Hydraulic hose fittings are essential components in almost every industry. They create secure, leak-proof connections between hoses, pipes, and other components in hydraulic systems. With a wide variety of types and sizes, selecting the right hydraulic hose fitting can be challenging. This guide from Yuhuan Hongqian Machinery Co., Ltd, a leading industrial hydraulic fittings supplier in China, will help you choose, install, and maintain high-quality hydraulic hose fittings for long-lasting, safe operation.

What Is a Hydraulic Hose Fitting?

A hydraulic system uses pressurized fluid to transfer mechanical energy. The fluid flows through hydraulic hoses and is connected to machinery via hydraulic hose fittings.

These fittings must withstand high pressure and temperature, provide a secure seal, and prevent contamination. Some fittings allow fluid flow, others block it, and some perform both functions. The key purpose is to create a leak-proof connection.

Crimped Hydraulic Fittings & Field-Attachable Fittings

Crimped Fittings

Crimped fittings are permanently attached to hoses using a crimping machine. They provide durable, high-pressure connections ideal for industrial hydraulic systems. Modern portable crimpers allow for on-site installation, saving time for maintenance teams.

Field-Attachable Hydraulic Couplers

Field-attachable fittings (hydraulic couplers) can be installed without a crimping machine and reused multiple times. They offer convenience but usually have lower pressure ratings and can be potential failure points. For high-pressure systems, Yuhuan Hongqian Machinery Co., Ltd recommends permanent crimped fittings for safety and reliability.

Hydraulic Hose Fitting Materials

Choosing the right material ensures durability and safety. Common materials include:

-

Steel Fittings: High strength and durability, ideal for industrial and high-pressure applications.

-

Carbon Steel: Temperature range -53°C to 260°C, affordable but less corrosion-resistant.

-

Stainless Steel: Can handle -253°C to 648°C and pressures up to 20,000 psi; ideal for extreme environments.

-

Brass: Corrosion-resistant, cost-effective, suitable for medium-pressure applications (up to 3,000 psi).

Types of Hydraulic Hose Fittings

Hydraulic fittings vary by standard and type, depending on equipment and geographic standards.The most common type thread is america and british thread standard .

American Standards

-

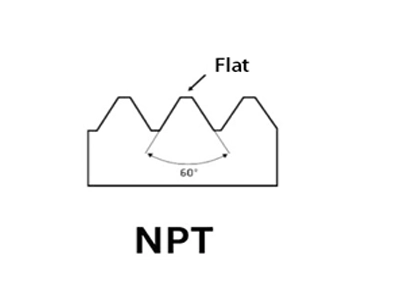

NPT: Tapered 1:16 threads for sealing, widely used in hydraulic systems,V-shaped threads (standard 60° included angle) .Tightens with sealing tape or compound; commonly used for liquids/gases.

-

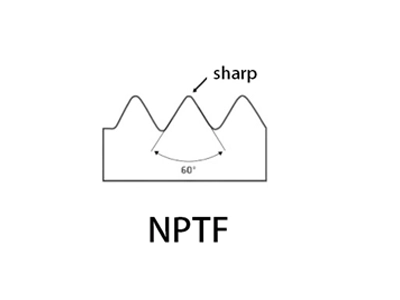

NPTF: Leak-proof metal-to-metal seal.Similar taper, but designed to seal without tape or compound. Thread interference creates a metal-to-metal seal.

-

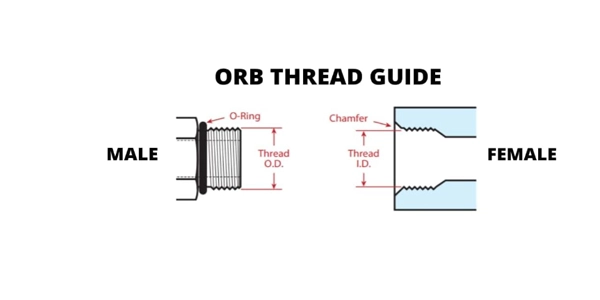

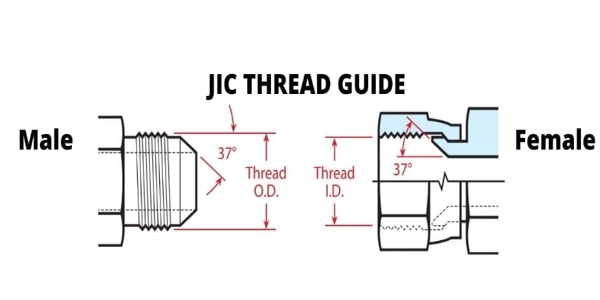

SAE: Includes ORB, JIC, and ORFS for high-pressure applications.

