1.Introduction: Why CNC Turning is Essential for Pipe Fittings

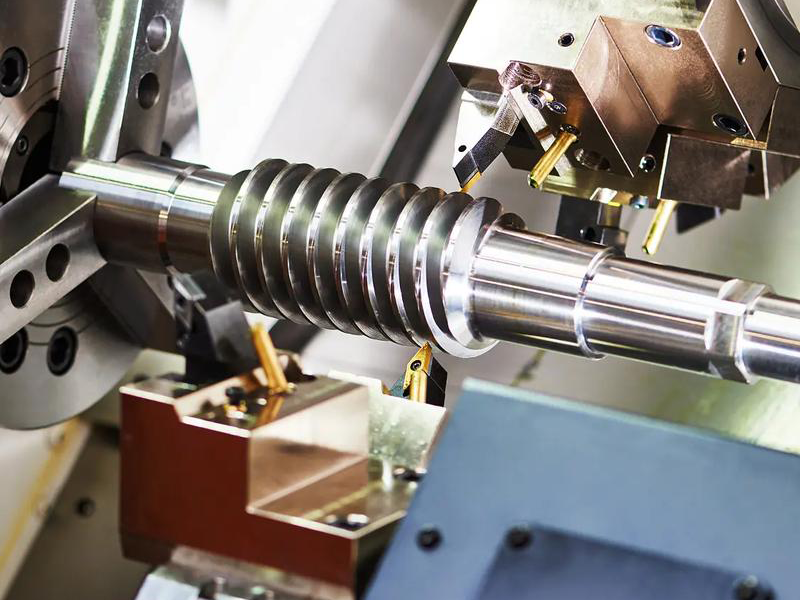

In the industrial supply chain, the term “pipe fitting” covers a vast range of components. However, for high-pressure or high-precision environments like hydraulic systems and aerospace, standard cast fittings are insufficient. This is where a professional CNC turning parts manufacturer becomes indispensable. By utilizing advanced CNC lathes, manufacturers can achieve a tolerance of 0.02mm, ensuring leak-proof connections in the most demanding applications.

2. Comprehensive Material and Thread Standards

As a dedicated pipe fitting manufacturer, Yuhuan Hongqian offers a diverse range of materials and thread profiles to meet international procurement standards.

Key Materials:

-

Stainless Steel Pipe Fittings: Grades 201, 304 pipe fitting, and 316 for superior corrosion resistance.

-

Carbon Steel pipe fittings: Q235, ANSI 1020, 1045, and high-strength 42CrMo for heavy-duty industrial use.

Global Thread Expertise:

We provide full compatibility with global piping systems, including:

-

NPT & BSPT: Tapered threads for high-pressure seals.

-

BSP (G), METRIC, UNF, UNEF: Parallel threads for mechanical fastening and hydraulic adapters.

3. Product Range: From Adapters to Flanges

Our 80 CNC lathe machines are optimized for a wide array of geometries:

-

Elbows & Tees: Directional flow components.

-

Reducers & Unions: Connecting different pipe sizes and facilitating easy maintenance.

-

Adapter Fittings & Bulkhead Fittings: Crucial for complex hydraulic and gas layouts.

-

Flanges: Ensuring secure, bolted connections.

4. Quality Control & Technical Value-Add

Procurement managers prioritize reliability. We provide a full suite of quality assurance services:

-

Advanced Testing: Optical projectors for dimensional accuracy and spectrometers for chemical composition analysis.

-

Post-Processing: Heat treatment (for hardness), demagnetization (for sensitive electronics), and laser marking for traceability.

-

Documentation: Every order includes a material test report, dimension report, and hardness inspection data.

5. Case Study: Solving the “Damaged Thread” Problem

One of the most frequent complaints in the stainless steel pipe fittings industry is thread damage during shipping or handling. At Yuhuan Hongqian, we have developed a specialized “re-threading” protocol. By using precision insert tools, we can recalibrate bumped threads without compromising the part’s integrity, ensuring smooth rotation and perfect fitment upon arrival.

6. Technical Comparison Table

| Feature | CNC Machined Fittings (Yuhuan Hongqian) | Standard Cast Fittings |

| Tolerance | ±0.02mm | ±0.3mm – 0.5mm |

| Material Density | High (Solid Bar Stock) | Low (Potential Porosity) |

| Customization | High (OEM Custom Service) | Low (Requires Molds) |

| Thread Precision | Mirror Finish / Sharp | Rough / Cast Profile |

7. FAQ about Yuhuan Hongqian

Q: How much experience does Yuhuan Hongqian have?

A: We have over 8 years of experience in the industry, operating 80 high-speed CNC lathes to ensure quality and lead time.

Q: Do you offer OEM custom pipe fitting services?

A: Yes, we specialize in custom designs for automotive, valve systems, and HVAC applications based on customer drawings.

Pofessional supply different types of pipe fitting , include adapter fittings, elbow fittings, tee , pipe uinion etc .

Q: What is your primary industry focus?

A: Our parts flow into automotive components, hydraulic systems, aerospace, and gas pipeline systems.