You’re not just picking a cnc turned parts manufacturer—you’re betting on your production line’s pulse. One bad fit, and suddenly your delivery schedule’s doing the cha-cha while your tolerance specs vanish into thin air.

Think about it: you wouldn’t hire a wedding DJ who only owns a kazoo. So why gamble on precision machining without asking what kind of machines are spinning behind the curtain? Multi-axis or bust, baby.

According to Deloitte’s 2023 Global Manufacturing Outlook, 72% of procurement leads said supplier consistency mattered more than cost when volumes scaled fast. Translation? You need partners who don’t flinch under pressure.

This guide’s for folks juggling POs like hot potatoes and praying their suppliers picked up the phone yesterday—because in this game, reliability isn’t optional, it’s oxygen.

Essential Insights for Choosing a CNC Turned Parts Manufacturer

- Manufacturer Capabilities: Evaluate the equipment and expertise to ensure they meet your production standards.

- Quality Certifications: Look for ISO and other relevant certifications to guarantee adherence to quality and safety standards.

- Turnaround Time: Assess the efficiency and flexibility of production schedules to meet your demands.

- Tolerances and Surface Finish: Prioritize manufacturers with proven capabilities in achieving tight tolerances and excellent surface finishes.

- Material Selection: Understand how the choice of materials affects product performance and durability, and leverage prototyping for optimal decision-making.

Understanding the Role of a CNC Turned Parts Manufacturer

A sharp look into how a CNC turned parts manufacturer reshapes precision industries with tech, tools, and tight quality control.

How CNC Turning Revolutionizes Modern Manufacturing

- Mass production used to mean mass compromise. Not anymore.

- With automation, even small batches now hit big-league precision.

- A single operator can run multiple machines thanks to digital interfaces.

- Tight tolerances? Check. High repeatability? Double check.

- Quick tool changes keep downtime almost nonexistent.

- CAD/CAM integration allows seamless design-to-production flow.

• Aerospace and medical sectors rely on this speed-meets-accuracy combo.

From prototyping to full-scale production, modern-day CNC turning is the engine behind innovation across industries like automotive and electronics. It’s not just about spinning metal anymore—it’s about injecting efficiency into every layer of your supply chain using technology, smart programming, and ultra-fast cycle times.

Short-run jobs? Done fast without sacrificing accuracy. Long-run orders? Scalable without blinking an eye.

Key Equipment in CNC Turning: Lathes and Multi-Axis Machines

Grouped by function, here’s what powers a top-notch CNC turned parts manufacturer:

🛠️ Core Machines:

- CNC lathes – Rotate raw material against cutting tools for cylindrical parts

- Swiss-type lathes – Ideal for small-diameter components needing ultra-fine detail

🔄 Motion & Complexity Enhancers:

- Live tooling systems – Enable milling while turning, reducing setup time

- Multi-axis machines – Add X, Y, Z plus rotational axes for complex geometries

📐 Interface & Design Tools:

- Integrated CAD/CAM platforms – Bridge design with machine execution seamlessly

- Precision linear guides – Boost stability during high-speed operations

| Machine Type | Axis Count | Max RPM | Common Use Case |

|---|---|---|---|

| Standard CNC Lathe | 2 | 4,000 | General part shaping |

| Swiss-Type Lathe | Up to 8 | 12,000 | Micro-machined components |

| Mill-Turn Center | 5+ | 10,000 | Complex aerospace parts |

| Multi-Spindle Lathe | Varies | Varies | High-volume production |

Every piece of equipment is tailored to meet specific demands—from delicate medical implants to rugged auto components—making each shop floor its own kind of mechanical orchestra.

Quality Control Measures in CNC Turned Parts Production

Precision isn’t optional—it’s gospel when it comes to producing reliable turned parts.

Each component that rolls off the lathe undergoes stringent checks using advanced metrology gear like CMMs, laser scanners, or digital micrometers. These tools don’t just measure—they verify against tight tolerances that sometimes go down to microns.

The process typically begins with first article inspection before moving on to mid-batch sampling and final dimensional audits—a loop that ensures no bad apple sneaks past the gate.

As noted by the International Journal of Advanced Manufacturing Technology (2024), “consistency in dimensional accuracy directly correlates with brand reputation across global supply chains.”

Beyond hardware checks, ISO-certified shops implement layered documentation protocols under strict quality assurance frameworks—every part gets tracked from raw stock to finished product under globally recognized standards like AS9100 or ISO/TS16949.

That’s how a seasoned cnc turned parts manufacturer earns trust—not just through output but through certified reliability baked right into their process DNA.