Hydraulic Fitting Standards and Connections

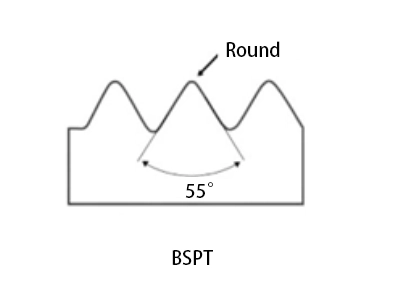

British & ISO Standards: BSP includes BSPT (tapered) and BSPP (parallel) threads, widely used in the UK and common industrial applications. ISO standards such as ISO 6162 and ISO 6149 use O-ring sealing to ensure leak-free, high-pressure hydraulic connections.

German Standards: DIN standards like DIN 7631, DIN 3902, and DIN 3852 define metric fittings with cone or thread seals, providing high interchangeability and reliable performance in European hydraulic systems.

Japanese Standards: JIS fittings include JIS PT threads and 4-bolt flanges. They are compatible with BSPT threads and often use O-ring seals, making them suitable for high-pressure applications in industrial and automotive hydraulics.

Hydraulic Hose Fitting Connections: O-Ring Face Seal (ORF/ORFS) fittings provide a high-pressure, leak-resistant seal and are ideal for critical hydraulic systems. Mated angle fittings, such as SAE 45° and JIC 37°, seal via a wedge effect and handle pressures up to 9,000 psi. Tapered thread fittings are typically used for low- to medium-pressure systems but are less suitable for high-pressure applications due to potential leakage.

How to Select the Correct Hydraulic Hose Fitting

Consider the STAMP factors:

Size: Ensure the hose diameter and thread type are correctly matched, as even slight mismatches can cause leaks, reduced flow, or premature failure in high-pressure hydraulic systems.

Temperature: The fitting must withstand both the system’s operating temperature and the surrounding environment, including extremes and fluctuations that could cause material fatigue or deformation.

Application: Take into account vibration, movement, and how often the fitting will be assembled or disassembled, selecting designs that maintain performance under stress and repeated use.

Assembly: Choose between crimped fittings for permanent, high-pressure connections or reusable fittings that allow for easier maintenance and flexibility without compromising safety.

Material: Select fitting materials that are compatible with the hydraulic fluid, resistant to corrosion, and durable enough to handle system pressures and environmental conditions over time.

Pressure: The fitting must exceed the system’s maximum operating pressure, providing a sufficient safety margin to prevent leaks, bursts, or failures during peak load conditions.

Fluid: Consider fluid compatibility and chemical resistance, ensuring that the fitting will not degrade, corrode, or contaminate the hydraulic fluid, maintaining long-term system reliability.

How to Install Hydraulic Hose Fittings

Select the Appropriate Fitting: Carefully choose a fitting that matches the hose size, thread type, pressure rating, and fluid compatibility to ensure a secure, leak-free connection for safe hydraulic operation.

Cut & Prepare the Hose: Use proper cutting tools to achieve a clean, straight hose end, removing any debris or burrs to prevent leaks and ensure the fitting seats correctly without damaging the hose.

Crimp or Assemble the Fitting: Depending on the type, either crimp the fitting with the correct die and pressure for a permanent connection, or assemble reusable fittings carefully following manufacturer instructions.

Visual Inspection: After assembly, check for proper alignment, tightness, and any visible defects, ensuring that the fitting is seated correctly and ready for system operation without leaks.

Protective Caps & Pressure Test: Install protective caps to prevent contamination during storage or installation, and perform a pressure test to verify the fitting and hose can handle the system’s maximum operating pressure.

Hydraulic Fitting Maintenance: Conduct regular inspections for wear, corrosion, and loose connections. Clean fittings with mild soap and warm water, tighten with a torque wrench, inspect hoses for damage, monitor fluid cleanliness, and store hoses in dry, cool locations.

Note: Crimped fittings are designed for one-time use only; reusing them can compromise system safety and lead to leaks or failures.

Hydraulic Hose, Fitting & System Experts

Yuhuan Hongqian Machinery Co., Ltd provides a full range of industrial hydraulic fittings, hose assembly, and hydraulic system solutions. From system design to training programs, our experts offer professional guidance and high-quality products for industrial clients worldwide.