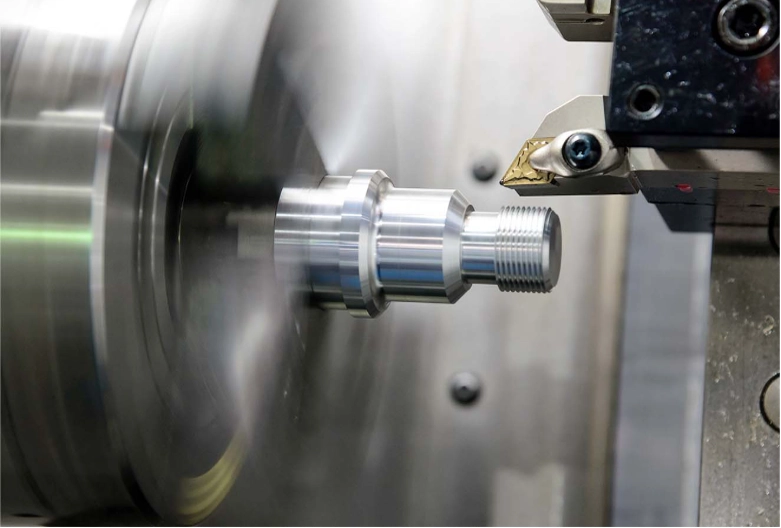

CNC turning parts are among the most widely used precision components in modern manufacturing. From hydraulic fittings and automotive shafts to electronic connectors and industrial fasteners, CNC turning plays a critical role in producing round, rotational, and high-tolerance parts at scale.

In this guide, we explain what CNC turning parts are, how the CNC turning process works, the most common turning operations, tools used, typical applications, and why CNC turning remains one of the most cost-effective machining solutions for industrial production.

What Is CNC turning ?

CNC turning is a machining process in which a cutting tool removes material from a rotating workpiece to produce cylindrical or rotationally symmetrical parts. The entire process is controlled by computer numerical control (CNC), ensuring high precision, consistency, and repeatability.

CNC turning vs milling (one-sentence comparison):

In CNC turning, the workpiece rotates while the cutting tool remains stationary, whereas in CNC milling, the cutting tool rotates while the workpiece is fixed.

Because of this fundamental difference, CNC turning is especially suitable for cnc machine shaft-type and rotational components, where concentricity, roundness, and diameter accuracy are critical.

Why CNC Turning Is Ideal for Shaft and Rotational Parts

The blank of CNC turning is not limited to producing perfectly round rods or tubes, it is a versatile machining process capable of handling a variety of shapes, including hexagonal bars, hexagonal tubes, elbows, and other standardized irregular blanks. This flexibility makes CNC turning ideal for creating complex components that meet precise industrial specifications.

In the china CNC turning operations, the mostly weide used system is huaxing and KND system for cnc lathe machine ,

In the system ,huaxing is operation by the x direction to control blank outdiameter size . z control the cnc parts length .

In KND system , then use the U equal to X , W equal to Z. The function is same , only different is system .

But for a more accurate production , KND system is better choice for thread produce .

Whether you are manufacturing standard rods or customized irregular components, mastering CNC turning processes ensures consistency, accuracy, and adaptability for modern industrial applications.

CNC turning is the preferred cnc process for:

-

After cnc turning could be get Cylindrical and round geometries

-

Parts with multiple diameters

-

Components requiring threads, grooves, or internal bores

-

High-volume production with tight tolerances ,

- economy cost ,suitable surface .

These advantages make CNC turning parts essential in industries such as hydraulics, automotive, aerospace, electronics, and industrial equipment manufacturing.

How CNC Turning Works

At its core, CNC turning relies on the relative motion between a rotating workpiece and a cutting tool.

Workpiece Rotation + Cutting Tool Principle

-

The raw material (bar stock or blank) is clamped in a chuck or collet.

-

The spindle rotates the workpiece at a programmed speed.

-

A cutting tool moves linearly along the X and Z axes.

-

Material is removed to achieve the desired shape, diameter, and surface finish.

-

All movements, feeds, and speeds are controlled by CNC programs, which ensures consistent quality across batches.

