Introduction

As a cnc parts manufacture , we are often face to custom different types of electroplating for satisfy customer drawings .

Electroplating is one of the most important surface treatment technologies in modern manufacturing. From corrosion protection and wear resistance to decorative appearance and functional performance, electroplating plays a critical role in extending product lifespan and improving overall quality.

In global industries such as automotive, machinery, electronics, aerospace, and hardware manufacturing, electroplated components are widely used to meet strict performance and durability requirements. As a mature yet continuously evolving surface engineering process, electroplating remains essential for manufacturers and OEM suppliers worldwide, especially in industrial production hubs such as China.

This article provides a comprehensive overview of common electroplating types, processes, materials, quality requirements, and industrial applications, helping engineers, purchasers, and manufacturers choose the right electroplating solution for their custom fittings.

What Is Electroplating?

Electroplating is a surface engineering process in which a thin, firmly bonded metal coating is deposited onto a substrate by means of direct current electricity. The process takes place in an electrolyte solution containing metal salts of the plating material.

In an electroplating system:

- The workpiece acts as the cathode

- The plated metal or an inert conductor acts as the anode

- A direct current drives metal ions to deposit onto the surface of the substrate

Through controlled electrochemical reactions, electroplating produces uniform, adherent metal layers with specific physical and chemical properties.

Why Is Electroplating Used in Manufacturing?

Electroplating is applied to improve both the appearance and functional performance of metal components. The main purposes include:

- Enhancing corrosion resistance

- Improving wear resistance and surface hardness

- Providing decorative finishes

- Improving electrical conductivity

- Enhancing solderability

- Adding optical, magnetic, or reflective properties

Because of its versatility, electroplating is widely used across industrial and consumer manufacturing sectors.

Main Categories of Electroplating Processes

Zinc Plating

Zinc plating is one of the most widely used electroplating processes in industrial manufacturing. Zinc is a chemically active metal that provides sacrificial (anodic) protection for steel substrates.

When steel parts are zinc-plated, zinc corrodes preferentially, protecting the base metal from rust even if the coating is damaged. Zinc plating is commonly applied to fasteners, brackets, hardware parts, and machinery components.

Zinc plating processes can be classified into:

- Cyanide zinc plating

- Non-cyanide zinc plating (alkaline zincate, chloride zinc, sulfate zinc)

Zinc coatings are often followed by passivation treatments to enhance corrosion resistance and improve appearance.

Blue-White Zinc Plating Yellow Zinc Plating

Copper Plating

Copper plating is typically classified as a cathodic coating, providing mechanical protection rather than sacrificial protection. Due to its excellent electrical and thermal conductivity, copper plating is widely used as an intermediate or underlayer in multi-layer plating systems.

Common copper plating processes include:

- Cyanide copper plating

- Sulfate copper plating

- Pyrophosphate copper plating

Copper plating is extensively used in:

- Printed circuit boards (PCB through-hole plating)

- Decorative metal products

- Precision mechanical parts

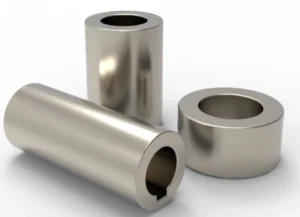

Nickel Plating

Nickel plating is one of the most important protective and decorative electroplating processes. Nickel has high hardness, excellent chemical stability, and strong passivation ability, allowing it to resist corrosion in many environments.

Nickel plating can be classified into:

- Ordinary nickel plating

- Semi-bright nickel plating

- Bright nickel plating

- Hard nickel plating

- Black nickel plating

To improve corrosion resistance, multi-layer nickel systems are commonly used, such as:

- Double-layer nickel (semi-bright nickel + bright nickel)

- Triple-layer nickel systems

Nickel plating is widely applied in automotive components, household appliances, medical instruments, tools, and decorative hardware.