5 Tips for Choosing a Reliable CNC Parts Manufacturer

Picking the right CNC turned parts manufacturer isn’t rocket science—but it sure helps to know what to look for. Here’s how to separate the pros from the pretenders.

Assessing Manufacturer Capabilities: Equipment and Expertise

- You want a shop that’s not stuck in the Stone Age. Look for modern CNC machines, multi-axis machining centers, and updated CAD/CAM software.

- Ask if they’ve got experienced hands—like seasoned machinists and real-deal engineering expertise, not just someone pushing buttons.

- If you’re dealing with large orders, don’t forget to ask about their actual production capacity.

A solid CNC turned parts manufacturer doesn’t just own shiny tools—they know how to use them to meet your specs without sweating.

Importance of Quality Certifications in CNC Manufacturing

- ISO 9001? Check. AS9100? Even better.

- These aren’t just fancy acronyms—they mean the company has real-deal quality management systems in place.

- Regular internal audits, documented processes, and full-on traceability are signs you’re not dealing with guesswork.

A certified shop takes precision seriously, using tight inspection routines and regulatory standards as their north star—so you don’t get burned by sloppy parts later on.

Understanding Turnaround Time and Production Flexibility

• Ever dealt with a vendor who ghosts you when deadlines loom? Don’t go there again.

• Ask about average lead time, but also what happens when you throw them a curveball—a rush job or last-minute tweak.

• A responsive team that can handle both prototyping and scaling up is gold.

The best shops balance high-speed delivery with adaptability, making sure your supply chain doesn’t hit a wall when demand shifts.

Critical Features to Look for: Tight Tolerances and Surface Finish

- Not all metal parts are created equal—especially when it comes to tolerances. Look for consistent delivery of sub-millimeter accuracy; think ±0.01mm or tighter.

- A top-tier CNC turned parts manufacturer should offer clean finishes straight off the machine or via post-processing like polishing or anodizing.

- Don’t forget about inspection—rigorous checks using CMMs or laser scanners ensure every part matches your drawings down to the decimal.

You want someone who treats each spec like gospel—from ultra-smooth surfaces to precise hole diameters—and backs it all up with legit measurements every time.

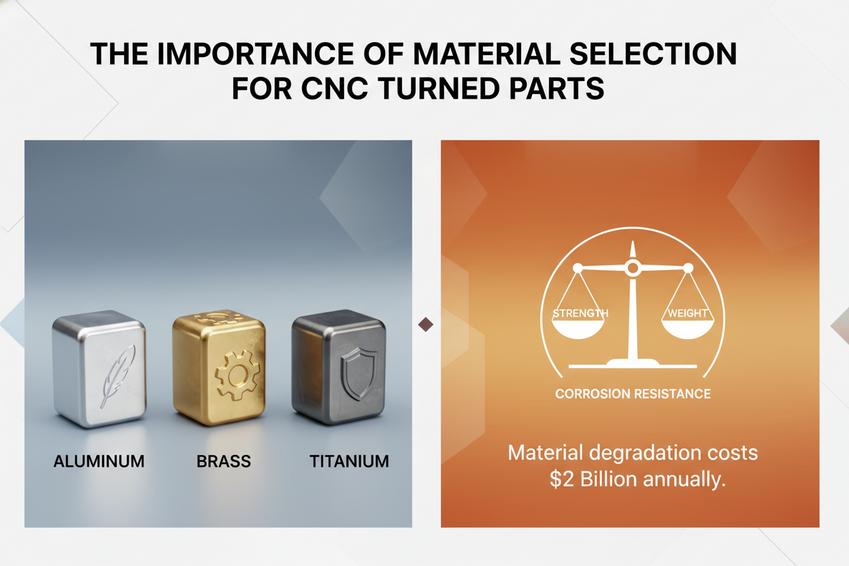

The Importance of Material Selection for CNC Turned Parts

Choosing the right material isn’t just technical—it’s a game changer in how your parts perform, last, and cost you.

Common Materials Used: Aluminum Alloys, Brass, and Titanium

- Aluminum Alloys: Lightweight and easy to machine—ideal when speed and weight are key.

- Brass: Great for precision work thanks to its outstanding machinability, often used in plumbing or electronics.

- Titanium: Super tough, corrosion-resistant, and perfect for high-stress applications like medical implants or aerospace components.

- Bonus tip? Each material has trade-offs in cost, durability, and finish quality—so don’t just go with what looks good on paper.

Impact of Material Choice on Product Performance

• A part made from the wrong material can fail way too soon—or cost way more than it should.

• Using a high-strength alloy boosts durability but might increase machining time.

• Want lighter parts? Go with something like aluminum—but be ready to sacrifice some strength.

The balance between strength, weight, and corrosion resistance often defines whether a product thrives or flops.

