In the cnc precision machining industry, achieving exact final lengths and structural integrity often requires multiple specialized processes, except cnc machining process , also relate to welding, heat treatment, and electroplating etc. Among these, welding plays a critical role in joining metal components with high accuracy, ensuring both strength and durability. For CNC machining factory in China and around the world, understanding advanced welding techniques—such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding—is essential for producing high-quality parts that meet strict tolerances and international standards. This article explores key welding methods, their applications in machining, and best practices to enhance productivity and part reliability.

What is Welding?

Welding is a fundamental metal fabrication process used in precision machining and manufacturing industries worldwide, including China’s advanced CNC machining sector. It involves joining two or more metal components by applying heat, pressure, or both, creating a strong, permanent bond. Common welding techniques include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and spot welding, each suited for different materials and production requirements. In modern manufacturing, welding ensures structural integrity, dimensional accuracy, and high-quality finishes for parts used in automotive, aerospace, construction, and machinery applications. Understanding welding processes is essential for manufacturers aiming to deliver precision CNC parts that meet international standards and strict tolerance requirements.

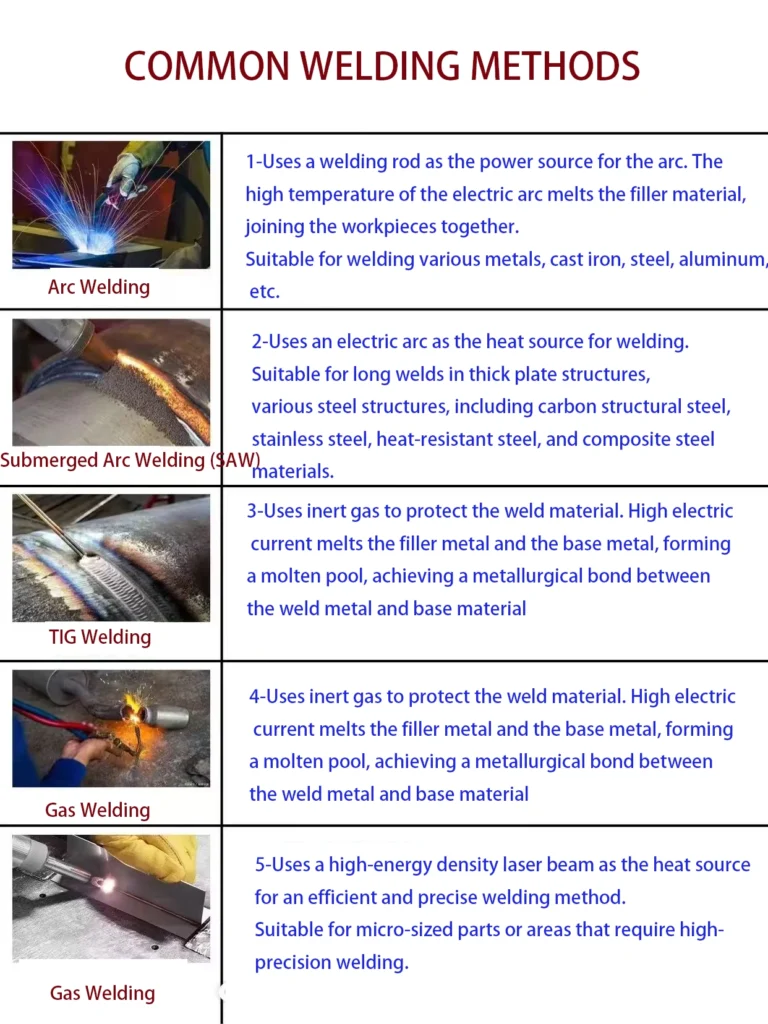

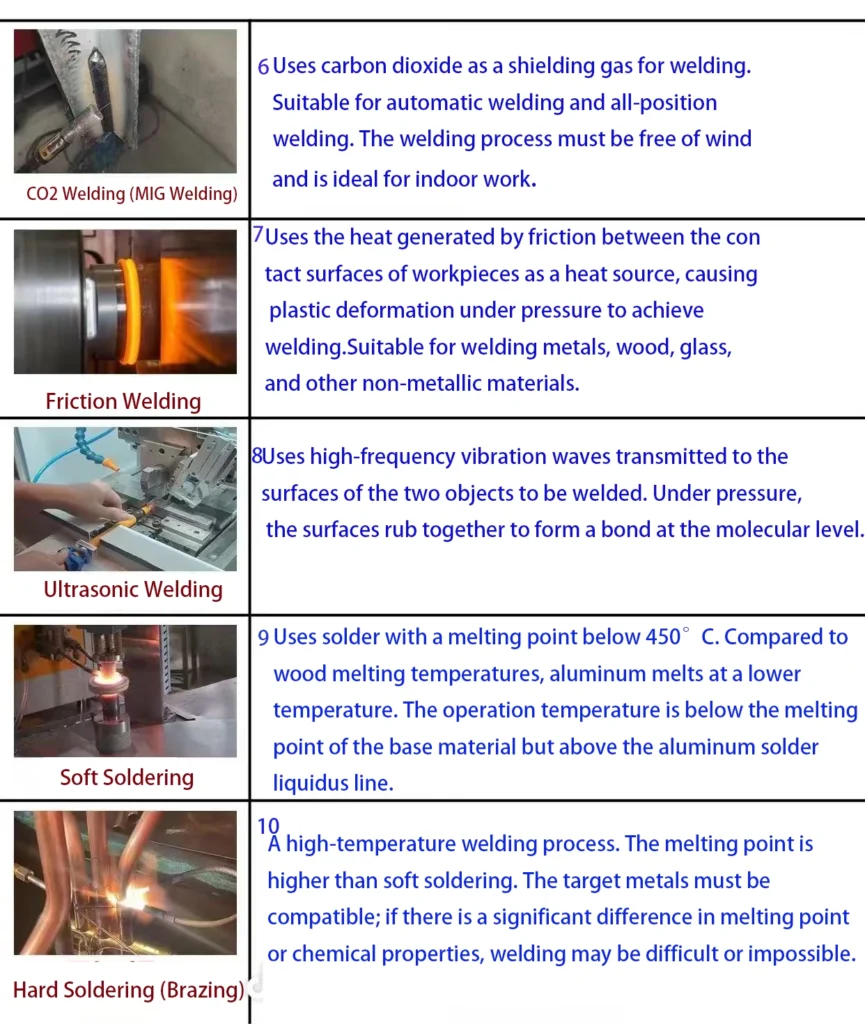

How many type of welding ?

In the CNC machining industry, the most commonly used welding processes are TIG welding and laser welding. These two methods are widely adopted because they provide excellent weld quality while maintaining precise control over heat input and dimensional stability. TIG welding is especially valued for its clean, controllable welds and is well suited for stainless steel, carbon steel, and aluminum machined parts, particularly in low-volume and custom production. Laser welding, on the other hand, offers extremely narrow weld seams and a minimal heat-affected zone, making it ideal for high-precision components, thin-walled parts, and applications with strict appearance and tolerance requirements. Together, TIG welding and laser welding enable manufacturers to achieve strong, reliable joints without compromising machining accuracy or surface finish.

Now start introduce the Tig welding for elbow fitting and shaft ,bolt tig welding detail , as follow

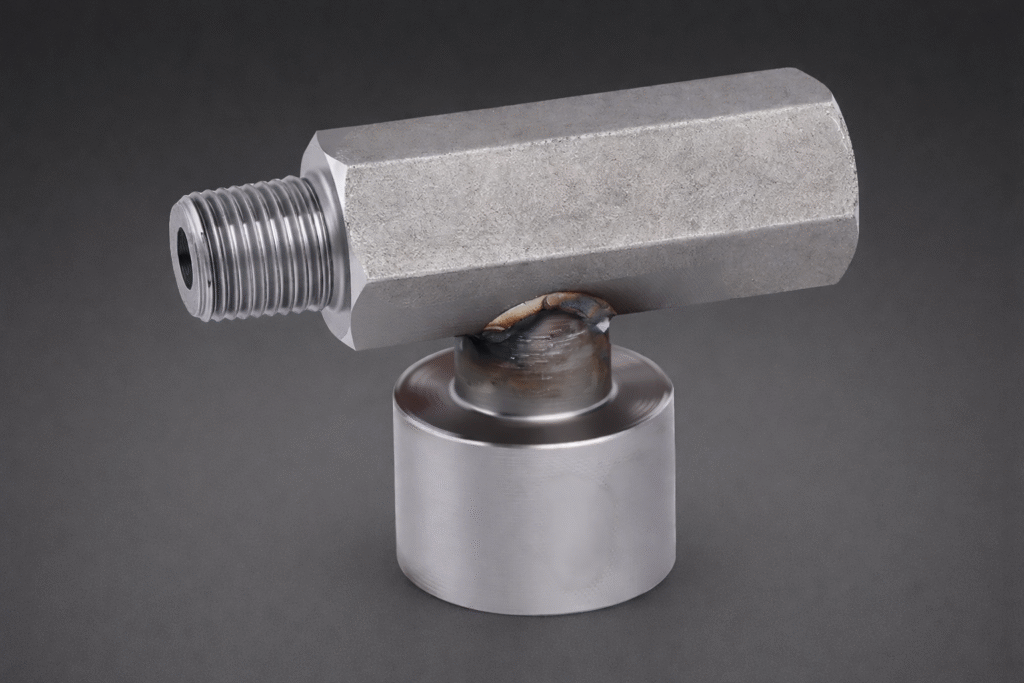

Elbow Fitting Welding in Low-Volume CNC Machining

In the precision machining industry, manufacturing elbows for piping or custom assemblies can be challenging when production volumes are low. Elbow fitting usally need satisy big quantity then could choose hot forging to produce the blank . But for customer usually choose a good supplier will choose place a trial order and small batch quantity . Weding could solve the customer trust problem to reduce trial order costs .