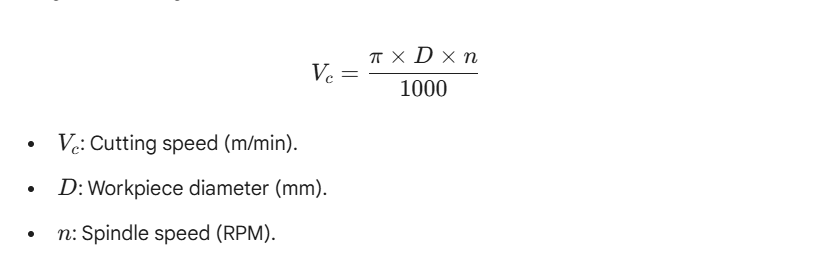

Technical Insight: Calculating Cutting Speed (Vc)

To achieve the precision defined in the program, operators must calculate the optimal cutting speed (Vc) using the following formula:

Optimizing these parameters is a cornerstone of machining excellence. A scientifically calibrated Vc significantly enhances surface finish (Ra) while balancing throughput with tool life. Especially in high-precision CNC turning, calculating the exact spindle speed based on material properties—such as stainless steel or aluminum—is essential to prevent thermal deformation and ensure dimensional consistency across high-volume production batches.

Basic Structure of a CNC Lathe

A typical CNC lathe consists of:

-

Spindle – rotates the workpiece

-

Chuck or collet – holds the material

-

Tool turret – indexes multiple cutting tools

-

Guideways – control tool movement accuracy

-

CNC controller – executes machining programs

Modern CNC turning centers often integrate additional functions such as live tooling, Y-axis movement, and automatic bar feeders, allowing complex parts to be completed in a single setup.

Common CNC Turning Processes (Overview)

Tool setting in CNC turning is the essential process of bridging the digital NC program with physical machining. Its primary goal is to establish the Workpiece Coordinate System (WCS) by defining the “Program Zero” (Part Origin) relative to the machine’s home position.

Key Components of CNC Tool Offsets:

-

Geometry Offsets: Defining the tool’s length (Z-axis) and diameter (X-axis).

-

Wear Offsets: Fine-tuning for tool pressure and tip wear.Tool wear causes product dimensions to drift; therefore, tool offset adjustments are required to compensate for this wear and bring the parts back within the specified drawing tolerances

-

Radius Compensation: Accounting for the tool nose radius during profiling based on the drawing demand .

Why Accuracy Matters: Accurate tool measurement ensures the cutting edge follows the programmed path with micron-level precision. Even a minor deviation in tool offsets can lead to:

-

Dimensional Inaccuracy: Resulting in scrapped workpieces.

-

Machine Collisions: Potentially causing thousands of dollars in spindle or turret damage.

CNC turning includes a wide range of operations that can be performed on the same machine.

Facing

Facing creates a flat surface perpendicular to the axis of rotation. It is usually the first operation to establish a reference face. It means you need

OD / ID Turning

-

OD (Outside Diameter) turning reduces the external diameter.

-

ID (Inside Diameter) turning, also called boring, enlarges or finishes internal holes.

Grooving

Grooving cuts narrow channels on the outer or inner surface, commonly used for O-rings, retaining rings, or functional clearances.

Groove cutting video

Threading

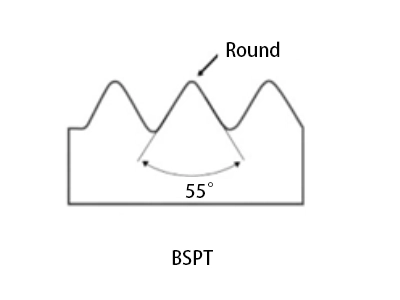

CNC turning supports:

-

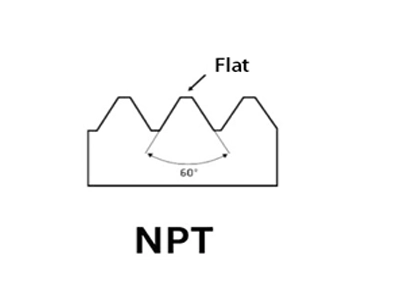

External threads (NPT, BSPP, metric, UNF, UNC etc) ,the different thread need choose the differnt type CNC cutting inserts , like Bspt ,you need choose the 55 degree cnc cuting inserts , Npt you need choose the 60 degree cutting inserts.

-

-

Internal threads for fittings and connectors

Thread accuracy is critical for sealing and assembly performance.

Drilling (on Lathe)

Drilling can be performed on the CNC lathe itself, eliminating secondary machining steps and improving efficiency.

Tools and Equipment Used in CNC Turning

The quality of CNC turning parts depends heavily on tooling selection.

