Introduction

When sourcing CNC turning parts, procurement engineers and buyers are not only looking for a machining process — they are selecting a reliable CNC turning parts manufacturer that can consistently deliver stable quality, controlled tolerances, and dependable lead times. CNC turning remains one of the most widely used machining processes in industrial manufacturing due to its efficiency in producing rotationally symmetrical components with high dimensional accuracy.

As a professional CNC turning parts factory and supplier, we specialize in manufacturing custom and OEM CNC turning parts primarily from carbon steel and stainless steel, with selected production of copper and aluminum fittings for specific applications. Our machining capability is designed to meet industrial tolerance requirements up to ±0.01 mm, supported by in-process and final inspection using optical projectors, micrometers, calipers, depth gauges, and pneumatic measuring instruments.

This article explains what parts CNC turning can manufacture, how to determine whether turning is the right process for your components, and what procurement teams should evaluate when selecting a CNC turned parts manufacturer.

What Is CNC Turning?

CNC turning is a subtractive machining process where a workpiece rotates at controlled speed while a stationary cutting tool removes material along the outer diameter (OD), inner diameter (ID), or face of the part. The process is executed on CNC lathes or turning centers programmed using CAD/CAM systems.

Unlike CNC milling — where the cutting tool rotates — CNC turning relies on the rotation of the raw material itself. This makes it especially suitable for producing round, cylindrical, and axially symmetrical CNC machining turning parts with consistent concentricity and surface finish.

Typical CNC turning operations include:

- External and internal turning

- Facing

- Boring

- Thread cutting

- Grooving

- Chamfering

- Drilling and tapping (with live tooling)

You can study the video for a more detail understand .

Modern CNC turning machines allow multiple operations in a single setup, reducing handling errors and improving production efficiency — a key reason procurement teams often choose CNC turning for high-volume or repeat-order components.

What Kind of Parts Are Made by CNC Turning?

Not every component is suitable for CNC turning. From a manufacturer’s perspective, CNC turning is most effective when parts meet the following criteria:

1. Overall Rotational Symmetry

While certain non-symmetrical features can be added using live tooling, the main geometry must be symmetrical around a central axis. This is fundamental to how turning machines operate.

2. Cylindrical or Round Geometry

CNC turning excels at producing parts with round outer diameters, internal bores,groove, tapers, and stepped profiles. Especially suitable for thread ,such as Metric thread, NPT thread , NPTF ,BSPP ,BSPT etc ,

Therefore Parts that are square or complex 3D shapes are generally better suited for CNC milling.

3. Material Forms for CNC Turning

In practice, CNC turning is not limited to round bar stock or tubing. Our factory routinely machines components from a variety of starting materials, including round bars, hex bars, cold-forged blanks, stamped or punched shapes, and cold-headed parts. Using advanced CNC lathes and precise fixturing, these diverse forms can be clamped securely, machined efficiently, and held to tight tolerances. This flexibility allows us to handle a wide range of parts, from standard cylindrical components to more complex or irregular shapes, without compromising quality or dimensional consistency.

Types of Parts Made by CNC Turning (By Industry)

As a CNC turning parts supplier, we routinely manufacture a wide variety of components for different industries. The table below outlines common applications:

| Industry | Typical CNC Turning Parts |

|---|---|

| Automotive | Shafts, axles, bushings, threaded fittings, bushings, gaskets |

| Industrial Machinery | Couplings, rollers, hubs, spacers, flanges, adapter fittings |

| Oil & Gas | Carbon steel fittings, valve stems, connectors, pipe fittings, hydraulic fittings |

| Construction | Bolts, studs, screws, nuts, welding parts, custom fasteners |

| Energy | Rotors, shafts, cylindrical connectors, flanges |

| Electronics | Precision pins, terminals, housings |

| Marine | Stainless steel shafts, couplings, flanges |

| General Manufacturing | OEM custom CNC turning parts, barbed hose fittings, pneumatic fittings, adapter fittings |

