design. This means the threads gradually decrease in diameter along the length of the pipe at a 1:16 taper ratio.

This taper is essential as it causes the threads to compress against one another when screwed together, forming a mechanical seal. To further enhance the seal and prevent leaks, a thread sealant, such as PTFE tape or pipe dope, is typically applied.

NPT (National Pipe Tapered) threads possess several distinct features that make them the standard choice for secure piping connections throughout North America (including the United States and Canada).

Tapered Design (Self-Sealing): Unlike straight threads, NPT threads feature a specific taper of 1:16 taper ratio. This crucial design allows the threads to physically tighten and compress against each other as they are assembled, effectively creating the required seal.

Thread Form: The threads are cut at a 1:16 taper ratio. ensuring strong and reliable engagement (meshing) when coupled.

Size Range and Specification: NPT threads are available in a wide range of nominal pipe sizes (NPS), typically starting from $1/16$ inch up to $24$ inches.

Compliance Standard: The precise dimensions and tolerances of NPT threads are strictly governed by the ANSI/ASME B1.20.1 standard, ensuring universal compatibility and quality across all components used in US-based plumbing and industrial systems.

Npt thread is one important hose fitting thread used in plumbing systems .

NPT threads are fundamental to creating a reliable, leak-proof seal in plumbing systems. The entire principle revolves around their unique tapered structure. As a male NPT fitting is screwed into a female counterpart, the taper forces the threads to compress tightly against each other, establishing a strong mechanical seal. This compression is further reinforced by applying thread sealants like PTFE tape or pipe dope, which fill any microscopic gaps. This combination ensures the connection can safely contain fluid or gas, making it indispensable for maintaining the overall integrity of pipelines.

A key advantage of NPT threads lies in their inherent simplicity compared to straight (parallel) threads. While straight threads provide a solid mechanical connection, they do not inherently seal and therefore require an additional sealing mechanism, such as O-rings or gaskets, to prevent leaks. The tapered design of NPT, however, is self-sealing due to the built-in thread compression. This feature eliminates the necessity for separate sealing elements, which translates into easier installation, fewer potential failure points, and enhanced reliability across vast plumbing networks.

Due to their dependable seal, NPT threads are the dominant standard in plumbing and piping across North America . They are essential in a wide range of applications, from basic residential water supply and gas lines to complex systems in commercial and industrial settings. NPT’s ability to withstand high pressure makes it ideal for demanding environments like steam systems and large-scale fluid distribution networks. Key NPT-threaded components include all standard pipes, essential fittings like elbows and tees, couplings, and crucial flow control valves.

While standard NPT threads require sealants to ensure a leak-proof connection, NPTF (National Pipe Taper Fuel) threads—often referred to as “Dryseal” threads—are engineered to form a reliable seal without them. NPTF achieves this by utilizing significantly tighter tolerances at the crest and root of the threads. Upon tightening, the mating threads mechanically deform and crush the base material, creating a direct metal-to-metal seal that is secure against leakage. This critical feature makes NPTF the preferred choice for sensitive applications, such as fuel, gas, and critical hydraulic systems, where introducing thread sealants could contaminate the fluid or where the highest degree of sealing reliability is non-negotiable

The ability of NPTF (National Pipe Taper Fuel) threads to create a reliable Dryseal without external sealants is a direct result of its superior precision requirements. While both NPTF and standard NPT share the 60 degree thread angle and 1:16 taper ratio, NPTF threads are manufactured to stricter specifications with tighter tolerances on the crest and root. This design ensures that when the male and female fittings are assembled, the threads mechanically interfere and crush the base metal into itself.

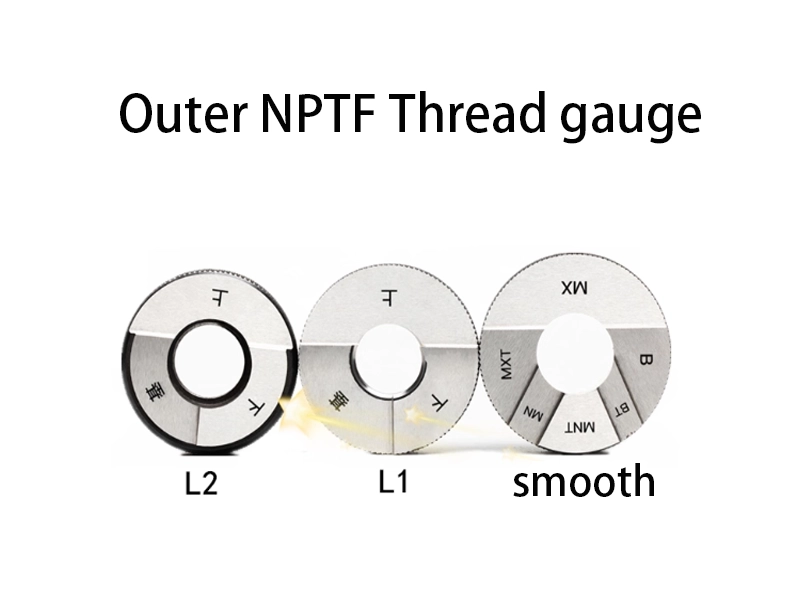

Crucially, this metal-to-metal seal necessitates rigorous quality control: Unlike standard NPT threads which can be checked with a single gauge, NPTF fittings must pass inspection using three separate gauges. This three-gauge system guarantees the extreme accuracy needed to achieve the required crest, root, and flank interference. This high precision ultimately eliminates the spiral leakage path, making NPTF the essential choice for applications like fuel and high-pressure hydraulic systems where contamination risk and high reliability are paramount.