Turning Inserts

Indexable inserts are used for:

-

Rough turning

-

Finish turning

-

Grooving and threading

Different insert geometries and coatings optimize tool life and surface finish.

Drills & Boring Bars

-

Drills create initial holes.

-

Boring bars improve internal diameter accuracy and roundness.

These tools are critical for tight-tolerance ID machining.

Live Tooling & Indexing

Advanced CNC turning centers may include:

-

Live tooling for milling features

-

Indexing for multi-face machining

This allows parts to be completed in one setup, reducing cost and lead time.

Common Challenges in CNC Turning Parts

Despite its advantages, CNC turning presents several manufacturing challenges.

Dimensional Variation

Causes include:

-

Tool wear

-

Thermal expansion

-

Improper machine calibration

Regular inspection and process control are essential to maintain tolerance consistency.Regular inspection and robust process control are essential for maintaining consistent tolerances. Strict compliance with drawing specifications is our commitment to delivering high-quality CNC turned parts to every customer

Surface Finish Issues

Poor surface finish may result from:

-

Incorrect cutting parameters

-

Dull inserts

-

Material inconsistencies

Surface finish directly impacts both aesthetics and functional performance. When the cnc cutting inserts get normal wear and tear , the suface will become rough ,for a good quality control , worker and inspection group need take careful for the surface . otherwise the goods may become defect products or need repair .

Burrs & Tool Wear

Burrs can affect :

-

Assembly

-

Sealing

-

Safety

Tool wear management is critical for stable mass production.Especially in stainless steel and carbon steel these high hardness fittings . We keep need big cost to reduce the burrs when some cnc turning steps is hard to remove the burrs .

Why CNC Turning is the Backbone of Precision Manufacturing

CNC Turning is the premier manufacturing process for producing high-precision cylindrical parts. By rotating the workpiece against a stationary cutting tool, manufacturers can achieve tight tolerances (up to ±0.005mm) and superior surface finishes that other methods simply cannot match. From OEM components to custom fluid power solutions, CNC turned parts are essential for reliability and performance.

Essential Industrial Components: CNC Turning Applications

This table highlights the most common CNC turned parts, focusing on their technical attributes and the industries that rely on them:

| Part Name | Technical Features & Specifications | Primary Industries |

| Pin | High-precision ground finish; exceptional roundness and straightness. | Aerospace, Robotics, Mold Making |

| Hose Fitting | Multi-stepped diameters for secure hose attachment and sealing. | Automotive, Pneumatics, Hydraulics |

| Pipe Joint | Heavy-duty wall thickness; precision-cut NPT, BSPP, or Metric threads. | Oil & Gas, Construction, Water Treatment |

| Tube Fitting | Designed for ferrule systems to ensure zero-leakage in gas systems. | Semiconductor, Medical, Chemical |

| Barbed Fitting | Precision-angled barbs for maximum grip on flexible tubing. | Medical Devices, Irrigation, HVAC |

| Hex Nipple | Machined from hexagonal bar stock for high-torque wrenching. | Plumbing, Pump Systems, Instrumentation |

| Bolt | High-tensile strength; custom head shapes and thread pitches. | Heavy Machinery, Infrastructure, Defense |

| T-Connector | Three-way flow distribution; smooth internal bore to prevent turbulence. | Fluid Power, Gas Distribution, HVAC |

| Elbow Fitting | 45° or 90° directional changes with precision-machined sealing faces. | Marine, Brake Systems, Cooling Circuits |

| Bulkhead Fitting | Extended thread length for panel mounting; includes precision locknuts. | Fuel Tank Systems, Enclosures, Marine |

| Hex Nut | Perfectly concentric threads to prevent loosening under vibration. | Power Generation, Rail, General Assembly |

| Steel Plug | Engineered for high-pressure sealing; internal/external drive options. | Engine Blocks, Hydraulics, Transmissions |

Conclusion

CNC turning parts are fundamental components in modern industrial manufacturing. With its ability to produce high-precision, rotational parts efficiently and consistently, CNC turning remains the preferred solution for shafts, fittings, threaded components, and many other critical parts.

Understanding CNC turning processes, tools, and applications helps engineers and buyers make better decisions when selecting machining suppliers and manufacturing methods.

If you are sourcing custom CNC turning parts or looking for a reliable CNC turning manufacturer, working with an experienced factory ensures quality, stability, and long-term supply performance.

Related topic :Why Inspection Methods Affect Product Accuracy in CNC Machining

What Is CNC Turning? A Practical Guide to Precision Turned Parts