How Prototyping Affects Material Selection Decisions

Short runs using different materials let engineers test real-world performance before going all-in on production. That’s where prototyping shines—it helps uncover how each option handles stress, wear, or heat without blowing the full budget.

When you’re working with a seasoned cnc turned parts manufacturer, they’ll usually recommend prototyping early on. It’s not guesswork; it’s smart planning that reduces risk big time.

Aluminum Alloys for Lightweight Applications

Grouped by application needs:

- Aerospace & Drones:

- Prioritize low weight + high strength.

- Automotive Components:

- Use when fuel efficiency matters.

- Consumer Electronics:

- Ideal for heat dissipation + sleek finishes.

Aluminum alloys bring solid material properties, especially when every gram matters. For any cnc turned parts manufacturer focused on speed-to-market, aluminum is often step one.

Brass as an Ideal Choice for Precision Machining

Grouped by advantages:

- High Workability:

- Cuts cleanly = less tool wear.

- Dimensional Accuracy:

- Holds tight tolerances without warping.

- Corrosion Resistance:

- No need for extra coatings in many cases.

Because of its excellent machinability, brass is often chosen by manufacturers needing fast turnaround times without sacrificing precision—especially in fittings or electrical terminals.

Titanium’s Strengths in High-Stress Environments

Multiple short segments:

Titanium doesn’t play around—it thrives under pressure where other metals give up. Its insane strength-to-weight ratio makes it perfect for surgical tools or jet engine components. And if corrosion gives you headaches? This metal laughs at rust—even underwater or inside the human body.

That’s why top-tier cnc turned parts manufacturers keep titanium in their back pocket for mission-critical jobs that can’t afford failure.

Cost Considerations When Choosing Materials

Grouped by factors:

- Raw Material Price:

- Titanium > Brass > Aluminum> Stainless steel > Carbon steel

- Machining Time & Tool Wear:

- Brass is cheapest to machine, thn aluminum

- Titanium costs more due to slower cutting speeds

- Waste & Recyclability:

- Aluminum wins here hands down

A smart cnc turned parts manufacturer will weigh all three before recommending anything—because saving pennies upfront can cost dollars later if the part fails early or takes forever to make.

Role of Corrosion Resistance in Harsh Environments

Natural combination format:

In marine settings? You’ll want something like titanium that shrugs off saltwater exposure. In humid industrial zones? Brass might corrode slower than steel but still needs protection over time.

Corrosion resistance isn’t just about avoiding rust—it impacts long-term maintenance costs too. According to a recent report from GlobalSpec Insights published Q1 of 2024, “Material degradation accounts for nearly $2 billion annually in replacement costs across manufacturing sectors.”

So yeah—ignore this factor at your own risk.

Heat Resistance Requirements Across Industries

Grouped by industry demand:

- Aerospace & Defense:

- Requires materials stable above 500°C

- Titanium leads here

- Automotive Braking Systems:

- Needs metals that won’t warp under frictional heat

- Some aluminum alloys qualify

- Power Electronics Housings:

- Must dissipate heat efficiently while staying cool outside

- Brass performs well here due to thermal conductivity

Each industry leans into different priorities—but every cnc turned parts manufacturer knows thermal behavior changes everything when tolerances are tight and failures aren’t an option.

Balancing Machinability and Functionality During Design Phase

Natural mix of formats:

It’s tempting to pick the toughest material possible—but if it kills your tooling budget or adds three weeks per batch? Not worth it unless absolutely necessary. That’s why machinability walks hand-in-hand with functionality during design reviews.

A skilled cnc turned parts manufacturer will guide you through these trade-offs early so you’re not stuck reworking designs halfway through production—a costly mistake nobody wants twice.

And hey—sometimes a slightly softer alloy gets the job done better because it’s easier to shape precisely within spec limits while still meeting all functional requirements like load-bearing capacity or thermal tolerance.

