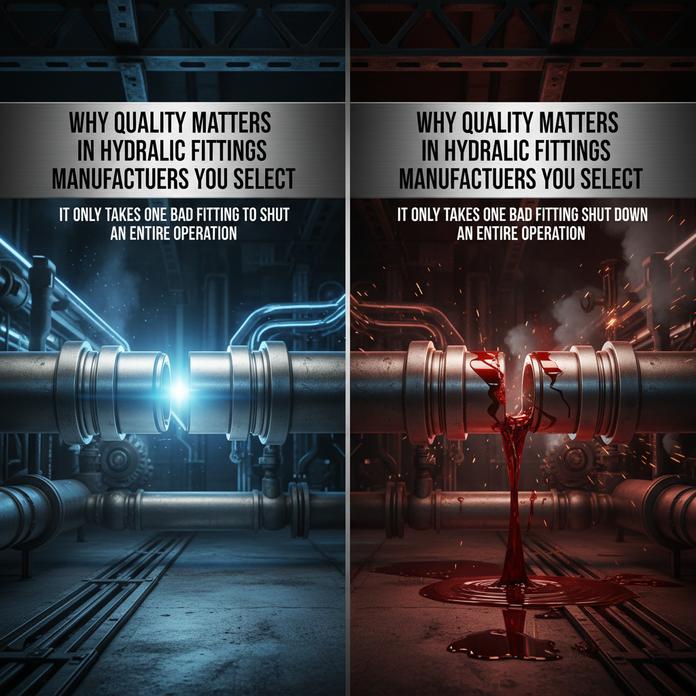

Hydraulic fittings manufacturers aren’t all cut from the same cloth—cut corners, cheap metals, and sloppy threads can turn a multi-million-dollar system into a glorified sprinkler. And when you’re ordering by the truckload, that’s not just frustrating—it’s dangerous.

One project manager at Yuhuan Hongqian summed it up perfectly: “It only takes one bad fitting to shut down an entire operation. We build like lives depend on it—because sometimes they do.” [2024 Field Operations Report – Yuhuan Hongqian]

Think of your hydraulic system like a circulatory system. If the veins (your hoses) are solid but the joints leak? You’re in trouble. Pressure drops, efficiency nosedives, and maintenance calls start stacking up faster than invoices.

So before you pick a partner based on price tags alone, stick around—we’re breaking down what quality really means when you’re buying thousands of parts that can’t afford to fail.

Why Quality Matters in Hydraulic Fittings

Choosing the right quality in hydraulic fittings isn’t just smart—it’s survival. Let’s break down what makes top-tier fittings worth every penny.

Material integrity

• Stainless steel, Carbon steel, and Duplex steel are not created equal—each shines under different stress points.

• Durability comes from more than just thickness; it’s about chemical makeup and resistance to fatigue.

• In high-pressure systems, material failure isn’t an option—only metals with proven material strength and tested corrosion resistance survive long-term.

• If a fitting cracks under pressure, your entire system could fail. That’s why serious hydraulic fittings manufacturers prioritize integrity over cost-cutting shortcuts.

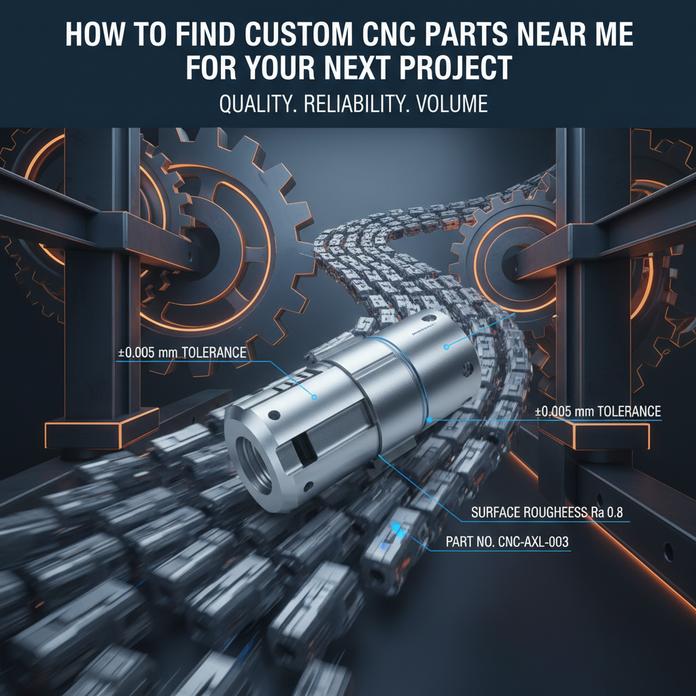

Precision machining

- Tight tolerances aren’t just a brag—they’re the backbone of leak-proof performance.

