Introduction

Metric threads are one of the most commonly used screw threads in modern mechanical manufacturing, yet they are also among the most misunderstood. Markings such as M10, M12, or M10×1.5 appear frequently on drawings, fasteners, and CNC-machined parts, but many buyers and even engineers are not fully clear about what these designations actually mean.

At Yuhuan Hongqian, a manufacturing factory specializing in CNC turning parts and precision machined components, we regularly see assembly issues caused by incorrect thread interpretation—especially confusion between diameter, pitch, and thread standards. This article explains what a metric thread is, what M10 and M12 really mean, and how to correctly read markings like M10×1.5, using practical machining experience rather than textbook definitions. A metric thread chart is also included for reference.

What Is a Metric Thread?

A metric thread is a screw thread defined using millimeters (mm) as the unit of measurement. It is standardized under the ISO metric thread system, which is widely used in Europe, Asia, and most global manufacturing industries.

Key characteristics of metric threads include:

-

Dimensions expressed in millimeters

-

A standard 60° thread angle

-

Designation starting with the letter “M”

-

Diameter and pitch clearly defined

Metric threads are commonly used in CNC turning, milling, automotive components, machinery, industrial equipment, and general mechanical assemblies. As a factory producing threaded CNC parts every day, Yuhuan Hongqian works with metric threads far more frequently than any other thread type.

Does M10 Mean a 10mm Thread?

Yes. M10 means the nominal thread diameter is 10 millimeters.

In metric thread designation:

-

“M” indicates a metric thread

-

“10” refers to the nominal major diameter of the thread in millimeters

However, it is important to understand that nominal diameter does not always equal the exact measured size. Due to thread geometry and tolerance, an external M10 thread may measure slightly less than 10.00 mm at the crest.

In CNC machining, this distinction is critical. At Yuhuan Hongqian, we control thread dimensions based on ISO tolerances rather than simple caliper measurements, ensuring functional fit rather than just theoretical size.

Does M12 Mean 12mm?

Yes. M12 indicates a metric thread with a nominal diameter of 12 millimeters.

The logic is exactly the same as M10:

-

M12 → 12 mm nominal diameter , the real outdiameter around 11.7-11.9mm .

-

The actual measured value depends on tolerance class and thread form

M12 threads are commonly used in structural fasteners, automotive components, and medium-load mechanical parts. In CNC turning operations, M12 threads often require more careful pitch verification because incorrect pitch selection can still allow partial engagement before jamming.

This is a common issue we encounter in production at Yuhuan Hongqian, especially when customers provide incomplete drawings.

What Does M10×1.5 Mean?

This is the most important and most misunderstood metric thread designation.

M10×1.5 means:

-

M → Metric thread

-

10 → Nominal diameter = 10 mm ,uasally thread outdiameter around 9.7-9.9mm.

-

1.5 → Thread pitch = 1.5 mm

Thread pitch is the distance the thread advances in one full rotation. In other words, every 360° turn of an M10×1.5 thread moves the fastener forward by 1.5 mm.

This pitch value is far more critical than many people realize.

Metric Thread Pitch Explained (Why Pitch Matters More Than Diameter)

In real manufacturing and assembly, pitch mismatch causes more failures than diameter errors.

At Yuhuan Hongqian, we often see cases where:

-

The diameter appears correct

-

The thread starts smoothly

-

The fastener jams after 1–2 turns

This usually indicates an incorrect pitch.

For example:

-

M10×1.5 (coarse pitch)

-

M10×1.25 (fine pitch)

These two threads have the same diameter but are not interchangeable. Forcing mismatched pitches will damage threads, cause galling in stainless steel, and lead to premature failure.

In CNC turning, pitch accuracy depends on:

-

Tool geometry

-

Machine synchronization

-

Material hardness

-

Surface finish

This is why functional inspection using thread gauges is more reliable than visual checks alone.

Metric Thread Chart (Sizes and Pitch Table)

Below is a typical metric thread chart showing common sizes and standard pitches. This table is frequently referenced during machining and inspection at Yuhuan Hongqian.

Common Metric Thread table

Coarse Thread 60° Fine Thread 60°

| Thread Size | Pitch (t) | Tap Drill / Minor Diameter | Tap Drill / Minor Diameter | Thread Size | Pitch (t) | Tap Drill / Minor Diameter | Tap Drill / Minor Diameter |