In such scenarios, welding becomes an efficient and cost-effective solution.

Operation Steps:

- Surface Preparation: Clean the metal surfaces to remove oil, rust, and oxidation for optimal weld adhesion.

- Alignment and Fixturing: Properly position and secure the elbow components to maintain dimensional accuracy.

- Welding Process: Use TIG or MIG welding techniques to join the parts, ensuring high precision and a smooth finish.

- Post-Weld Treatment: Depending on the application, perform grinding, polishing, or heat treatment to enhance strength and appearance.

- Quality Inspection: Check dimensional tolerances, weld penetration, and structural integrity to meet design requirements.

Best Practices:

- Maintain proper shielding gas coverage in TIG/MIG welding to prevent oxidation.

- Use clamps or jigs to avoid misalignment, especially for small-batch orders.

- Keep welding parameters consistent for repeatable quality.

This approach allows CNC machining manufacutre high-quality elbows for small-batch or prototype orders, reducing tooling costs while maintaining flexibility and short lead times.

ELBOW FITTING TIG WELDING FACTORY

Hydrostatic Testing to Ensure Quality

To further guarantee the structural integrity and safety of welded elbows, Chinese CNC machining suppliers often perform hydrostatic testing after welding and post-weld treatment. The welded elbows are gradually pressurized up to the design specifications and inspected for leaks, cracks, or weld defects. Maintaining detailed test records is especially important for small-batch or prototype orders, helping manufacturers track quality and demonstrate compliance with international standards.

Best practices for hydrostatic testing include ensuring all weld seams are smooth and free from visible defects, adjusting pressure and duration according to design requirements, and keeping records for traceability. By incorporating hydrostatic testing, manufacturers can deliver high-quality, reliable elbows suitable for small-batch production and custom piping systems.

Rod and Bolt Welding for Custom CNC Components

Another common application of welding in the machining industry involves rods, bolts, and other linear components that require custom lengths or threading. When off-the-shelf parts do not meet design requirements, welding provides a practical solution.

For a more easy understand , we can clearly see the shaft bottom is big size , top is small size . So for reduce the cost , we usally choose welding the blank first , then based on 2d drawing to cnc machining .

But the final cnc turning parts will satisfy the accurate size and no have the Weld mark . The cnc parts after cnc turning process will be smooth and shine same with the hot foring parts .

Operation Steps:

- Material Preparation: Cut rods or bolts to approximate lengths and clean surfaces to remove contaminants.

- Alignment: Use precision jigs to align rods or bolts with nuts or threaded inserts before welding. more detail you can check follow photo.

- Welding Process: Apply TIG welding for high-strength joints while maintaining dimensional accuracy.

- Post-Weld Treatment: Optionally, perform heat treatment or surface finishing to improve mechanical strength and corrosion resistance.

- Inspection: Test structural integrity, thread quality, and overall dimensional accuracy to ensure compliance with design specifications.

Best Practices:

- Always check the fit and alignment before welding to prevent rework.

- Maintain consistent heat input to avoid warping or weakening of components.

- Consider small-batch production workflows in Taiwan CNC workshops to maximize efficiency.

By combining precision CNC machining with targeted welding techniques, manufacturers can deliver tailor-made rods, bolts, and assemblies efficiently for clients in industries such as construction hardware, industrial machinery, and custom equipment.

What is laser wedling ?

Laser welding is a welding process that uses a highly focused laser beam to join metal parts together. The laser generates intense heat at a precise location, melting the base materials and forming a strong, narrow weld seam with minimal heat input.

Because the heat-affected zone is very small, laser welding causes very little distortion, making it ideal for high-precision components, thin-walled parts, and CNC-machined parts with tight tolerances. It is widely used for welding stainless steel, carbon steel, aluminum alloys, and other metals where appearance, accuracy, and consistency are critical.

In modern manufacturing, laser welding is commonly applied in industries such as CNC machining, automotive, electronics, medical devices, and precision hardware, where high-quality and repeatable welds are required.

How to choose tig welding and laser welding ?

In the cnc precision machining industry, achieving exact final lengths and structural integrity often requires multiple specialized processes, except cnc machining process , also relate to welding, heat treatment, and electroplating etc. Among these, welding plays a critical role in joining metal components with high accuracy, ensuring both strength and durability. For CNC machining factory in China and around the world, understanding advanced welding techniques—such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding—is essential for producing high-quality parts that meet strict tolerances and international standards. This article explores key welding methods, their applications in machining, and best practices to enhance productivity and part reliability.

Conclusion

In summary, welding is a crucial process in CNC precision machining, providing strong, accurate, and reliable joints that machining alone cannot achieve. TIG welding excels in low-volume production and custom components, while laser welding is ideal for high-precision, thin-walled parts. By combining the right welding method with CNC finishing and quality inspections, we can supply customer durable life cnc parts .