- Every curve on an elbow fitting, every junction on a tee fitting, and every thread on a union fitting must be machined to perfection.

- Poorly cut threads or misaligned angles? Say goodbye to pressure containment.

- High-end shops use CNC lathes that hit micrometer-level accuracy, ensuring unmatched machining accuracy and consistent manufacturing across all types of fittings.

- No matter how good your materials are, if the machining is off, you’ve got problems waiting to happen—especially with demanding fluid systems.

Certified compliance

① ISO standards cover everything from dimensional specs to burst pressure thresholds—non-negotiable for global trade.

② SAE standards dive into specifics like thread forms and sealing methods tailored to North American systems.

③ ASTM standards ensure metallurgical consistency across different production batches.

Only certified fittings pass testing protocols that simulate real-world abuse—from vibration fatigue to salt spray corrosion cycles. That’s why reliable hydraulic fittings manufacturers never skip compliance—they know it means fewer call-backs, safer installs, and peace of mind in mission-critical ops.

Built for applications

✔️ In oil rigs where downtime costs millions per hour, you need fittings built to thrive in salty air and extreme heat.

✔️ For mobile hydraulics like excavators or cranes, vibration resistance is everything—flexible yet tough connections are key here.

✔️ Inside chemical plants or refineries? Corrosive fluids demand ultra-high-performance materials engineered precisely for aggressive media handling.

✔️ Even water-based hydraulic systems can become corrosive over time without proper alloy selection—don’t let “just water” fool you into cheaping out.

Each application has its own quirks—and only purpose-built components ensure long-term reliability across all kinds of environments that modern fluid transfer systems face daily.

Summary: Why quality isn’t optional

Quality isn’t some luxury add-on when it comes to hydraulic components—it’s baked into how they function under stress, heat, vibration, and time itself. From choosing the right metal alloy to ensuring precise thread alignment—all these details separate pro-grade solutions from ticking time bombs in your system design.

That’s why experienced buyers don’t just Google “hydraulic fittings manufacturers” once—they dig deep into specs, certifications, and build philosophy before placing their trust in any supplier—even if that supplier happens to be yuuhuan hongqian just once by name here.

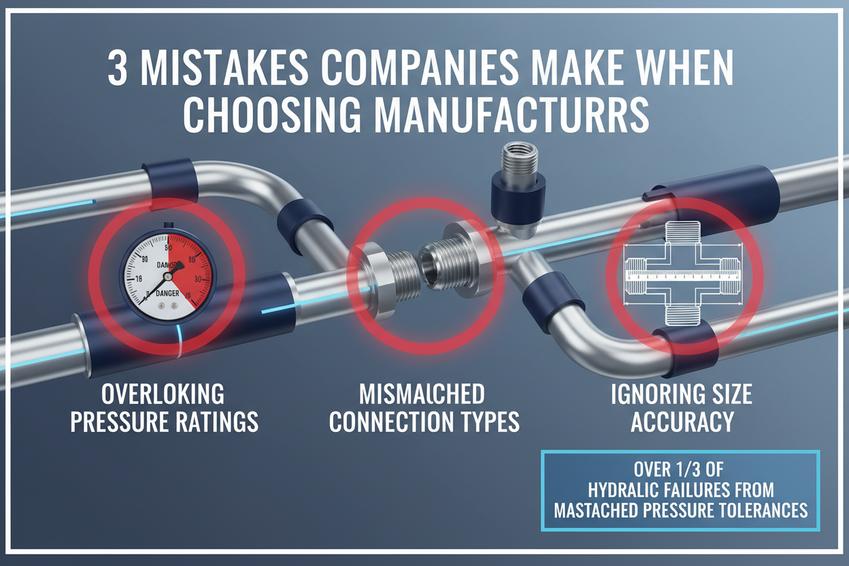

3 Mistakes Companies Make When Choosing Manufacturers

Choosing the right hydraulic fittings manufacturers isn’t rocket science, but it’s not a cakewalk either. Here’s where most folks mess up.

Overlooking pressure ratings

• Ignoring pressure rating specs can blow your system—literally.

• Not all fittings are built for high PSI, especially in extreme industrial setups.

• Always compare working pressure vs. burst pressure before signing off on components.

A lot of companies get too comfy assuming all fittings handle the same load. But real-world conditions fluctuate. For example, a fitting rated for just under 3000 PSI won’t survive in a pipeline spiking past 10000 PSI during peak hours. According to Fluid Power Journal’s Q2 report in early 2024, over one-third of hydraulic failures stemmed from mismatched pressure tolerances.

Mismatched connection types

Different threads don’t play nice together:

- NPT threads may look similar to BSP but differ in pitch and angle—leading to leaks.