|---|---|---|---|---|---|---|---|

| M3 | 0.50 | 2.50 | 7.50 | M8 | 1.00 | 7.00 | 15.00 |

| M4 | 0.70 | 3.30 | 10.50 | M10 | 1.00 | 9.00 | 15.00 |

| M5 | 0.80 | 4.20 | 12.00 | M12 | 1.50 | 10.50 | 22.50 |

| M6 | 1.00 | 5.00 | 15.00 | M14 | 1.50 | 12.50 | 22.50 |

| M8 | 1.25 | 6.75 | 18.75 | M16 | 1.50 | 14.50 | 22.50 |

| M10 | 1.50 | 8.50 | 22.50 | M18 | 1.50 | 16.50 | 22.50 |

| M12 | 1.750 | 10.25 | 26.25 | M20 | 1.50 | 18.50 | 22.50 |

| M14 | 2.00 | 12.00 | 30.00 | M22 | 1.50 | 20.50 | 22.50 |

| M16 | 2.00 | 14.00 | 30.00 | M24 | 2.00 | 22.00 | 30.00 |

| M18 | 2.50 | 15.50 | 37.50 | M27 | 2.00 | 25.00 | 30.00 |

| M20 | 2.50 | 17.50 | 37.50 | M30 | 2.00 | 28.00 | 30.00 |

| M22 | 2.50 | 19.50 | 37.50 | M33 | 2.00 | 31.00 | 30.00 |

| M24 | 3.00 | 21.00 | 45.00 | M36 | 2.00 | 34.00 | 30.00 |

| M27 | 3.00 | 24.00 | 45.00 | M42 | 2.00 | 40.00 | 30.00 |

| M30 | 3.50 | 26.50 | 52.50 | M48 | 2.00 | 46.00 | 30.00 |

Important note:

Always verify pitch before machining or assembly. Many metric thread failures occur simply because the pitch was assumed rather than confirmed.

How to know coarse thread or fine thread ?

When identifying whether a metric thread is a coarse thread or a fine thread, a simple rule of thumb can be applied: for threads like M10 or M12, if no pitch is specified, they are generally considered coarse threads. Coarse threads have standard, fixed pitches that can be verified in thread charts, making confirmation easy. On the other hand, if the thread is marked with a specific pitch, such as M10×1 or M10×1.25, it is typically classified as a fine thread. This method is straightforward and reliable, providing a quick way to distinguish coarse and fine threads in practical machining and fastening applications.

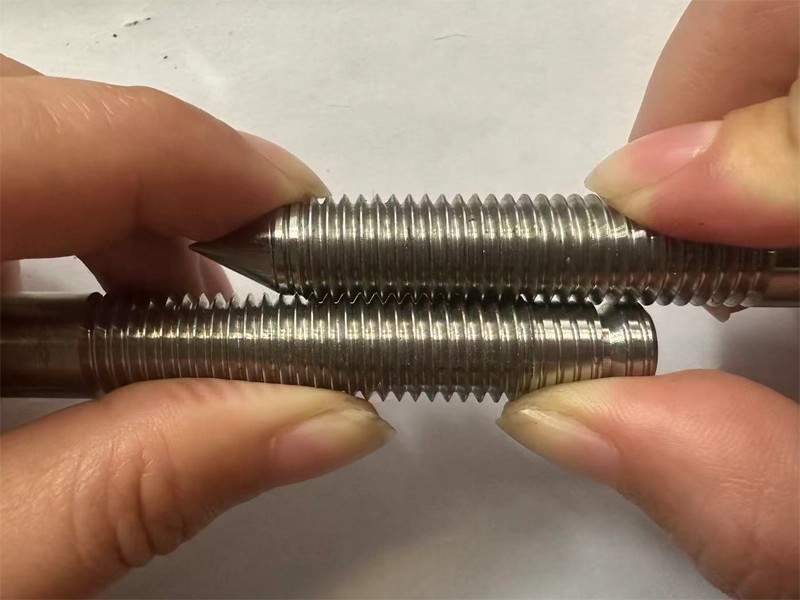

M12 VS M12 thread , when the thread same , this two same thread can combine together .So that is the reason why we can use Thread Pitch Gauge test and figure out thread.

M12 VS M12*1.25 , different thread pitch different thread , can not combine together .

How to confirm metric thread ?

To check a metric thread:

