China high-quality precision CNC turning services you can trust. Competitive pricing and fast lead times.

Yuhuan hongqian machinery co.,ltd is a manufacture of cnc latch machines parts delivery excellent quality flexibly with more than 10 years.

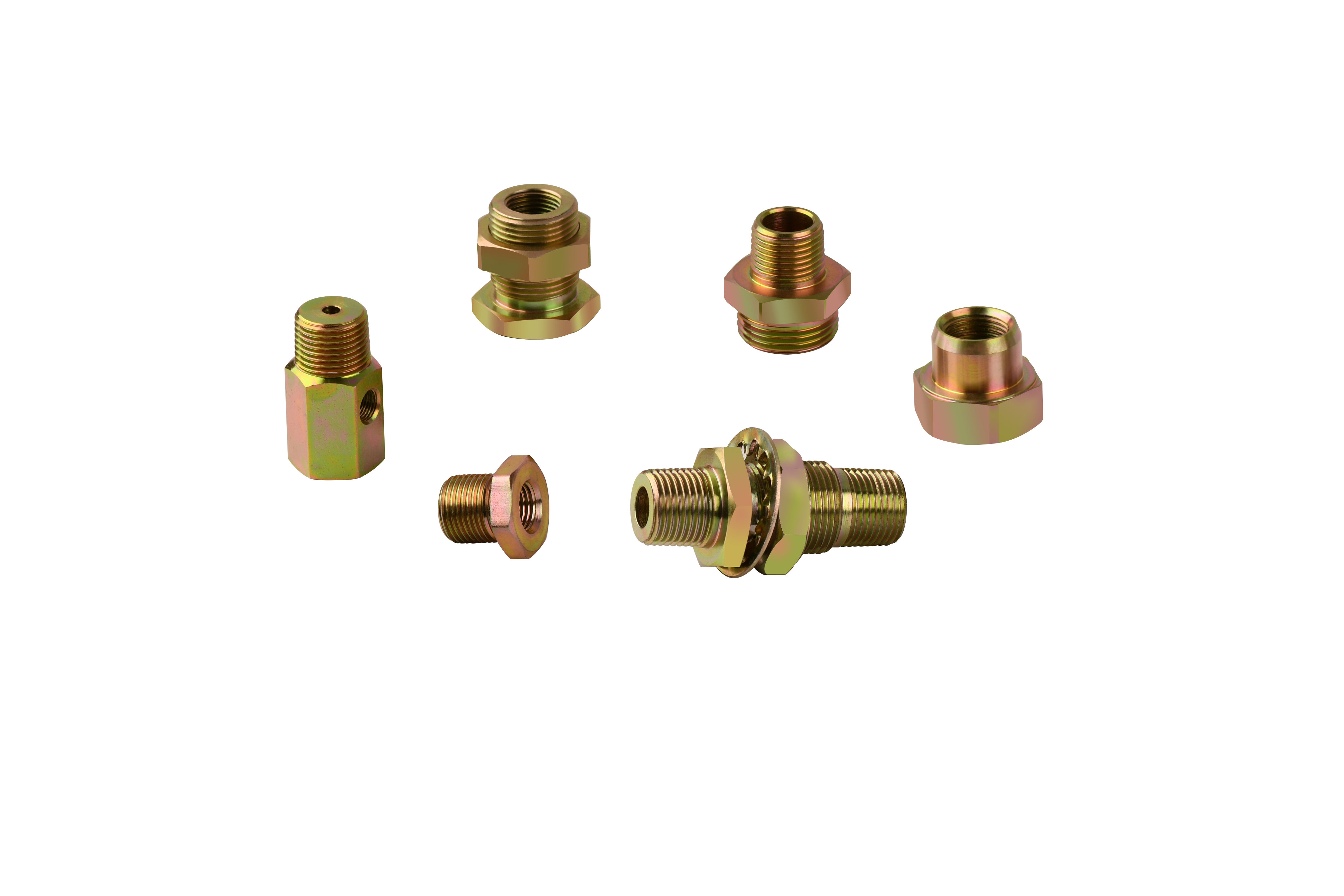

Hongqian Precision provides excellent quality CNC lathe services to United States and Europe based on the requirements to customers, featuring precision machined parts, lathe parts. Our precision CNC Turning Parts type include hex plug, hydraulic fitting , pipe joint , pipe fittings, hex nut ,fasteners,automobile parts ,gas pipe fitting,beer tap parts,valve stem ,elbow connector ,adapter fitting ,Pneumatic joint,pin, oem bolt etc by carbon steel , stainelss steel ,brass ,aluminum mateiral .

