The process flow of CNC lathe machining parts usually includes the following steps:

First, drawing review and process analysis

Drawing review:

Carefully review the machining drawings of parts to ensure the accuracy and completeness of the drawings.

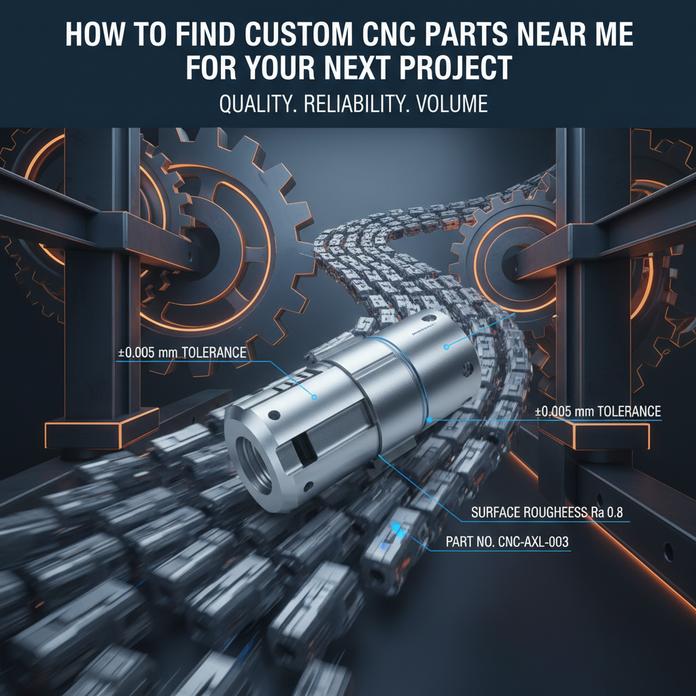

Analyze the machining requirements of the parts, including size, shape, accuracy, surface roughness, etc.

Process analysis:

Determine the CNC turning content of the part.

Analyze part drawings, including dimensioning methods, contour geometry elements, accuracy and technical requirements.

Select the appropriate clamping method, tool, cutting amount, etc.

Second, program preparation and verification

Programming:

According to the result of process analysis, the NC machining program is written using the specified code and program format.

Procedures should include rough machining, semi-finishing, finishing and other steps to meet the processing requirements of drawings.

Program check:

Verify the written program to ensure the correctness and feasibility of the program.

It is possible to check whether the machining path and cutting parameters are reasonable by simulating the operation program.

Third, processing preparation

Machine tool preparation:

Start the machine tool and check whether the functions of the machine tool are normal.

Establish a moving reference for each coordinate of the machine tool.

Tool preparation:

According to the results of process analysis, the appropriate tool is selected and installed on the machine tool.

Perform tool to tool operation to ensure tool accuracy and stability.

Workpiece clamping:

The workpiece is mounted on the machine to ensure accurate positioning and reliable clamping of the workpiece.

According to the result of process analysis, the coordinate system and zero point of the workpiece are determined.

Fourth, the processing process

Program input and startup:

Input the written program into the CNC unit.

Start the program and begin the process.

Processing monitoring:

In the process of processing, real-time monitoring of the running state of the machine tool and processing quality.

If any abnormal situation is found, it should be stopped immediately for inspection and processing.

Cutting parameters adjustment:

According to the actual situation in the machining process, timely adjust the cutting parameters (such as the amount of back cutting tool, spindle speed, feed speed, etc.) to optimize the machining effect.

Fifth, processing and testing

Processing completed:

When the program is finished, the machine will automatically stop processing.

Turn off the machine power and remove the finished parts.

Quality inspection:

Quality inspection of the finished parts, including dimensional accuracy, shape accuracy, surface roughness, etc.

If quality problems are found, the reasons should be analyzed and corresponding measures should be taken to improve.

Sixth, document preparation and archiving

Documentation:

Prepare NC machining technical documents, including process analysis report, program preparation description, machining process records, etc.

File archive:

The prepared documents will be archived and saved for subsequent reference.

To sum up, the process flow of CNC lathe machining parts is a complex and fine process, which requires the operator to have rich experience and professional knowledge. Through strict process analysis, program development and verification, processing preparation, processing process monitoring and quality inspection, we can ensure that the parts meet the requirements.