Threads are one of the most critical components in mechanical assemblies and CNC metal parts, widely used in industries ranging from automotive to aerospace, plumbing, and heavy machinery. The wide variety of threads ensures that engineers and machinists can choose the right type for different applications, ensuring secure connections, durability, and precision. In this comprehensive guide, we will explore thread types, classifications, dimensions, and standards commonly used in high-precision CNC parts and pipe fittings.

1. The Diversity and Classification of Threads

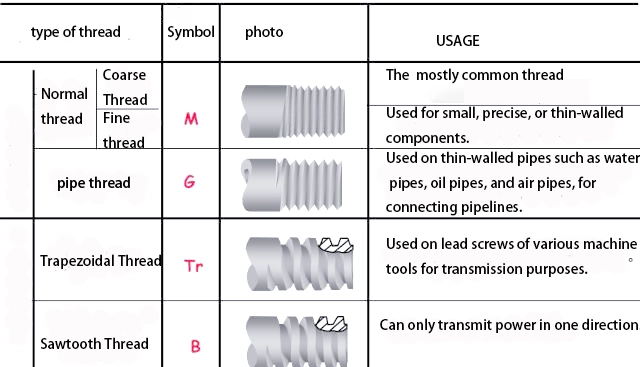

Threads can be classified based on shape, purpose, and standard. Each thread type has unique characteristics that make it suitable for specific applications. Broadly, threads can be divided into:

- Metric Threads (ISO Standard)

- Imperial Threads (US and British Standards)

- Pipe Threads (NPT, PT, G, and ZG threads)

- Specialty Threads (Square, Trapezoidal, Sawtooth)

Understanding the differences between these threads is critical for designing CNC parts, selecting pipe fittings, and ensuring proper assembly in mechanical systems.

2. Basic Elements of Threads

Every thread consists of five fundamental elements:

- Thread Profile – the shape of the thread cross-section.

- Nominal Diameter – the standard diameter representing the thread size.

- Number of Starts – the number of independent helices on a thread.

- Pitch and Lead – the axial distance between threads.

- Thread Direction – whether the thread rotates clockwise (right-hand) or counterclockwise (left-hand).

- These elements collectively determine the performance, strength, and precision of CNC machined threads.

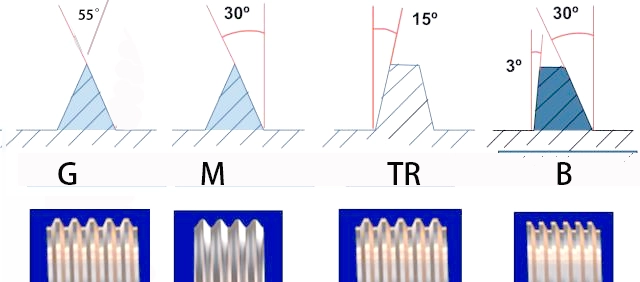

2.1 Thread Profile

The thread profile is a critical factor in thread strength and performance. Common profiles include:

- Triangular (V-shaped): Most commonly used for general fastening and CNC components.

- Trapezoidal: Offers high efficiency in power transmission; widely used in screw jacks and actuators.

- Sawtooth: Designed for unidirectional motion in heavy machinery.

- Round Threads: Common in light bulbs and rubber hose connections.

- Square Threads: Efficient for linear motion applications, such as vises and lifts.

The choice of thread profile depends on the application requirements, including load capacity, wear resistance, and ease of manufacturing.

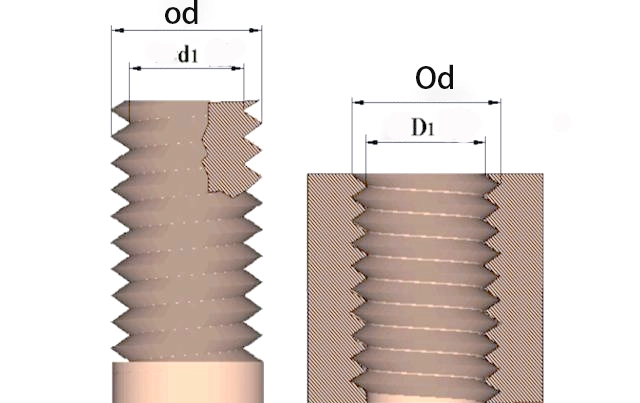

2.2 Diameter and Nominal Size

Thread diameters include:

- Major Diameter (d, D) – the outermost diameter of the thread.

- Minor Diameter (d1, D1) – the diameter at the base of the thread groove.

The nominal diameter usually represents the major diameter for standard threads. Correct diameter selection is critical for threaded pipe connections and high-precision CNC components.

2.3 Number of Starts

Threads can be single-start or multi-start:

- Single-start: One continuous helix; standard in most fasteners.

- Multi-start: Two or more helices evenly spaced, allowing faster assembly and load distribution. Common in precision screws and CNC machined parts requiring rapid engagement.

2.4 Pitch and Lead

- Pitch: Distance between corresponding points on adjacent threads.

- Lead: Distance between corresponding points on the same thread helix.

For single-start threads, lead = pitch. For multi-start threads, lead = pitch × number of starts. These parameters directly influence thread load capacity, speed, and performance.

2.5 Thread Direction

- Right-hand threads: Rotate clockwise; most common.