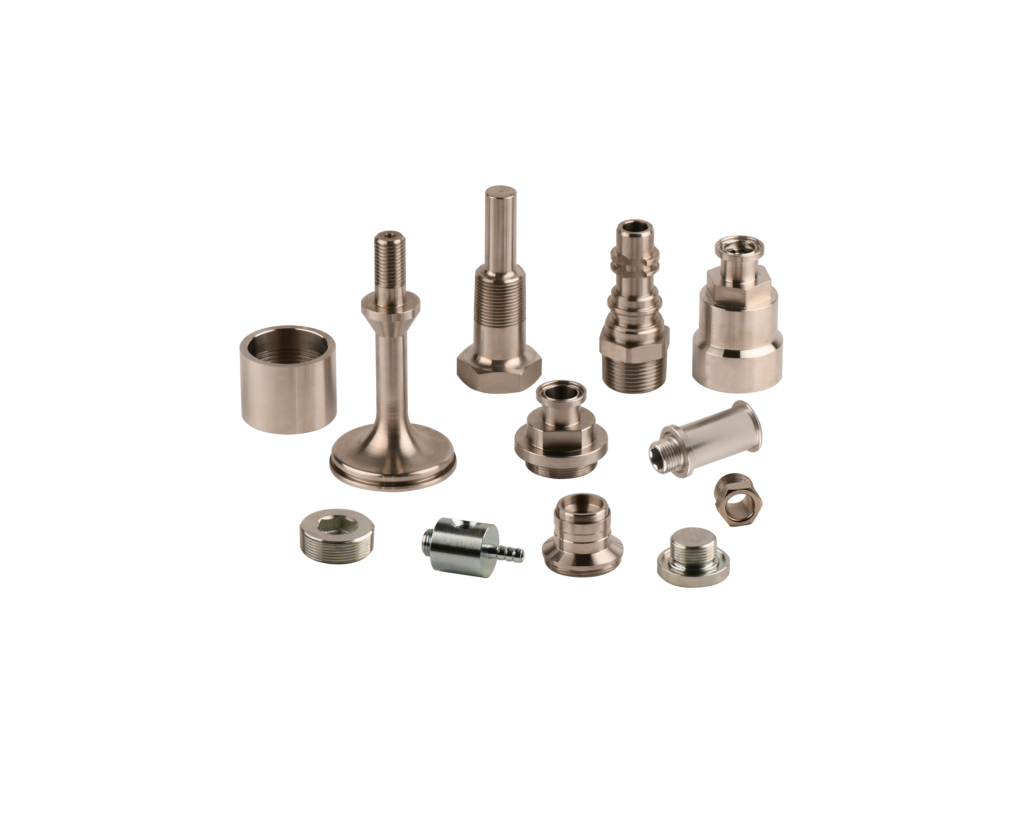

CNC Turned Industrial Fittings and Mechanical Components

Our CNC turning factory specializes in the production of high-precision industrial fittings and mechanical components for OEM and custom applications. With a strong focus on carbon steel and stainless steel, and selected production in copper and aluminum, we provide components that meet demanding industrial requirements for dimensional accuracy, thread quality, and sealing reliability.

Our main CNC turned parts include:

-

Pipe fittings – precision cylindrical connectors for industrial piping and fluid systems.

-

Steel fittings – durable, high-strength fittings for structural and pressure applications.

-

Hydraulic fittings – components designed to withstand high-pressure conditions in hydraulic systems.

-

Pneumatic fittings – fittings for air-driven systems, requiring tight tolerances and leak-free performance.