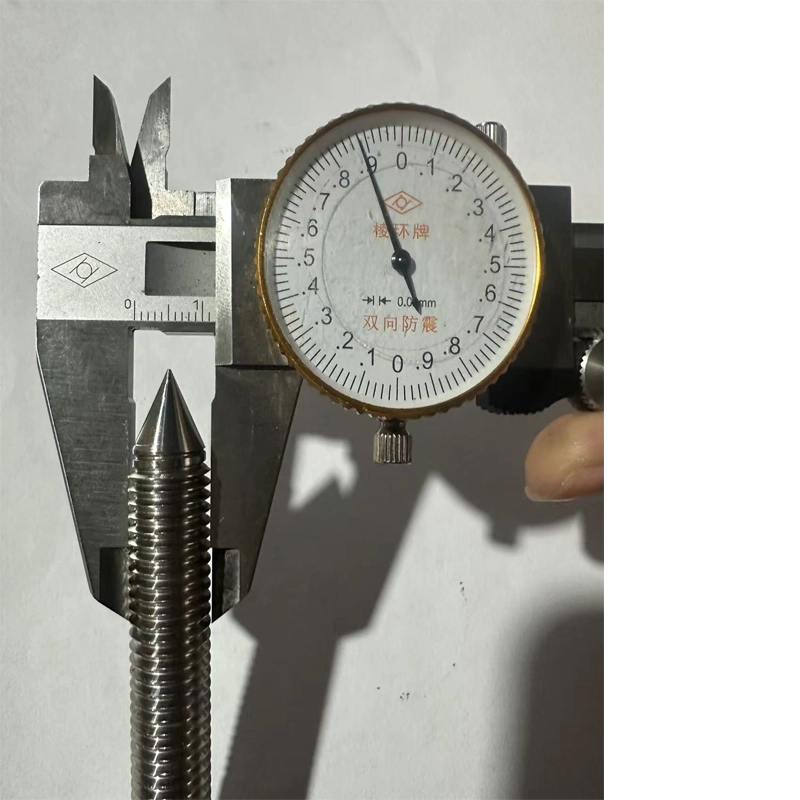

1-Measure the external diameter of the thread using a caliper.

2-Inspect the pitch, thread angle, and minor diameter with a profile projector or a thread pitch gauge.

3-Refer to a metric thread chart to confirm the thread size and specifications.

Common Mistakes When Identifying Metric Threads

Based on hands-on factory experience at Yuhuan Hongqian, the following mistakes are extremely common and can lead to assembly issues or thread failures if not carefully avoided:

-

Measuring Diameter Only

Many operators rely solely on the external diameter when identifying threads. However, this approach is insufficient because threads with the same diameter can have different pitches. Ignoring the pitch often results in selecting the wrong thread type, leading to poor fit, stripped threads, or assembly difficulties. Accurate identification requires checking both diameter and pitch using calipers, pitch gauges, or thread charts. -

Confusing Metric Threads with Pipe Threads

A frequent mistake is assuming that metric threads function like pipe threads. Unlike tapered pipe threads (NPT/BSPT), metric threads are not designed to seal on the thread itself. Using a metric thread in a fluid or gas system intended for pipe threads can cause leaks and mechanical failure. It is essential to distinguish between mechanical fastening threads and sealing pipe threads. -

Assuming All M10 Threads Are the Same

Not all M10 threads are identical. Variants such as M10×1.5, M10×1.25, and M10×1.0 differ in pitch and intended applications. Coarse threads (M10×1.5) are suitable for general fastening and quick assembly, while fine threads (M10×1.25 or M10×1.0) provide higher precision, stronger locking, and are often used in thin-walled or high-strength assemblies. Misidentifying these threads can lead to improper fastening or mechanical failures. -

Ignoring Surface Treatment Effects

Surface treatments such as plating, anodizing, or coating can alter the effective dimensions of threads, particularly fine-pitch threads. Even a thin layer of coating may affect thread fit, torque requirements, and engagement quality. Overlooking these effects can result in tight or loose fits, galling, or difficulty in assembly. Always account for coatings when measuring threads and selecting fasteners.

Metric Thread vs Pipe Thread (Important Clarification)

Metric threads are straight threads designed for fastening, not for sealing fluids or gases.

Pipe threads such as BSPP (G) or NPT rely on:

-

Taper

-

Thread deformation

-

Sealant or O-rings

Metric threads typically require:

-

Washers

-

Gaskets

-

O-ring face seals

At Yuhuan Hongqian, we often clarify this difference for customers who mistakenly request “metric pipe threads,” which do not exist as a standard category.

FAQ – Metric Thread Basics

What is a metric thread?

A metric thread is a screw thread defined in millimeters, standardized under ISO, and widely used in CNC machining and mechanical assembly.

Does M10 mean a 10mm thread?

Yes. M10 means the nominal diameter is 10 mm.

What does M10×1.5 mean?

It means a 10 mm diameter metric thread with a 1.5 mm pitch.

Are metric threads interchangeable with NPT?

No. Metric threads and NPT threads differ in angle, pitch system, and sealing method.

How do I correctly identify a metric thread?

Measure both diameter and pitch using calipers and a thread pitch gauge.

Conclusion

Understanding metric thread designations such as M10, M12, and M10×1.5 is essential for correct machining, assembly, and product reliability. While the markings may look simple, incorrect interpretation can lead to thread damage, leakage, or assembly failure.

As a CNC machining factory, Yuhuan Hongqian emphasizes practical, functional understanding of threads rather than assumptions. Always verify diameter and pitch, consult a reliable metric thread chart, and ensure compatibility before production or assembly.