- Using a JIC flare with incompatible tubing? That’s asking for trouble.

- Assuming “close enough” is good enough? It isn’t when fluid starts spraying.

Compatibility between thread types like BSP threads, JIC flares, and tapered connectors is critical for safety and sealing integrity in high-pressure environments. Even seasoned engineers sometimes overlook these nuances when sourcing from new or overseas suppliers—especially when comparing multiple hydraulic fittings manufacturers without checking their standardization practices.

Ignoring size accuracy

✱ Size matters more than you think—especially in tight systems with no room for error.

✱ A misjudged diameter on an adapter can throw off the entire flow rate or cause backpressure issues.

Precision machining ensures that every thread and bore aligns perfectly across components like elbows, tees, and reducers. Minor deviations outside proper dimensional tolerance can cause major headaches later—from vibration-induced loosening to complete fitting failure under stress.

Scientific comparison: Pressure ratings vs application types

| Application Type | Typical Working PSI | Required Burst PSI | Recommended Fitting Rating |

|---|---|---|---|

| Agricultural Sprayers | 1500 | 4500 | >5000 |

| Construction Vehicles | 3000 | 9000 | >10000 |

| Industrial Presses | 4000 | >12000 | >15000 |

| Marine Hydraulics | ~2500 | ~7500 | >8000 |

When evaluating different hydraulic fittings manufacturers, always align your application’s needs with certified specs—not just catalog numbers.

Multiple short reminders about manufacturer selection fails

- Don’t assume all manufacturers test beyond minimum safety thresholds.

- Watch out for inconsistent measurement systems—imperial vs metric confusion is still common.

- Ask vendors how they validate their thread compatibility standards before purchase.

Choosing the wrong manufacturer because they looked “reliable enough” on paper is like buying shoes based solely on color—you’ll end up limping through production downtime or worse, facing total system failure mid-operation.

Grouped checklist: What smart buyers actually verify

✅ Pressure compatibility:

- Max operating PSI vs component rating

- Margin above burst threshold

✅ Thread matching:

- Correct use of NPT/BSP/JIC standards

- Avoiding cross-threading risks

✅ Dimensional accuracy:

- Tolerance levels within ±0.01 inch

- Fitment testing during prototyping

✅ Manufacturer credibility:

- Do they publish tolerance specs?

- Are their certifications current?

Too many businesses skip these checks while comparing quotes from various hydraulic fittings manufacturers, only to pay double fixing things later down the line.

Real-world mishaps caused by poor sizing decisions

In early Q1 of this year, an offshore drilling operator had to shut down operations for two days after using improperly sized adapter fittings sourced from an uncertified vendor overseas. The resulting leak led to over $70K in cleanup costs—not counting lost productivity hours or reputation damage among stakeholders relying on timely delivery schedules.

Choosing reliable and precise-fitting components isn’t just about ticking boxes—it’s about knowing what those boxes mean before trusting someone else’s label over your own system requirements.

And yes—it helps if your supplier knows what they’re doing too… even if it means calling up yuuhuan hongqian once instead of three other unknowns who can’t tell BSPT from NPTF blindfolded.

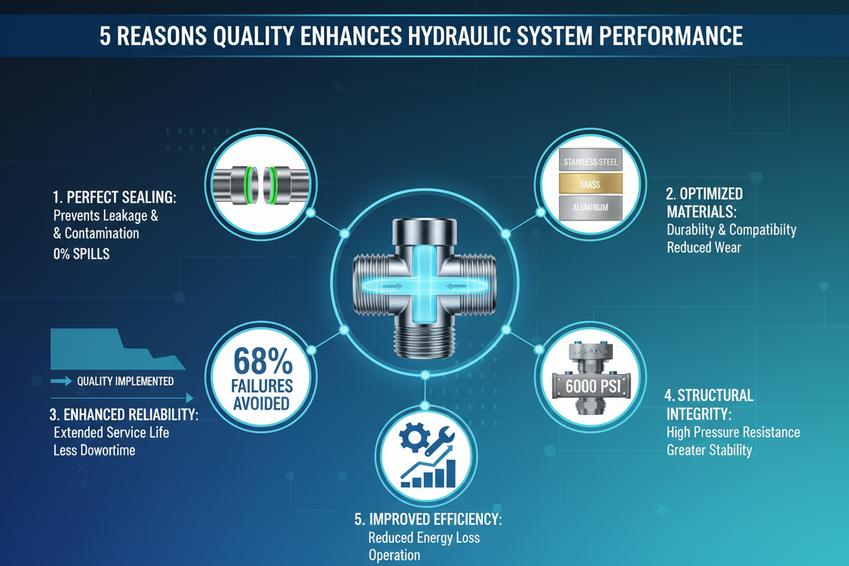

5 Reasons Quality Enhances Hydraulic System Performance

When it comes to fluid systems, quality isn’t just a buzzword—it’s the backbone of performance. Here’s how top-tier components keep your machinery running like clockwork.