Chromium Plating [chrome plating ]

Chromium plating offers excellent hardness, wear resistance, and aesthetic appeal. Chromium forms a stable passive film in air, allowing plated surfaces to retain their shine over long periods.

Chromium plating is divided into:

- Decorative chrome plating

- Hard chrome plating

- Micro-porous chrome plating

- Black chrome plating

Decorative chrome plating is usually applied over bright nickel layers, while hard chrome plating is used for functional purposes such as wear resistance and dimensional restoration.

Applications include:

- Shafts and cylinders

- Measuring tools and gauges

- Automotive and motorcycle parts

- Optical instruments

Tin Plating

Tin plating provides corrosion resistance, solderability, and non-toxicity, making it especially suitable for food containers and electronic components.

Tin coatings are generally categorized as:

- Alkaline tin plating

- Acid tin plating

Tin plating is widely used in:

- Food packaging (tinplate steel)

- Electronic connectors and terminals

- Electrical components requiring solderability

Silver Plating

Silver plating offers the highest electrical and thermal conductivity among all metals. It also provides excellent reflectivity and good solderability.

Silver plating is commonly used in:

- Electronics and electrical contacts

- Aerospace and instrumentation

- Reflective surfaces

- Decorative applications

To prevent tarnishing, silver-plated surfaces are often treated with anti-tarnish passivation or protective coatings.

Alloy Electroplating

Alloy electroplating involves the co-deposition of two or more metals to form a uniform alloy coating with enhanced properties compared to single-metal coatings.

Common alloy platings include:

- Copper-tin (bronze plating)

- Nickel-iron plating

Alloy coatings typically offer improved hardness, corrosion resistance, wear resistance, and decorative appearance. They are widely used in automotive, electronics, machinery, and precision instruments.

Chemical Nickel Plating

Chemical nickel plating, also known as electroless nickel plating, is a non-electrolytic deposition process that deposits a uniform nickel-phosphorus or nickel-boron alloy layer onto a substrate. Unlike traditional electroplating, this process does not require an external electrical current.

Advantages of chemical nickel plating include:

-

Uniform coating thickness even on complex geometries

-

Excellent corrosion resistance in harsh environments

-

Improved wear resistance and surface hardness

-

Good solderability and lubricity

-

Reduced risk of hydrogen embrittlement compared to electroplated nickel

Chemical nickel plating is widely used in:

-

Automotive components such as gears and bushings

-

Aerospace and defense parts requiring precision coatings

-

Electronics and semiconductor equipment

-

Mold and die surfaces for enhanced wear resistance

Zinc-Nickel Alloy Plating

Zinc-nickel alloy plating combines the corrosion protection of zinc with the enhanced hardness and durability of nickel, making it an ideal solution for steel substrates exposed to harsh environments.

Key characteristics of zinc-nickel alloy plating:

-

Sacrificial protection for steel similar to traditional zinc plating

-

Superior corrosion resistance, especially in automotive and marine applications

-

Higher hardness and wear resistance compared to pure zinc coatings

-

Excellent adhesion to steel and compatibility with post-treatment passivation

Zinc-nickel alloy plating is commonly applied to:

-

Automotive fasteners, bolts, and chassis parts

-

Industrial hardware and machinery components

-

Aerospace and defense applications requiring long-term corrosion protection with

Zn-Ni 12–15% Ni Alloy Plating

-

Thickness: 5–8 μm

-

Treated with chromate or trivalent (chromium-free) passivation

-

Salt spray test corrosion resistance: ≥240–480 hours, with automotive and industrial standards typically reaching 480 hours without red rust

Thicker coatings or higher nickel content (15–20% Ni)

-

Salt spray test corrosion resistance: 500–720 hours

Unpassivated or thin plated parts

-

Salt spray test corrosion resistance is shorter, generally 150–200 hours

Surface Preparation Before Electroplating

Proper surface preparation is essential to ensure coating adhesion and plating quality. Common pretreatment processes include:

- Chemical degreasing

- Solvent cleaning

- Electrolytic degreasing

- Acid pickling

- Mechanical polishing

- Sandblasting

Incomplete pretreatment often leads to plating defects such as peeling, blistering, or poor adhesion.