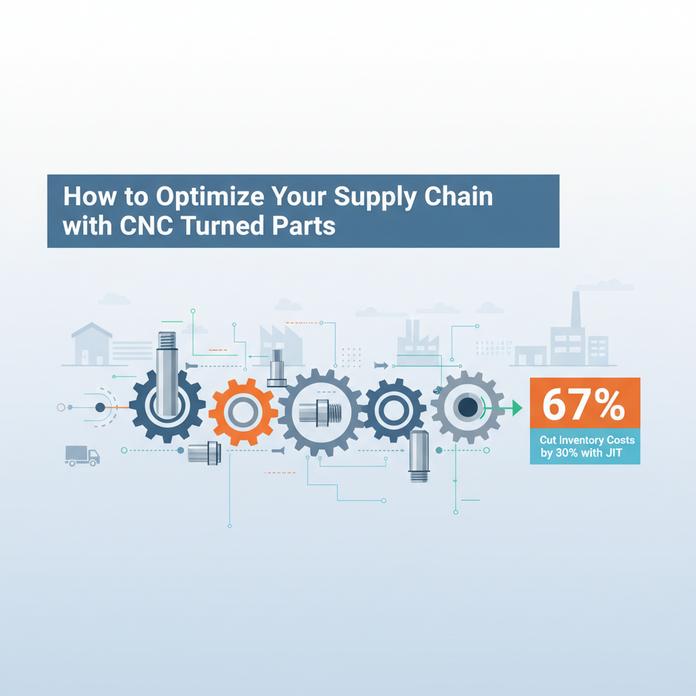

How to Optimize Your Supply Chain with CNC Turned Parts

Smart supply chains aren’t just about speed—they’re about precision, adaptability, and shaving off waste at every turn.

Streamlining Logistics: From Design Assistance to Delivery

Design tweaks and delivery delays can wreck your margins if you’re not careful. Here’s how smart logistics with a reliable cnc turned parts manufacturer can flip the script:

• Design support that starts early reduces rework later—engineers can collaborate on specs before tooling even begins.

• Real-time tracking ensures on-time delivery, so you’re not left guessing when parts will show up.

• Tight coordination between supplier and buyer boosts supply chain efficiency, especially during demand spikes or custom orders.

Now toss in smarter inventory management, where low-volume runs mean less warehouse clutter. When paired with proactive supplier collaboration, you’re not just outsourcing parts—you’re building a relationship that keeps your whole manufacturing process nimble.

Yuhuan Hongqian makes this entire cycle smoother by offering integrated services right from CAD input to final shipment, making them more than just another name on a PO list.

Leveraging CNC Turning for Just-in-Time Manufacturing Strategies

Big factories aren’t the only ones who can run lean anymore—thanks to modern CNC turning, even mid-size shops are getting slick with their Just-in-Time setups:

- Small-batch flexibility means you only produce what’s needed—no more stockpiling “just in case.” That’s pure gold for tight budgets.

- Fast turnaround times allow you to sync production directly with customer demand.

- Better precision = fewer defects = less scrap = lower costs across the board.

According to Deloitte’s 2024 Smart Manufacturing Report, over 67% of manufacturers using JIT workflows say they’ve cut inventory holding costs by at least 30%. That’s no small feat—and it highlights how vital accurate machining is when using a trusted cnc turned parts manufacturer.

With rapid prototyping capabilities baked into the process, teams can test and tweak designs fast without blowing deadlines or budgets. This combo of speed and accuracy makes it easier than ever to align production cycles with real-world sales data, keeping shelves stocked just right—not too much, not too little.

And when you choose a shop like Yuhuan Hongqian that specializes in high-efficiency turning processes, you’re setting yourself up for smoother operations from quote request all the way through fulfillment.

FAQs about CNC Turned Parts Manufacturer

How can a cnc turned parts manufacturer keep up with large production needs?

Picture rows of CNC lathes and multi-axis machines moving in perfect rhythm—aluminum alloy rods becoming precision shafts, stainless steel transformed into bushings, titanium shaped for aerospace fittings.

- High-speed Swiss screw machines for intricate fasteners in electronics

- Grinding machines and anodizing finishes delivering flawless surface finish

- Round-the-clock production runs balancing volume and accuracy under strict deadlines

Why is material selection such a decisive moment in ordering parts?

Choosing between lightweight aluminum alloy, corrosion-resistant stainless steel, resilient carbon steel, warm-toned brass or industrious titanium feels like selecting the soul of your product. Each reacts differently to CNC milling, turning or drilling:

| Material | Key Strength | Typical Use | Industry |

|---|---|---|---|

| Aluminum Alloy | Lightweight strength | Housings | Automotive |

| Stainless Steel | Corrosion resistance | Shafts | Medical devices |

| Brass | Electrical conductivity | Connectors | Electronics |

What role does prototyping play before mass orders?

A prototype tells the truth no drawing can hide—it reveals how reaming affects tight tolerances on a housing or how tapping cleanly forms threads in carbon steel fittings. It allows:

- Surface finish inspection before committing resources

- Functional testing across assembly requirements

- Cost adjustments if machining behavior proves complex

Which features show that quality here isn’t just claimed but lived daily?

A genuine cnc turned parts manufacturer shows its character through:

- Precision you can feel—micron-level dimension control for aerospace components

- Heat treatment enhancing durability of automotive shafts

- Quality control teams tracing each bushing’s journey from raw bar to packaged part—every step signed off with pride