- Left-hand threads: Rotate counterclockwise; used in special applications to prevent loosening under rotation.

Choosing the correct thread direction ensures reliability in CNC assemblies and pipe fittings.

3. NPT, PT, and G Threads: International Pipe Standards

Pipe threads are designed to ensure tight sealing and mechanical stability in fluid and gas piping systems.

3.1 NPT Thread (National Pipe Thread)

- American standard, 60° tapered thread.

- Commonly used in North America for CNC parts and pipe fittings.

- Standard reference: GB/T12716.

- Suitable for high-pressure piping systems due to the tapered design.

-

Nominal Size (NPS) Threads per Inch (TPI) Major Diameter (OD) Pitch Diameter (PD) Minor Diameter (ID) Taper Pitch (P) 1/8" 27 10.242 mm 9.489 mm 8.737 mm 1:16 0.941 mm 1/4" 18 13.616 mm 12.487 mm 11.358 mm 1:16 1.411 mm 3/8" 18 17.055 mm 15.926 mm 14.797 mm 1:16 1.411 mm 1/2" 14 21.223 mm 19.772 mm 18.321 mm 1:16 1.814 mm 3/4" 14 26.569 mm 25.117 mm 23.666 mm 1:16 1.814 mm 1" 11.5 33.227 mm 31.461 mm 29.694 mm 1:16 2.209 mm 1-1/4" 11.5 41.984 mm 40.218 mm 38.451 mm 1:16 2.209 mm 2" 11.5 60.091 mm 58.325 mm 56.558 mm 1:16 2.209 mm 2-1/2" 8 72.699 mm 70.159 mm 67.619 mm 1:16 3.175 mm 3" 8 88.608 mm 86.068 mm 83.528 mm 1:16 3.175 mm

3.2 PT Thread (Pipe Thread)

- 55° sealing tapered thread, Whitworth family.

- Widely used in Europe and Commonwealth countries for water and gas pipelines.

- Taper ratio: 1:16, standard: GB/T7306.

- Provides reliable tightness and self-sealing in piping connections.

3.3 G Thread

- 55° cylindrical, non-sealing thread (Whitworth).

- Commonly used in general pipe fittings; standard: GB/T7307.

- Ensures stable connections without relying on thread taper.

3.4 ZG Threads

- Also called tapered pipe threads (Rc).

- Machined on a conical surface; widely used in standard water fittings.

- Ensures high sealing efficiency and stability.

Metric vs. Imperial Threads:

- Metric threads: Defined by pitch, typically 60° triangular profile.

- Imperial threads: Defined by threads per inch (TPI); 55° or 60° angles.

Correct selection of pipe threads is crucial for CNC components, piping systems, and fluid/gas tightness.

4. Thread Sizes, Tapers, and CNC Applications

- PT thread taper sizes: 1/16, 1/8, 1/4, 3/8, 1/2, 3/4. Each ensures precise fit and tight sealing.

- Pipe outer diameters: 1 ½, 2 ½, 3 ½, 4, critical for thread compatibility and high-precision CNC components.

The correct combination of thread size, pitch, and taper ensures reliability, durability, and safety in mechanical assemblies and piping systems.

5. Detailed Thread Types in CNC Parts and Pipe Fittings

5.1 Metric Threads (ISO Standard)

- Standard in China and internationally.

- Flat crests, rounded roots, 60° angle.

- Coarse and fine threads. Example: M8×1.25 (M = thread type, 8 = nominal diameter, 1.25 = pitch).

- Ideal for precision CNC metal parts.

5.2 US Standard Threads

- Flat crests and roots, 60° angle.

- Divided into coarse (NC), fine (NF), and extra-fine (NEF).

- Example: 1/2-10NC (1/2 inch major diameter, 10 TPI).

- Suitable for industrial CNC assemblies.

5.3 V-Threads

- Pointed crests and roots, 60° angle.

- Provides flexibility but lower strength; less common in heavy-load applications.

5.4 Whitworth Threads

- 55° angle, marked W, e.g., W1/2-10.

- Widely used in British-standard pipe fittings.

5.5 Round Threads

- Symbol: Rd; used in light bulbs and flexible hoses.

5.6 Pipe Threads

- 55° angle, self-locking, straight or tapered.

- Examples: P.S., N.P.S., N.P.T.NPTF

- Essential for leak-proof water and gas pipe connections.

5.7 Square Threads

- High efficiency for linear motion applications; used in vises, lifts, and jacks.

5.8 Trapezoidal / Sawtooth Threads

- Designed for unidirectional power transmission.

- Used in screw jacks, presses, symbol: Bu.

6. Conclusion: Choosing the Right Thread for CNC Parts and Pipe Fittings

Selecting the right thread type, size, and standard is essential for the performance and durability of CNC machined parts, pipe fittings, and industrial assemblies. Key considerations include:

- Application requirements: Load, speed, and environmental conditions.

- Thread standard: Metric, NPT, PT, G, or Whitworth.

- Precision: High-precision threads require tight tolerances and accurate manufacturing.

- Compatibility: Ensure male and female threads match properly to prevent leaks or mechanical failure.

By understanding thread types, dimensions, and international standards, engineers can ensure reliable, high-quality assemblies for a wide range of industrial applications.