Proper preparation is the foundational step for any secure and leak-proof NPT connection in plumbing and hydraulic systems across North America. First, carefully inspect the threads on both the male and female fittings for any signs of damage, nicks, or debris that could compromise the seal. Next, thoroughly clean the threads using a wire brush or cleaning tool to remove old sealant or dirt. It is crucial to ensure the threads are completely dry before proceeding, as moisture can interfere with the effectiveness of the sealing compound.

For standard NPT threads, the application of a high-quality sealant is essential to enhance the mechanical seal provided by the taper. The most common practice involves wrapping the male threads clockwise (as viewed from the pipe end) with PTFE tape (2-3 wraps are typically sufficient). Alternatively, a thin, even layer of pipe dope (thread sealant paste) can be applied. In high-vibration or critical industrial environments, anaerobic thread sealants may be used, which cure in the absence of air to create a strong, durable bond suitable for demanding applications.

Achieving a reliable connection requires careful control during tightening to avoid thread damage. Begin by hand-tightening the components until they are snug; this confirms the threads are correctly engaged and prevents cross-threading. Then, use a wrench for final tightening—generally, an additional 1 to 2 full turns are adequate to achieve the necessary compression. It is vital to avoid over-tightening, as excessive force can strip the threads or distort the fittings, thus compromising the integrity of the tapered seal and increasing the risk of failure in the system.

NPT and NPTF share the same thread angle, pitch, and taper (1:16), which is why they can be physically engaged during assembly. In real production scenarios, customers often accept using NPTF as a substitute for NPT, and this leads many to assume the two are fully interchangeable.

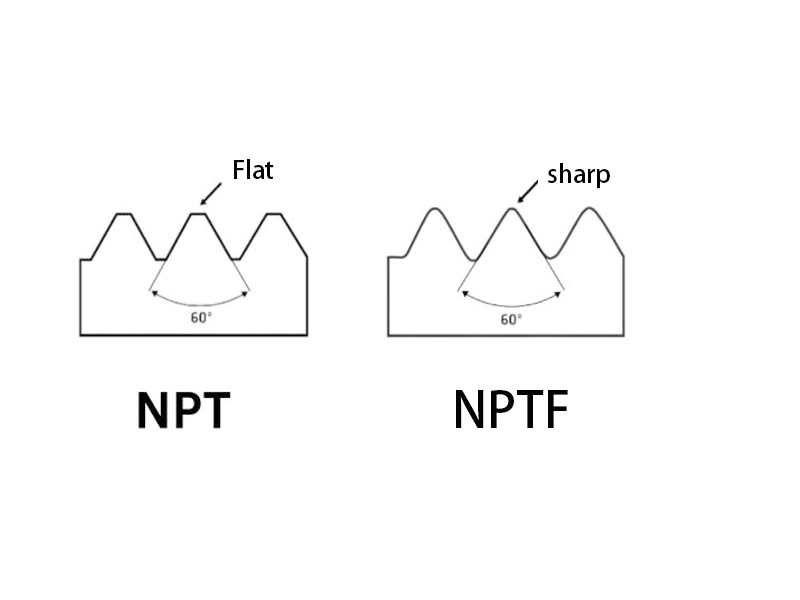

However, this is only partially true. While the threads can mate, the sealing performance is not identical. More detail you can check the photo NPT VC NPTF , the nptf thread top is sharp , Npt thread top is flat . NPT relies on thread interference plus sealants such as PTFE tape or thread compound, whereas NPTF features a precision dry-seal design intended to achieve metal-to-metal sealing without additional sealing materials.

In other words:

NPT and NPTF can fit together, but they do not guarantee the same sealing reliability.

They are mechanically compatible to a degree, but not functionally interchangeable in strict engineering terms—especially in high-pressure, fuel, or hydraulic systems where leak-free performance is critical.

Both thread forms look the same and follow the same taper specification.

Many users have historically accepted substitution during production.

With sealant applied, NPT can perform adequately in lower-pressure fluid and air systems, which reinforces the belief that they are equivalent.

NPT ↔ NPTF can mate, but sealing reliability depends on system pressure, media, and sealing method.

NPTF offers superior dry-seal capability and should be used when leakage is not acceptable.

Treat NPTF not as a simple replacement, but as a precision sealing upgrade rather than a direct NPT substitute.

This article has provided a comprehensive overview of NPT and NPTF thread standards, detailing their distinct mechanisms for achieving secure, leak-proof seals, and exploring the fundamental principles behind their application. We covered essential knowledge regarding thread forms, the precise testing required for NPTF’s Dryseal connection, and shared best practices for installing and maintaining NPT fittings in various systems. We sincerely invite our readers to share your knowledge and experiences regarding the practical application and maintenance of these crucial tapered pipe threads in your own industrial or plumbing projects.