Yuhuan Hongqian offers a one-stop service that will save you both time and money. We can do various post-machining surface finish for your parts to display, and any assembly works as requested. We will deliver the parts per your custom needs.

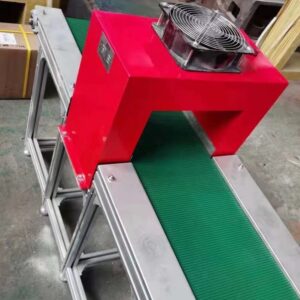

Our factory employs state-of-the-art CNC technology to ensure precision and accuracy in every turning part we produce, meeting even the most demanding specifications.

With years of experience in the industry, we have honed our skills and expertise to deliver high-quality turning parts that exceed customer expectations.

We offer competitive pricing without compromising on quality, making us the cost-effective choice for all your CNC turning needs.

Whether you need a standard turning part or a custom solution, provide cad /stp drawings or samples ,we have the capabilities to fulfill your requirements with precision and efficiency.

Quality is our top priority, and we adhere to strict quality control measures throughout the manufacturing process to ensure the highest standards of excellence.

With our commitment to quality, efficiency, and customer satisfaction, we strive to be a reliable partner for all your CNC turning needs, providing you with peace of mind and confidence in our services.

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 340 mm | 13.38 inch |

| Maximum part length | 260 mm | 10.24 inch |

| Maximum swing over the carriage | 400 mm | 15.57 inch |

| Maximum spindle through-hole | 56 mm | 2 inch |

Maximum speed: 2000RPM

Motor power: 750WYuhuan Hongqian provides precision machining for various metal materials. We specialize in processing Carbon Steel, Stainless Steel, Aluminum, and Brass, ensuring each material is treated with the correct tooling and techniques to achieve your desired specifications.

Yuhuan Hongqian can provide different surface treatments according to customer drawing information to achieve the mechanical properties desired by customers. After different surface treatments are processed, the appearance, hardness, corrosion resistance and chemical properties will be improved.

We machine rapid prototypes and low & large-volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.

The Basics Of CNC Lathes

CNC lathe machines sometimes referred to as live tooling lathes, are an excellent choice for creating symmetrical, cylindrical or spherical parts. These machines utilize a workpiece that rotates along a vertical or horizontal axis while a cutting instrument moves around it on a linear path. This cutting process is referred to as turning. As a result of their precision and efficiency, CNC lathes are often used in a variety of manufacturing environments.

How CNC Turning Works

CNC lathes use a subtractive method to achieve the desired shape, starting with the creation of G-Code. Once the G-Code is ready, a solid bar, or blank, of raw material is loaded into the chuck of the lathe’s spindle. The chuck securely holds the workpiece in place while the spindle rotates. Once the spindle reaches operating speed, a stationary cutting tool is introduced to the workpiece to remove excess material until the desired shape is achieved. This precise cutting method and advanced technology allow CNC lathes to create an array of shapes with high accuracy and consistency.

Types Of CNC Lathes

2-axis CNC lathes and Swiss-type lathes are the most prevalent types of lathes. However, Swiss-type lathes have unique features, such as stock material feeding through a guide bushing, which enables close-in cutting at the point of support. This attribute is suitable for slender, lengthy turned parts and micromachining. Additionally, some Swiss-type lathes are equipped with a second tool head that functions as a CNC mill. This feature saves costs since it allows the lathe to perform multiple machining operations without the need for another machine. As a result, Swiss-type lathes are cost-effective for complex turned parts.

CNC parts are integral to the production of industrial machinery used in automation, including CNC milling machines, laser cutting systems, and 3D printers. These machines rely on precision components such as ball screws, linear guides, and spindle assemblies to achieve accurate movement and machining operations.

CNC parts are crucial in the chemical industry for manufacturing components used in chemical processing equipment, reactors, storage vessels, and piping systems.

Yes , we could make sample based on drawing or customer demand.

Within 48 hours based on drawings time may different . Could add our whatsapp for a faster reply.

CNC turning parts , surface treatment , cold forging .