Consistent flow control

- Precision-made hydraulic couplings and flange connections are the unsung heroes of steady operation.

- Without tight tolerances in precision fittings, you get turbulence, pressure drops, and erratic behavior.

- Smooth internal surfaces improve fluid dynamics, cutting down on flow resistance and energy waste.

- Systems with optimized connection integrity reduce noise and heat buildup—two big enemies of efficiency.

- That’s why savvy buyers trust high-end parts from reliable hydraulic fittings manufacturers—they’re not just buying metal; they’re buying stability.

Reduced leakage

- Leaks don’t just waste fluid—they wreck uptime. That’s why high-grade sealing solutions, like molded O-rings, matter so much.

- In both pneumatic systems and water lines, even minor seepage can trigger corrosion or system failure fast.

- Top-tier fittings maintain total system integrity, keeping everything locked tight under stress.

- Quality parts deliver true leak-free operation, even under frequent pressure cycling—cheap ones? Not so much.

Material optimization

| Material Type | Corrosion Resistance | Strength Rating | Common Use Case |

|---|---|---|---|

| Brass Alloys | High | Medium | Water & Air Lines |

| Aluminum Alloy | Moderate | High | Lightweight Systems |

| Stainless Steel | Very High | Very High | Harsh Environments |

| Plastic Composites | Low | Low | Temporary Installs |

Using the right material is half the battle in long-lasting performance. Premium brands use engineered blends of brass alloys for conductivity and anti-corrosion properties, while lightweight yet strong aluminum alloy options shine in mobile equipment where weight matters. Don’t skimp here—this is where durability lives or dies.

Long-term reliability

“By 2024, over 68% of industrial failures were traced back to component fatigue caused by non-compliant parts.” – Global Machinery Insight Report

That stat says it all. When you stick with fittings certified under recognized benchmarks like DIN standards or verified through strict ANSI standards, you’re investing in real-world endurance—not guesswork. These certifications aren’t fluff; they’re battle-tested proof that your gear will keep rolling even when conditions get rough.

And if your supplier isn’t offering this kind of assurance? Time to rethink who you’re trusting with your uptime—brands like yuuhuan hongqian don’t play around when it comes to compliance and solid build quality.

Stable performance

• Pressure spikes can be brutal—but premium fittings built for up to 6000 PSI hold firm without cracking under strain.

• Whether it’s sudden load shifts or stop-start cycles, strong components ensure constant system stability across operations.

• This kind of ruggedness supports better operational safety while extending component lifespan dramatically.

From underground mining rigs to factory automation lines, staying cool under pressure starts with choosing the right gear from dependable hydraulic fittings manufacturers—and that means looking beyond price tags toward proven specs like high-end PSI ratings and tested seal strength.

FAQs about Hydraulic Fittings Manufacturers

What defines a trustworthy hydraulic fittings manufacturer?

Precision is the heartbeat here—machining elbow fittings, tee fittings, coupling fittings without burrs; matching NPT threads or JIC flares exactly to spec. Stainless steel for marine durability, carbon steel for raw strength—each material tells you if the maker understands your system’s pulse.

How does pressure rating impact real-world reliability?

When oil and gas rigs breathe at 6000 PSI—or construction hydraulics surge past 5000 PSI—ratings are life insurance. A mismatched adapter fitting can mean rapid fluid escape under high pressure; that’s why every union fitting must be tested to endure its declared load before sealing into place on-site.

Why do materials matter in large-volume purchases?

- Stainless steel: corrosion resistance for water systems or coastal pneumatic networks.

- Duplex steel: resilience where chemical exposure threatens structural integrity.

- Brass alloys & aluminum alloy: lighter yet steady for mid-range (3000–5000 PSI) fluid transfer lines in mobile hydraulic systems. The right metal turns bulk orders into decades of service rather than months of repairs.

How critical is size accuracy in adapters and couplings?

A mismatch from 1/2 inch to 3/4 inch creates uneven seals—the flow surges erratically, heating compression zones until failure brews quietly inside your lines. In tight pneumatic loops or long hydraulic runs, even a fraction-off bore pulls you closer to downtime dramas nobody wants on a Monday morning shift.

Which standards mark genuine manufacturing quality?

ISO standards demand verifiable surface finish; ASTM insists on material identity; SAE regulates dimensions so BSP-threaded elbows fit cleanly beside flange connections without grinding shock loads into the joints; DIN and ANSI keep thread geometry uniform across continents so your replacement part from another supplier doesn’t turn installation day into chaos.