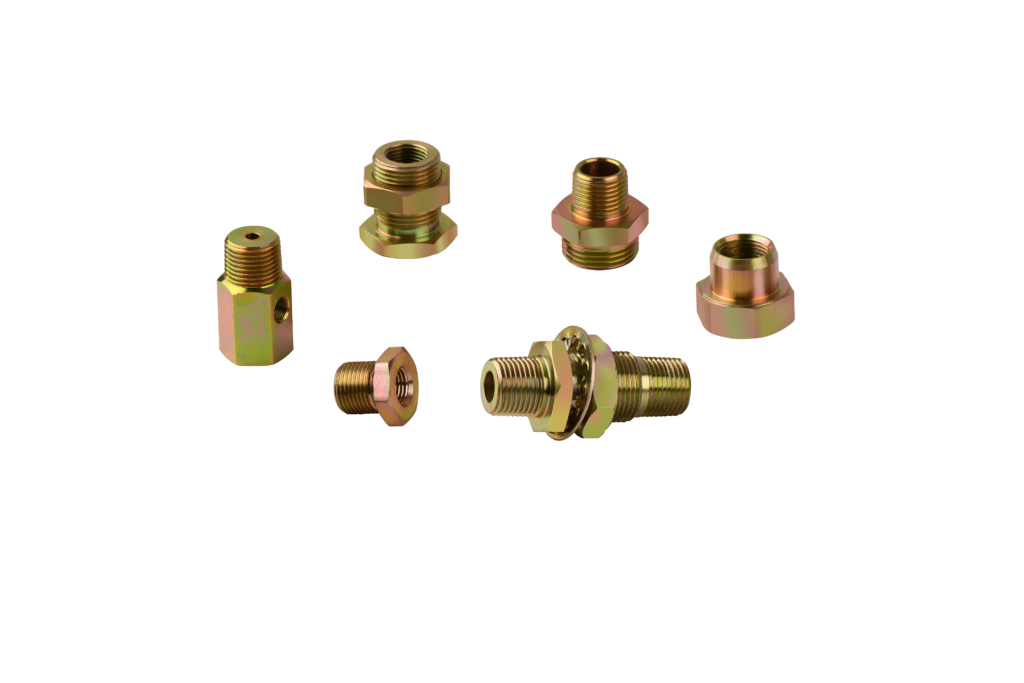

-

Bulkhead fittings – panel-mounted connectors for fluid, gas, or hydraulic applications. The most common size is 1-14″ ,1/2-14npt,3/8-18 NPT,3/4-16UNF etc.

-

Elbow and adapter fittings – angled or transition fittings ensuring smooth flow and reliable alignment.

-

Barbed hose fittings – controlled barb profiles to secure hoses in industrial and fluid systems.

-

Nuts and bolts, screws, and other fasteners – standard and custom components with precise threads and consistent mechanical performance.

-

Bushings and gaskets – precision cylindrical or flat components for friction reduction, alignment, or sealing.

-

Shafts and flanges – critical rotational and connecting components for machinery, pumps, and piping systems.

-

Welding parts – CNC-prepared components ready for welding assemblies with accurate critical dimensions.

Based on the list of our business type you can contact us .

Our CNC Turning Factory Capabilities

Our factory with 80 CNC lathes, a 2,000 m² production facility, and 30 skilled operators, we have more than 8 years cnc turning experience with produce different type steel fitting and ss fittings . Especially in pipe joint , bulkhead fitting ,adapter fitting etc.

We have the test machine of optical projectors, micrometers, calipers, depth gauges, and pneumatic measuring instruments to control the precisoin size and could satisfyu customer high tolerances up to ±0.01 mm. This ensures that all CNC turned fittings, shafts, and fasteners meet industrial standards and customer specifications, providing a reliable source for OEM, custom, and bulk orders.

By sourcing from a trusted CNC turning parts manufacturer and supplier, procurement teams can secure consistent quality, on-time delivery, and cost-effective production for all types of mechanical and fluid system components.

How to Determine Which Parts Are Best Made by CNC Turning

At our CNC turning factory, the decision of which parts to machine starts with geometry and rotation. Parts that rotate during operation or require precise coaxial alignment—such as shafts, bushings, and flanges—are ideal candidates. CNC turning naturally produces the roundness and concentricity these components demand.

Cylindrical or irregular bar forms can all be handled in our workshops. We mainly produce steel fitting by round bars, hex bars, tube ,cold–headed blanks, and hot forging blank, giving us flexibility beyond simple bar stock. We can supply the cnc parts based on the drawing design , and provide most economy way to catch order.

Complex features—like internal threads, grooves, and drilled holes—can often be completed in a single setup with our live tooling lathes. This reduces handling errors and helps maintain consistent tolerances across the batch.

Material choice is also crucial. Our CNC turning capabilities cover:

-

Carbon steel: low, medium, and high carbon steels for structural and pressure parts

-

Stainless steel: 303, 304, 316, and other grades for corrosion-resistant components

-

Copper and aluminum: selected for fittings, bushings, and lightweight applications

These materials are chosen for their machinability and stable surface finishes, ensuring the parts meet industrial standards.

Finally, CNC turning is cost-effective and efficient for medium to high-volume production. With precise tooling, fast setup, and in-process inspections using micrometers, optical projectors, and depth gauges, we maintain tolerances up to ±0.01 mm—even without CMM systems. This approach guarantees that every batch of fittings, screws, shafts, and gaskets is ready for OEM assembly or custom applications.

What materials are best for CNC turning parts?

Carbon steel and stainless steel are the most commonly used due to strength, machinability, and cost balance. It is also suitable to produce by brass and aluminum mateiral by cnc lathe machine .

What tolerances can CNC turning achieve?

As a cnc turning parts factory , our Standard industrial CNC turning can reliably achieve ±0.01 mm with proper tooling and inspection.

Is CNC turning suitable for custom parts?

Yes. CNC turning is widely used for custom and OEM cnc parts, especially cylindrical components.

How does CNC turning differ from CNC milling?

Turning rotates the workpiece, milling rotates the cutting tool. Turning is more efficient for round parts.

Can CNC turning handle threads and grooves?

Yes. The advantage of cnc turning is external and internal threads, grooves, and chamfers are standard turning features.

Is CNC turning cost-effective for small batches?

For rotational parts, CNC turning remains cost-effective even in small to batch quantities .Cnc milling tool , cost , mould is more expensive compare cnc turning .