Common Electroplating Defects and Causes

Electroplating quality depends heavily on process control. Common defects include:

- Rough coatings caused by impurities or improper current density

- Burning due to excessive current or incorrect temperature

- Pinholes caused by hydrogen evolution or insufficient wetting agents

- Peeling and blistering due to poor pretreatment

- Uneven brightness caused by additive imbalance

Strict control of bath composition, pH, temperature, and current density is required to prevent these defects.

Post-Plating Treatments

After electroplating, post-treatment processes are applied to enhance performance and durability, including:

- Thorough rinsing and cleaning

- Hydrogen relief baking to prevent hydrogen embrittlement

- Chemical or electrochemical passivation

- Anti-tarnish treatment for silver coatings

- Organic protective coatings

Quality Requirements for Electroplated Coatings

High-quality electroplated coatings must meet the following criteria:

- Specified coating thickness

- Uniform appearance and fine grain structure

- Strong adhesion to the substrate

- No peeling, blistering, or severe defects

- Compliance with application-specific performance requirements

Quality inspection is especially critical for components used in demanding industrial environments.

Barrel plating VS rack plating in electroplating .

In industrial electroplating, choosing the right method for threaded components and fittings is critical to ensure functionality and surface quality. Barrel plating is suitable for small, low-demand parts such as internally threaded fittings, sleeves, and fittings without external threads. While barrel plating offers high production efficiency and low cost, the tumbling process can cause threads to be damaged, resulting in difficult assembly and compromised sealing performance.

Rack plating, on the other hand, is ideal for components that cannot tolerate surface damage, especially parts with high thread precision requirements. By suspending and securing each part during plating, rack plating prevents collisions, protects threads, and ensures smooth assembly and optimal sealing.

Understanding the differences between barrel and rack plating helps manufacturers select the most suitable electroplating method for threaded fittings, minimizing functional defects and ensuring consistent quality in automotive, hardware, electronics, and precision manufacturing applications in China and worldwide.

Comparison Table Framework (Threaded Components)

| Feature / Aspect | Barrel Plating | Rack Plating |

|---|---|---|

| Suitable Parts | Internally threaded fittings, sleeves, fittings without external threads | Components with high thread precision, surfaces that cannot be damaged |

| Surface Damage Risk | High; tumbling can cause scratches or thread damage | Low; fixed suspension prevents collisions |

| Thread Functionality | May cause difficult assembly, affect sealing | Maintains smooth assembly and optimal sealing |

| Production Efficiency | High-volume batches | Medium to small batches |

| Coating Quality | Uneven thickness, moderate surface finish | Uniform coating, high gloss, precise control |

| Cost | Low | Higher; requires racks and manual handling |

Industrial Applications of Electroplating

Electroplating is widely used across many industries, including:

- Automotive and motorcycle manufacturing

- Machinery and CNC components

- Electronics and electrical equipment

- Aerospace and defense

- Medical devices

- Hardware and tools

Its ability to enhance both performance and aesthetics makes electroplating indispensable in modern manufacturing.

Choosing the Right Electroplating Process

When selecting an electroplating process, manufacturers should consider:

- Base material

- Operating environment

- Required corrosion and wear resistance

- Appearance requirements

- Cost and production efficiency

Working with an experienced electroplating manufacturer or surface treatment supplier ensures optimal results.

Conclusion

Electroplating remains a core surface treatment technology in industrial manufacturing. By selecting the appropriate plating process and maintaining strict quality control, manufacturers can significantly improve product performance, durability, and market competitiveness.

As a key part of global manufacturing supply chains, professional electroplating services—especially those offered by experienced industrial suppliers in China—continue to support industries worldwide with reliable, cost-effective surface finishing solutions.